Preparation method of catalyst solid component for olefin polymerization

A technology for olefin polymerization and solid components, which is applied in the field of preparation of catalyst solid components for olefin polymerization, and can solve the problems of complex catalyst preparation process, low isotacticity of products, damage to male reproductive system and human immune system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] (1) alcoholate preparation:

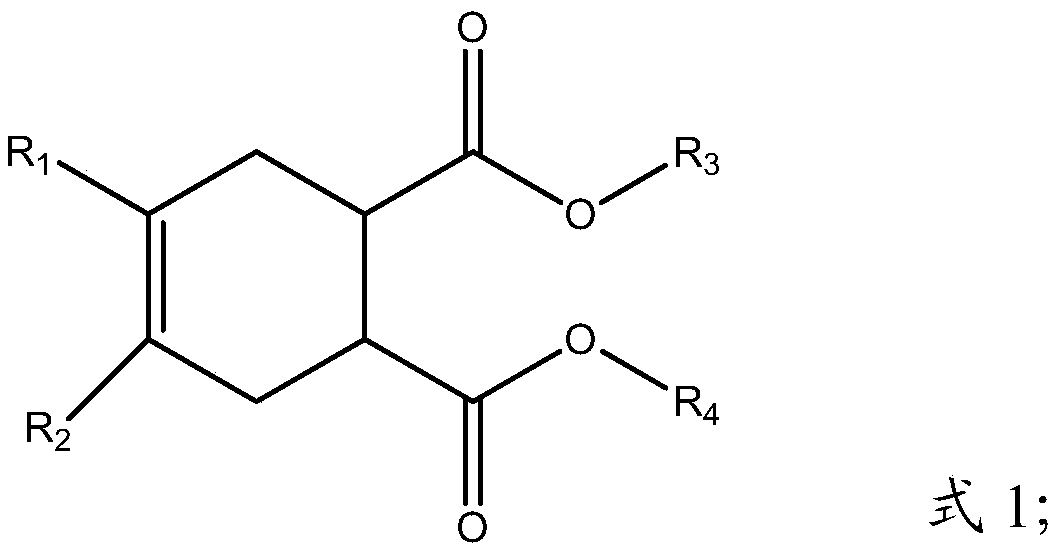

[0080] 5 g (about 0.05 mol) of anhydrous magnesium chloride, 23 mL (about 0.15 mol) of isooctyl alcohol, 30 mL (about 0.15 mol) of dry decane, 2 mL (about 0.0074 mol) of 1-cyclohexene-4,5-dicarboxylic acid Add di-n-butyl ester, 2.5g (about 0.0074mol) tetrabutyl titanate and 50mL dry toluene into the reaction flask, and react at 120°C for 4 hours under the protection of nitrogen to fully dissolve anhydrous magnesium chloride to obtain a stable and uniform Magnesium halide alcoholate solution.

[0081] (2) Solid catalyst preparation:

[0082] Under a nitrogen atmosphere, cool the homogeneous solution prepared above to -20°C, keep the temperature constant for 30 minutes, and gradually add 100ml (about 0.9mol) of titanium tetrachloride into the reactor within 1 hour. After the addition is complete, after 3.5 hours Raise the temperature to 110°C, add 2.5ml (about 0.0093mol) of di-n-butyl 1-cyclohexene-4,5-dicarboxylate, and react at this tempe...

Embodiment 2-5

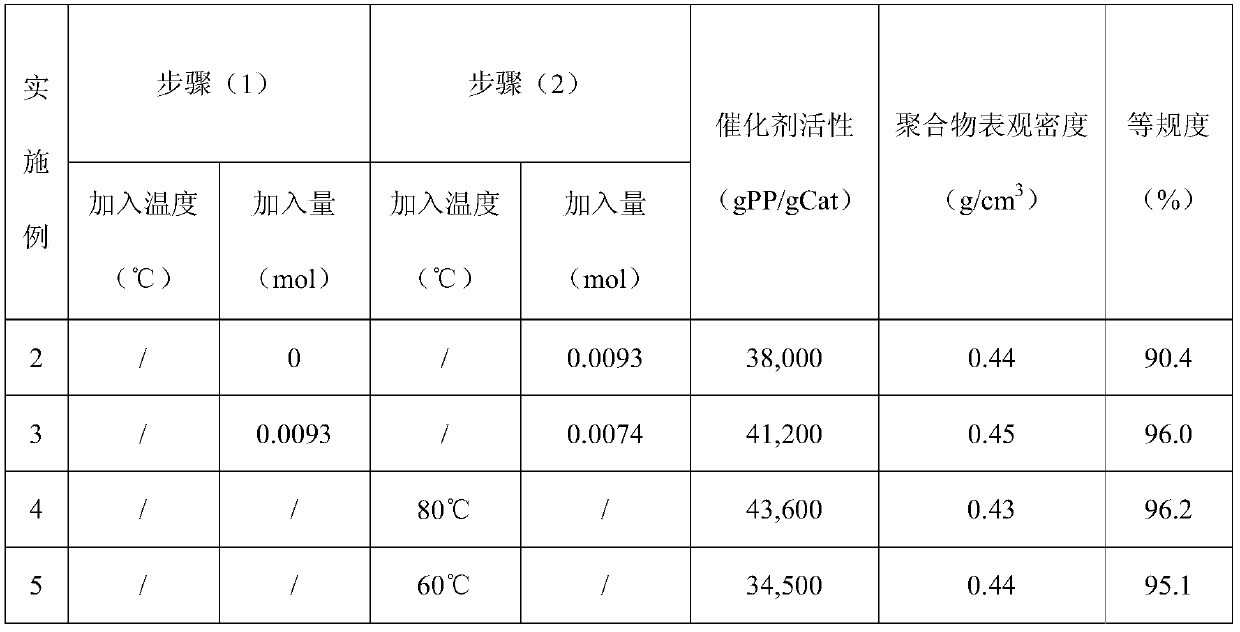

[0091] With the add-on of internal electron donor in step (1), step (2), the adding temperature of internal electron donor in step (2) is a variable, and other are all set embodiment 2-5 identically with embodiment 1, its result As shown in Table 1. Among them, " / " represents the unchanged factor.

[0092] The parameter change and experimental result of table 1 embodiment 2-5

[0093]

Embodiment 6

[0095] In Example 1, "1-cyclohexene-4,5-dicarboxylic acid di-n-butyl ester" was replaced by "1,2-dimethylcyclohexene-4,5-dicarboxylic acid diisobutyl ester", All the other are identical with embodiment 1.

[0096] Catalyst composition analysis results:

[0097] Titanium content: 2.65% (wt)

[0098] Magnesium content: 17.4% (wt)

[0099] Ester content: 7.2% (wt);

[0100] Polymerization result: catalytic activity 45,600gPP / gCat, polymer apparent density 0.45g / cm3 , The isotacticity is 97.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com