Method for extracting and separating nervonic acid

A separation method and technology of nervonic acid, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve the problems of low nervonic acid content, long cycle, complicated process, etc., and achieve high yield, low production cost and excellent process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

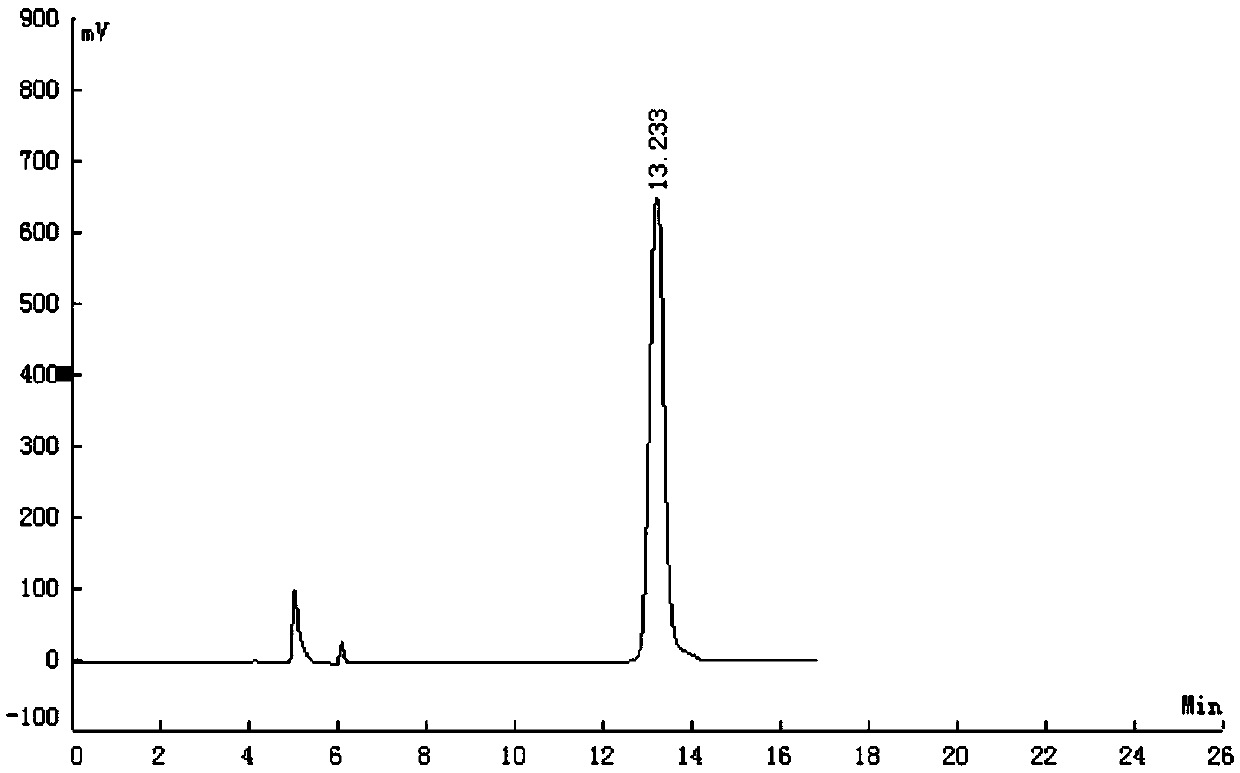

Embodiment 1

[0046] Embodiment 1: a kind of nervonic acid extraction and separation method comprises the following steps:

[0047] (1) extraction

[0048] (1.1) Get 100kg of maple ingot whose content of nervonic acid is 1% and pulverize;

[0049] (1.2) cross 10 mesh sieves through the raw material processed through step (1.1), then mix thoroughly with quicklime of 0.05 times raw material quality;

[0050] (1.3) extracting the raw material obtained through step (1.2) with n-hexane of 5 times the weight of the raw material, the extraction temperature is 45° C., and extracting 3 times, each time for 2 hours, to obtain the extract;

[0051] (2) concentrated

[0052] The extracts were combined and concentrated under reduced pressure until there was no n-hexane to obtain a concentrated solution;

[0053] (3) Acid adjustment

[0054] Add glacial acetic acid to the concentrate to make the pH of the concentrate=8;

[0055] (4) Extraction

[0056] (4.1) extracting the concentrated solution obt...

