Pneumatic tire for bicycle

A technology for pneumatic tires and two-wheelers, applied in pneumatic tires, motorcycle tires, tire parts, etc., can solve the problems of narrow application range and insufficient driving performance, improve driving performance, suppress uneven wear, and improve the application range. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

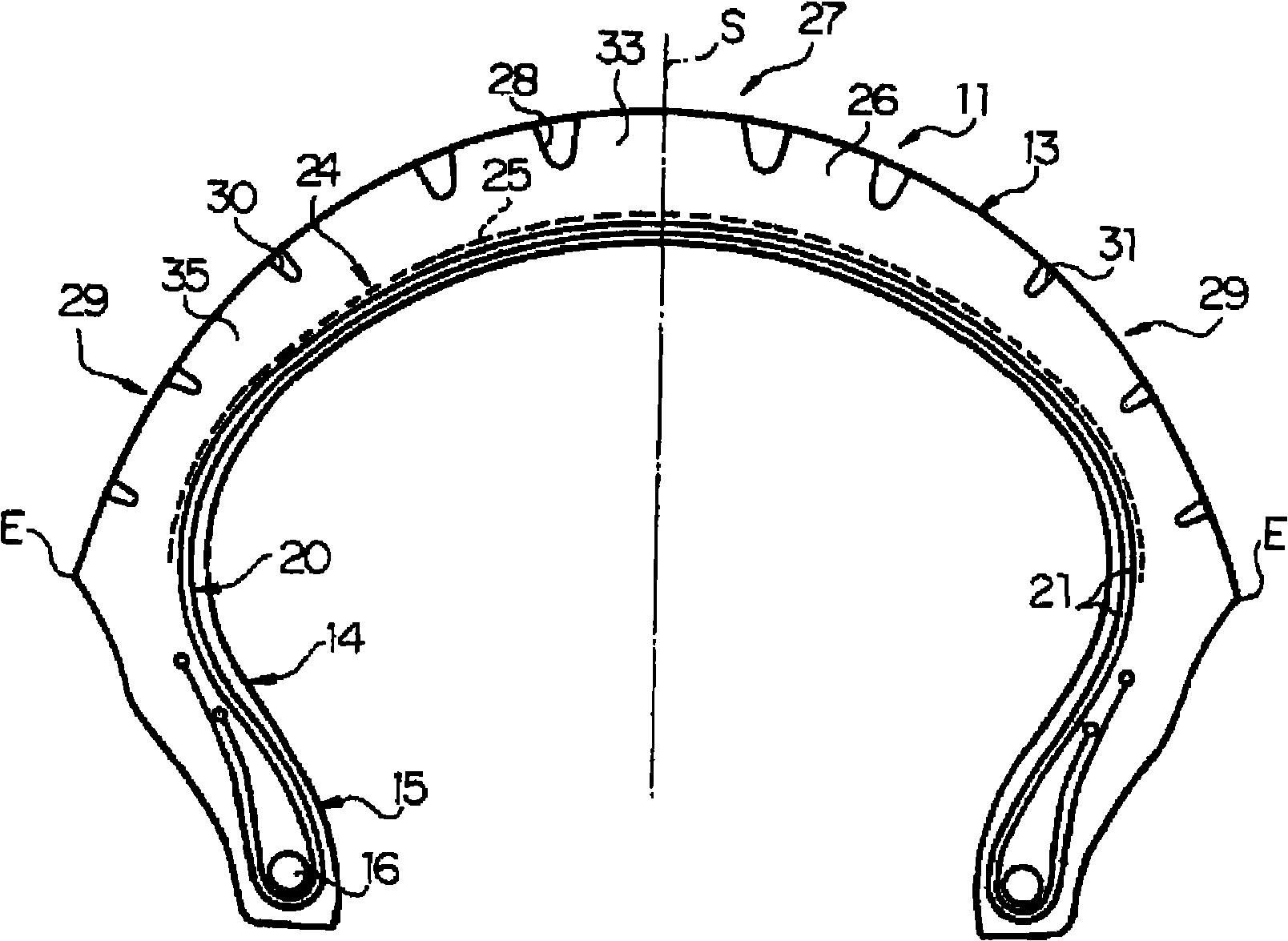

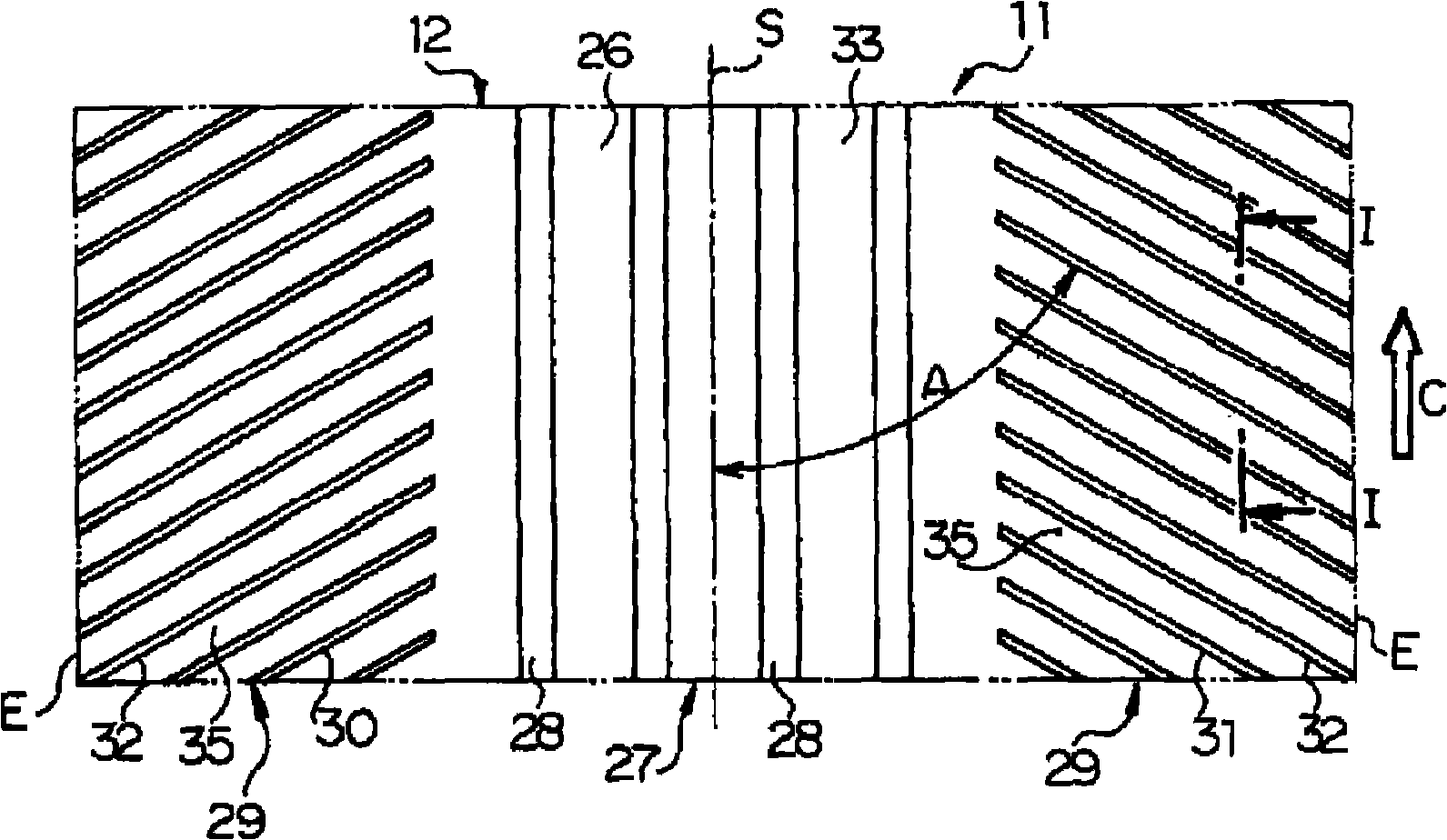

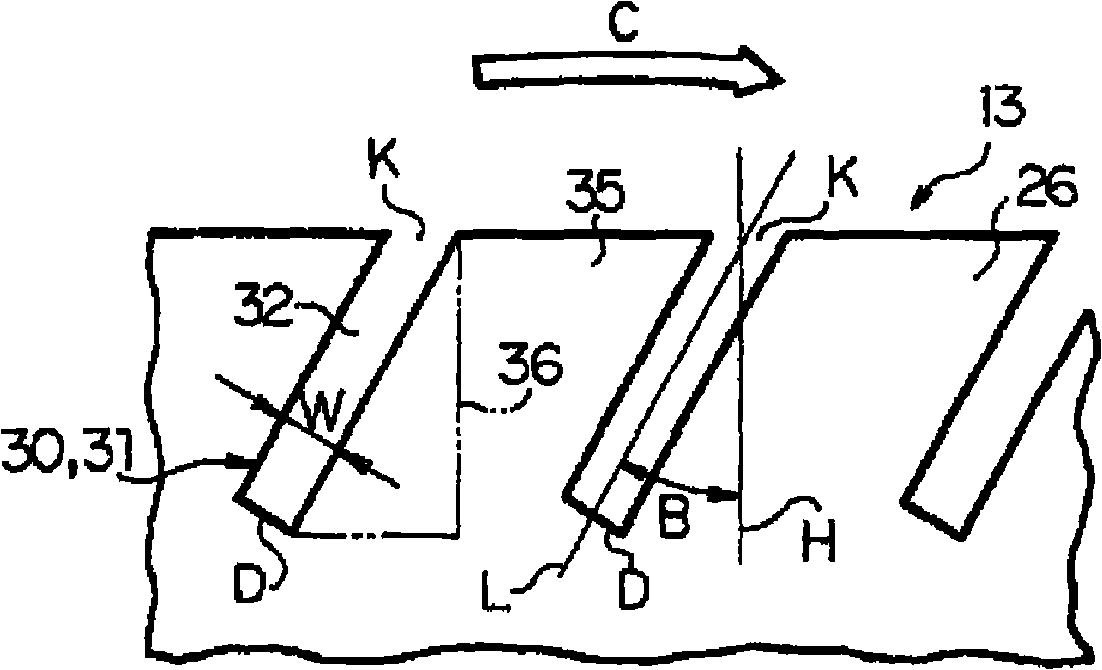

[0037] exist figure 1 , 2 In the figure, reference numeral 11 is a pneumatic tire for a two-wheeled vehicle suitable for high-speed running of a rear wheel whose direction of rotation is specified, and the tire 11 is formed by including a tread portion 13, a pair of sidewall portions 14, and A pair of bead portions 15; the meridian cross-section of the tread portion 13 is substantially arc-shaped, and is smoothly curved outward in the radial direction in a convex shape; the pair of sidewall portions 14 are generally directed toward Extending radially inward; the pair of bead portions 15 are continuous with the radially inward ends of the two sidewall portions 14, and respectively embedded with bead cores 16; the width between the tread ends E is taken as the maximum tire width.

[0038] In addition, the above-mentioned tire 11 further includes a carcass layer 20 extending in a curved shape between the pair of bead cores 16 to reinforce the sidewall portion 14 and the tread port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com