A kind of agarose crystal gel matrix particles with super large pores and preparation method thereof

A technology of matrix particles and agarose, which is applied in the field of agarose crystal gel matrix particles and their preparation, can solve problems such as lack of research and development, and achieve the effects of good permeability performance, rapid mass transfer and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

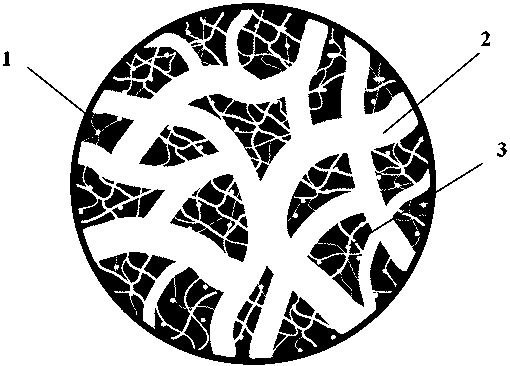

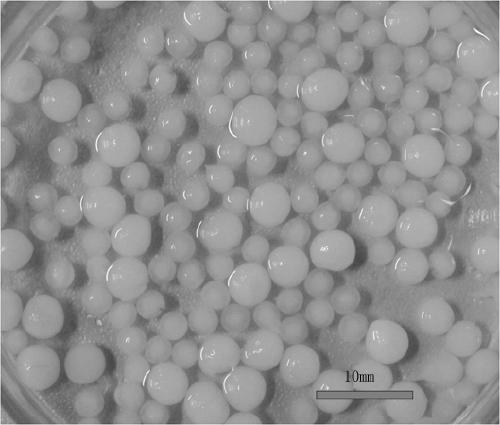

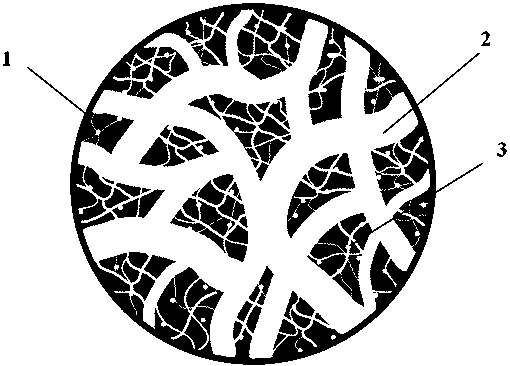

[0026] Dissolve 3 g of agarose in 97 mL of deionized water at 75-95 °C to make a 3% agarose solution; then, pass the obtained agarose solution through a multi-microtube reactor (microtube inner diameter 0.5 cm) at a flow rate of 5 cm / s. mm) to form droplets, freeze and crystallize in an ethyl acetate solution containing 3% Span 80 surfactant to form pores, and melt the ice crystals at room temperature to obtain a super-porous agarose crystal gel matrix. The actual morphology is as follows: figure 2 As shown, its cross-sectional enlarged structure is as follows figure 1 As shown, after measurement, the super-porous agarose crystal gel matrix has an average particle size of about 2 mm and a porosity of 97%. It is a submicron small pore 3, and the skeleton is surrounded by a large pore 2. As shown in the figure, the pore size of the super pore is 5~200 μm, and it has good elasticity in water.

Embodiment 2

[0028] Dissolve 6 g of agarose in 94 mL of deionized water at 75-95 °C to make a 6% agarose solution; then, pass the obtained agarose solution through a multi-microtube reactor (microtube inner diameter 2.2 mm) at a flow rate of 0.9 cm / s. mm) to form droplets, freeze and crystallize in ethyl heptanoate solution containing 2% Span 80 to form pores, and melt the ice crystals at room temperature to obtain a super-porous agarose crystal gel matrix. It is determined that the average particle size is about 4.3 mm, the porosity is 94%, and the colloidal matrix skeleton accounts for 6% of the total volume of the particles. There are submicron small pores in the skeleton, and the pore size of the large pores around the skeleton is 5~150 μm, which has good elasticity in water. .

Embodiment 3

[0030] Dissolve 6 g of agarose in 194 mL of deionized water at 75-95 °C to make a 3% agarose solution; then, pass the obtained agarose solution through a multi-microtube reactor (microtube inner diameter) at a flow rate of 4.2 cm / s. 2.2 mm) to form droplets, freeze and crystallize in a cyclohexane solution containing 80% by mass of Span to form pores, and melt the ice crystals at room temperature to obtain a super-porous agarose crystal gel matrix. The agarose granular crystal gel The schematic diagram of the structural cross-section of the matrix is as follows: figure 1 As shown, its actual shape is as follows figure 2 shown. The average particle size was determined to be about 5 mm, the porosity was 97%, and the colloidal matrix skeleton accounted for 3% of the total particle volume. The skeleton contained submicron small pores, and the large pores around the skeleton had a pore size of 5-200 μm, which had good elasticity in water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com