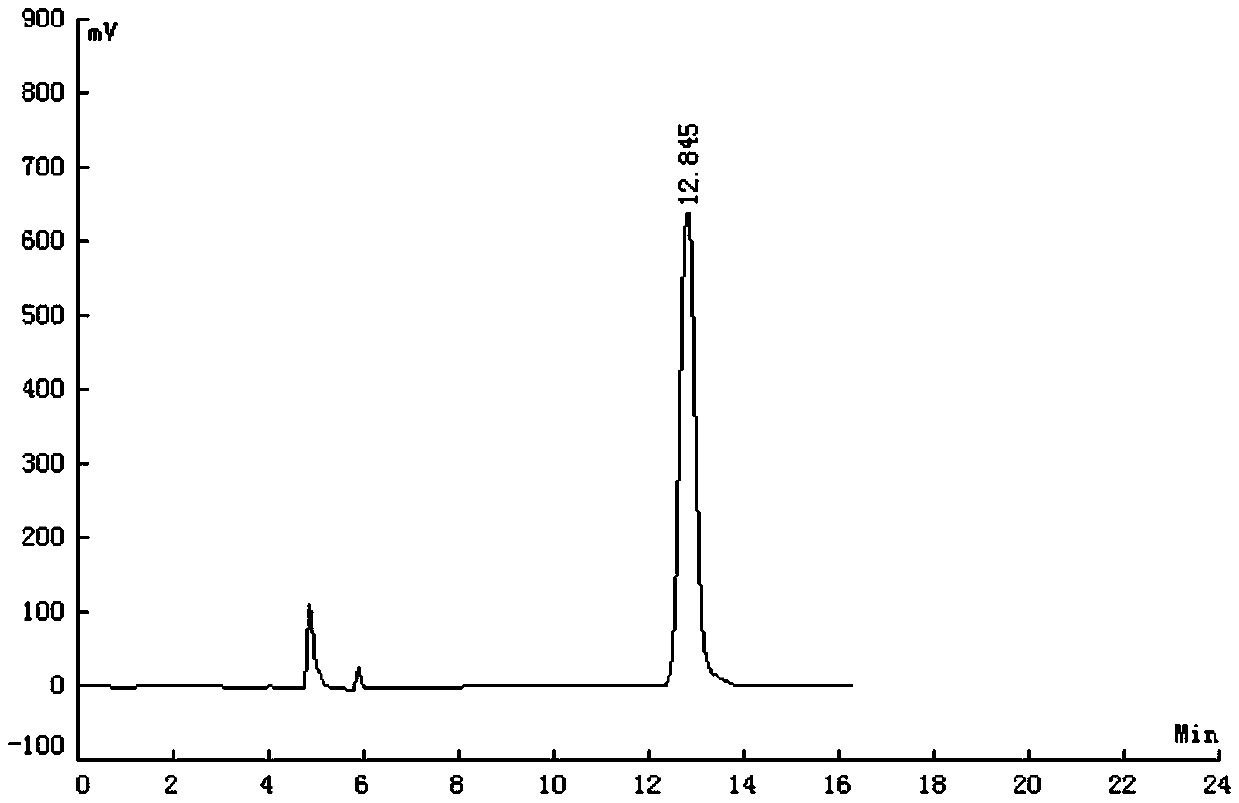

Embodiment 2

[0074] Embodiment 2: a kind of nervonic acid extraction and separation method comprises the following steps:

[0075] (1) extraction

[0076] (1.1) Get 100 kg of Vitex twig raw material with nervonic acid content as 2% and pulverize;

