Plugging Method of Drain Pipe of Carbon Washing Tower in Coal-water Slurry Gasification Process

A carbon washing tower and drainage pipe technology, which is applied in the field of carbon washing towers, can solve the problems of excessive dust accumulation, time-consuming and labor-intensive effects, and poor results in carbon washing towers, and achieve the effects of prolonging the operation cycle, increasing equipment investment, and improving the flushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

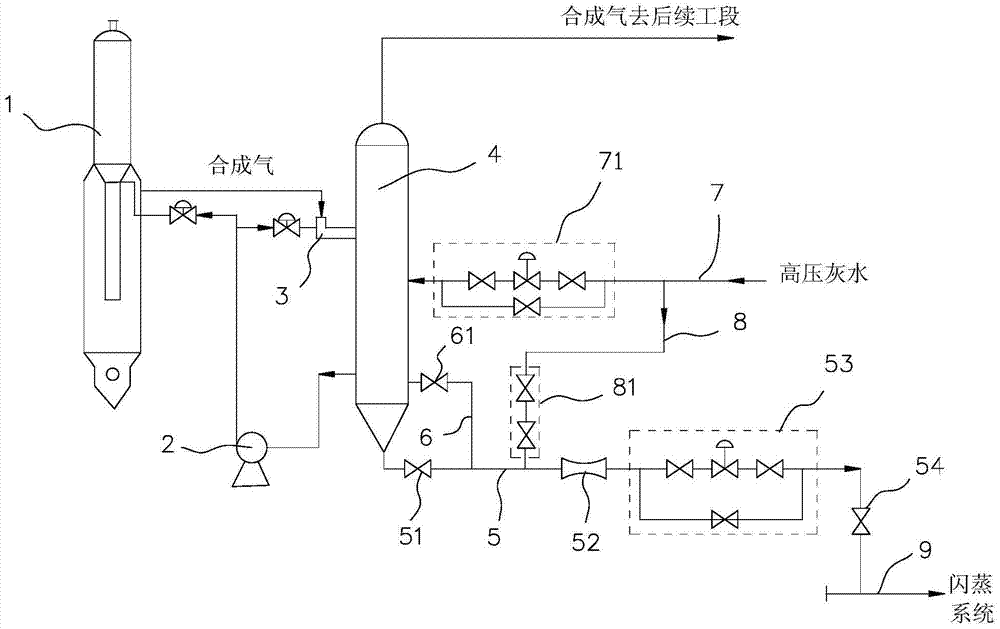

[0017] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings.

[0018] Process flow of the present invention such as figure 1 As shown, the drain pipe 5 at the bottom of the carbon washing tower 4 communicates with the high-pressure flash tank of the flash evaporation system through the drain main pipe 9, and the drain pipe 5 is successively equipped with a discharge valve 51, a flow meter 52, and a carbon washing tower drainage regulating valve group 53 And the main drain valve 54 of the carbon washing tower, the side drain pipe 6 connected with the drain pipe 5 is arranged at the lower part of the carbon washing tower 4, the side drain pipe 6 is equipped with a side drain valve 61, and the drain pipe 5 is connected between the discharge valve 51 and the flow meter 52 There is a flushing pipe 8 communicating with the supplementary water pipeline 7 of the carbon washing tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com