Light-colored self-peeling mold casting coatings and casting sand molds

A casting coating and light-colored technology, which is applied to casting molding equipment, coatings, casting molds, etc., can solve problems such as difficult to clean, easy to stick, difficult to sand, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Aggregate comprising 70% of cordierite powder, 10% of mullite powder, 20% of wollastonite powder, aluminum magnesium silicate accounting for 5% of aggregate weight, phenolic resin accounting for 2% of aggregate weight, accounting for 2% of aggregate weight % zinc oxide, 0.3% PVB by weight of aggregate, 0.1% surfactant by weight of aggregate, ball mill the three major aggregates to below 300 mesh, and add appropriate amount of ethanol to make light-colored self-stripping casting The Baume degree of the paint was 70, and a paint was obtained.

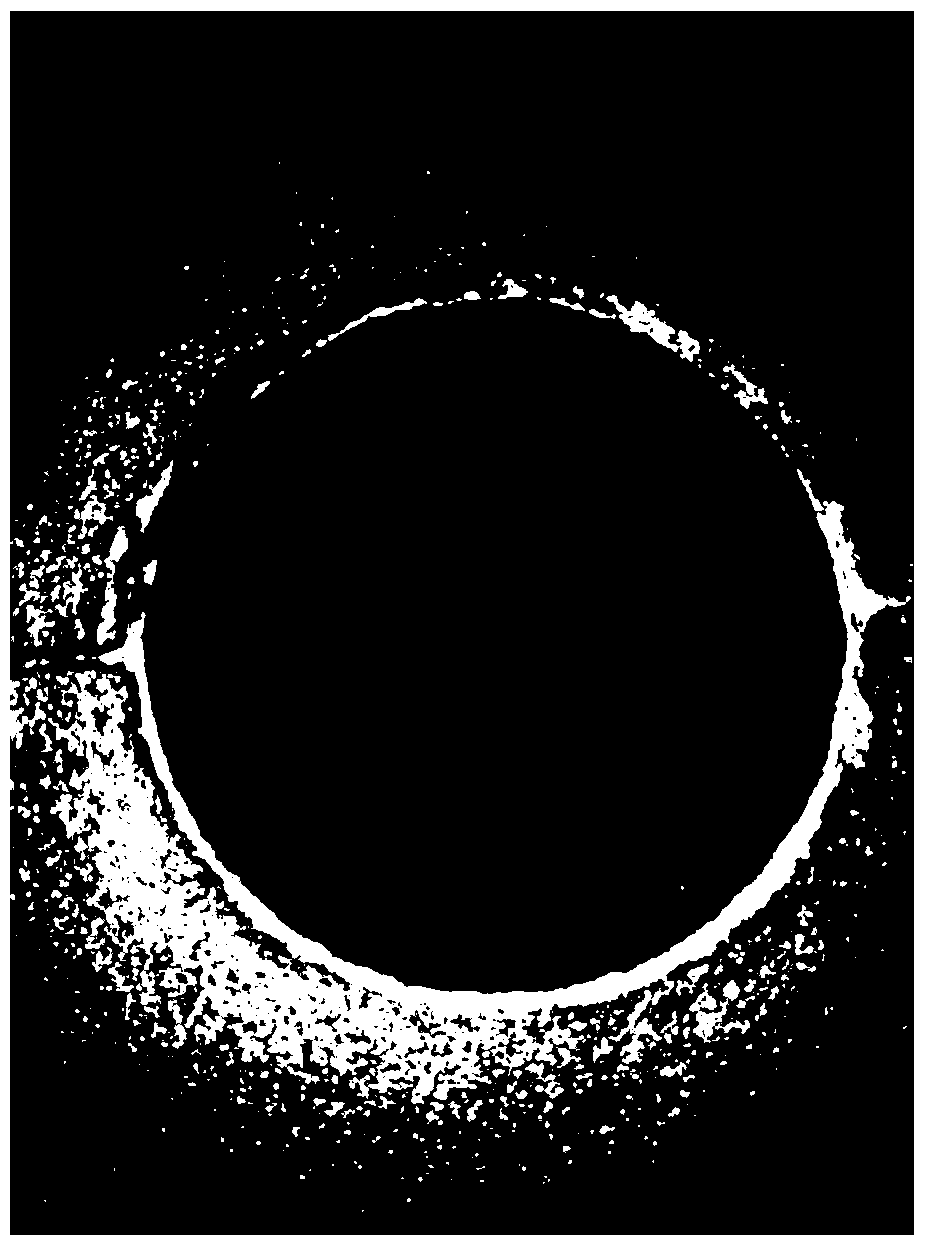

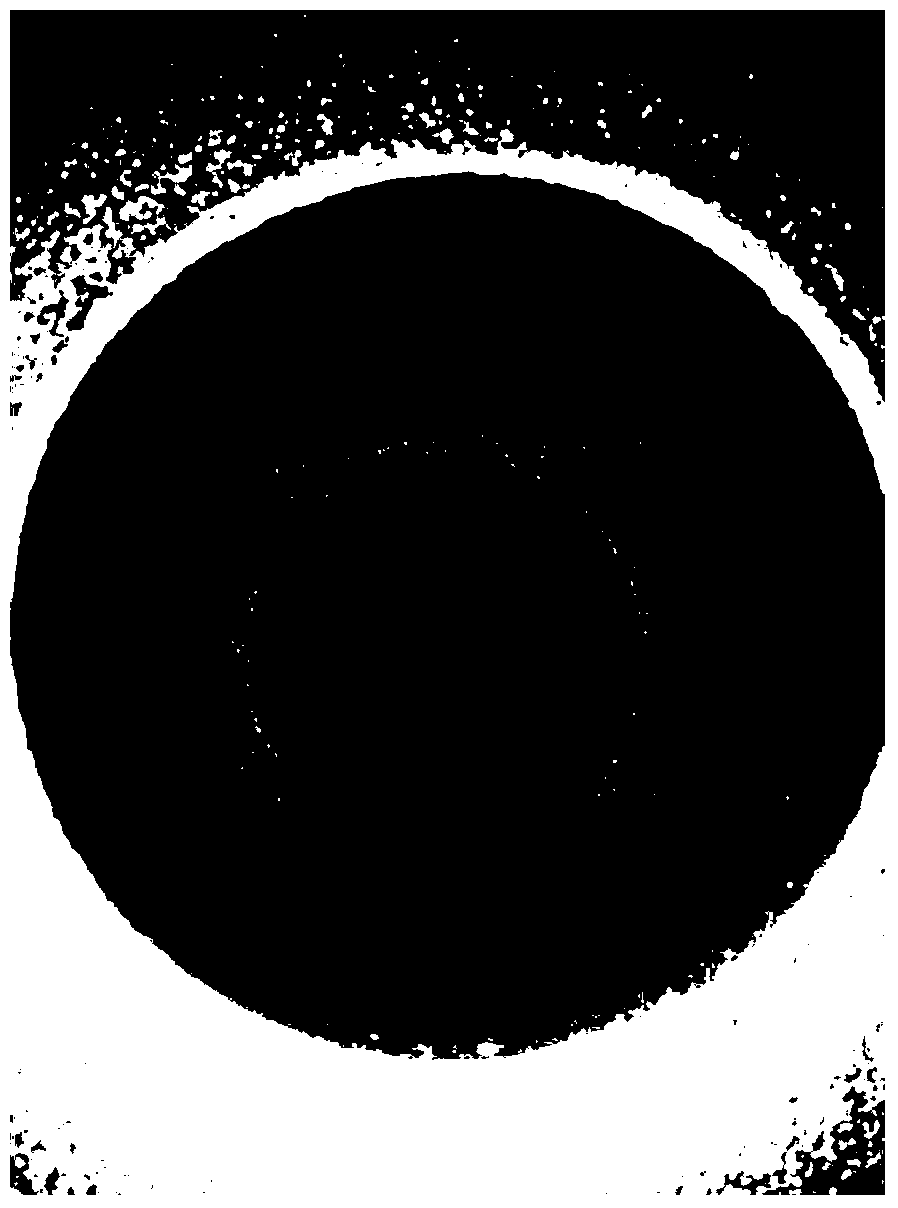

[0044] Apply the above-mentioned paint to the sand mold of the cylinder and cast it. The cylinder produced is as follows: figure 2 and image 3 shown. image 3 It is the topography of the cylinder produced by the light-colored self-stripping coating provided by the invention. Figure 4 for image 3 internal topography. Compare figure 1 , figure 2 and image 3 and Figure 4 , figure 1 It is the topography diagram of the ...

Embodiment 2

[0046] Aggregate will include cordierite powder 65%, mullite powder 15%, wollastonite powder 20%, aluminum magnesium silicate 5% by weight of aggregate, phenolic resin 3% by weight of aggregate, 3% by weight of aggregate % Zinc Oxide, 0.5% PVB by weight of the aggregate, 0.1% surfactant by weight of the aggregate, and ball mill the three major aggregates to below 300 mesh, add appropriate amount of ethanol to make the light-colored self-peeling type The Baume degree of the casting paint was 70, and the paint was obtained.

[0047] The above-mentioned paint is painted on the sand mold of the cylinder and cast, and the castings are produced without sticking phenomenon.

[0048] It can be seen from the above examples that when the light-colored self-stripping casting coating provided by the present invention is applied to castings with complex structures such as cylinder blocks, it has no adhesion to the castings and is easy to sand and clean up later.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com