[0077] (1.2) cross 10 mesh sieves through the raw material processed through step (1.1), then mix thoroughly with quicklime of 0.07 times raw material quality;

[0078] (1.3) Extract the raw material obtained through the treatment in step (1.2) with n-hexane that is 8 times the weight of the raw material, the extraction temperature is 45° C., and extract 3 times, each time for 2 hours, to obtain the extract;

[0079] (2) concentrated

[0080] The extracts were combined and concentrated under reduced pressure until there was no n-hexane to obtain a concentrated solution;

[0081] (3) Acid adjustment

[0082] Add glacial acetic acid to the concentrate to make the pH of the concentrate=8;

[0083] (4) Extraction

[0084] (4.1) extracting the ...

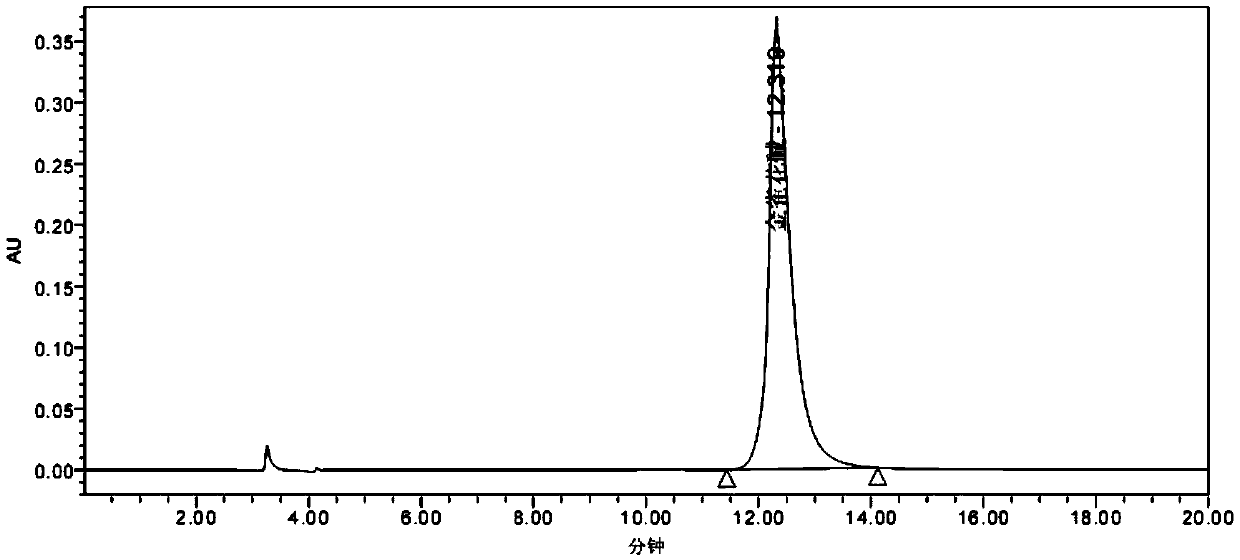

Embodiment 3

[0102] Embodiment 3: a kind of nervonic acid extraction and separation method comprises the following steps:

[0103] (1) extraction

[0104] (1.1) getting nervonic acid content is that 100kg of garlic fruit raw material of 5% is pulverized;

[0105] (1.2) cross 10 mesh sieves through the raw material processed through step (1.1), then mix thoroughly with unslaked lime of 0.1 times raw material quality;

[0106] (1.3) extracting the raw material obtained through the treatment in step (1.2) with n-hexane 10 times the weight of the raw material, the extraction temperature is 45° C., and extracting 3 times, each time for 2 hours, to obtain the extract;

[0107] (2) concentrated

[0108] The extracts were combined and concentrated under reduced pressure until there was no n-hexane to obtain a concentrated solution;

[0109] (3) Acid adjustment

[0110] Add glacial acetic acid to the concentrate to make the pH of the concentrate=8;

[0111] (4) Extraction

[0112] (4.1) extra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com