Energy-saving distillation system and method of chemical monomer

A rectification system and monomer technology, applied in chemical instruments and methods, chemical industry, organic chemistry, etc., can solve problems such as limiting the removal of towers and increasing the load of towers, so as to reduce feed volume, reduce load, Improve the effect of energy supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

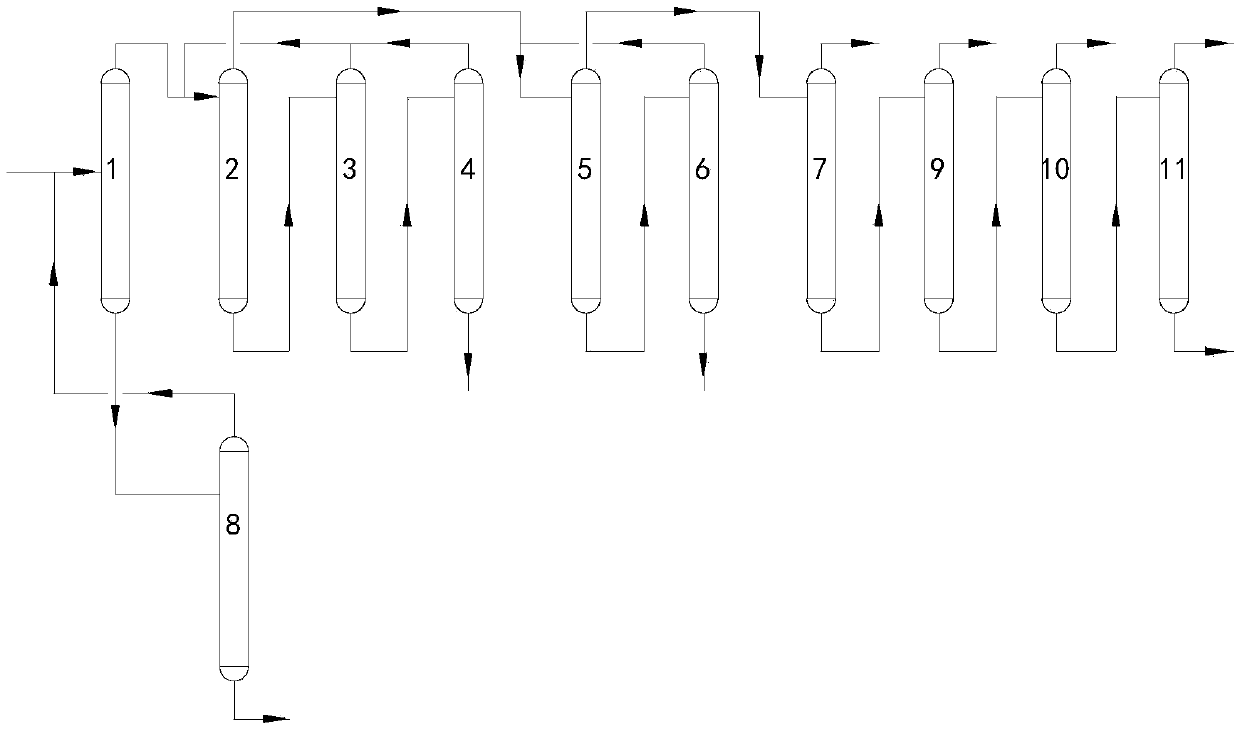

[0030] An energy-saving rectification system for chemical monomers, including a rectification system and a heating system, the rectification system such as figure 1 Shown, mainly comprise successively connected high tower 1, first tower 2, first tower 3, second tower 4, lower tower 5 and lower tower 6, wherein, first tower 2, first tower 6 The first lower tower 3 is connected in series with the second first tower 4, and the upper tower 5 is lowered and the lower tower 6 is lowered in series;

[0031] The inlet of the first upper tower 2 is connected with the tower top outlet of the lower tower 1, the tower top outlet of the first lower tower 3 and the tower top outlet of the second tower 4, and the tower top outlet of the first upper tower 2 is connected with the lowering The inlet of the upper tower 5, the outlet at the bottom of the first upper tower 2 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com