In-situ preparation method and application of Ag/AgCl/NH2-MIL-101(Fe) composite photocatalyst with spindle appearance

An in-situ preparation and composite light technology, applied in the field of environmental pollution control, can solve problems such as large BET surface area, and achieve the effect of improving photocatalytic activity, widening the scope, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

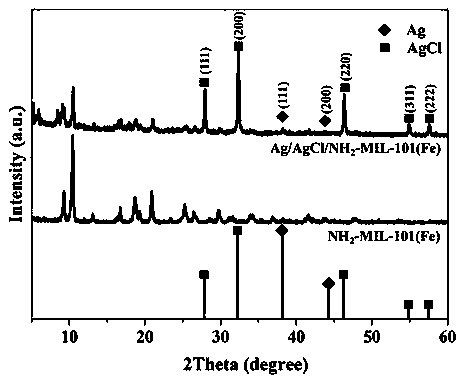

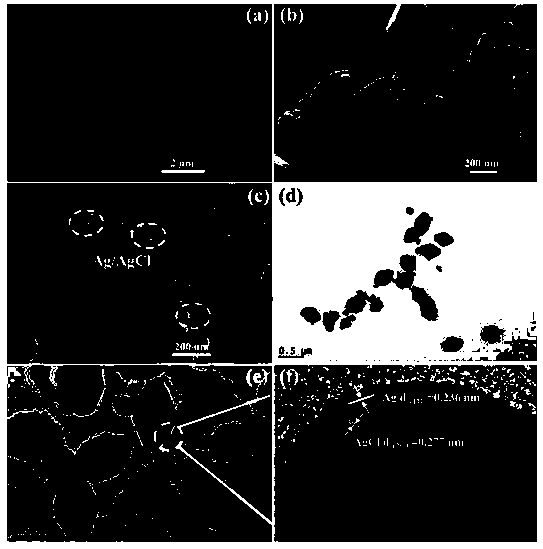

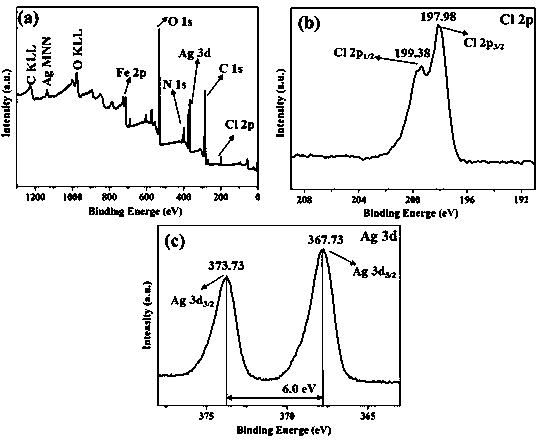

[0023] Embodiment 1: for the preparation method of this catalyst:

[0024] 1) NH with spindle morphology 2 -Preparation of MIL-101 (Fe) material: preparation by solvothermal method, at room temperature, ferric chloride hexahydrate (FeCl 3˙ 6H 2 O) and 2-aminoterephthalic acid (H2 ATA) dissolved in a certain amount of N,N - In dimethylformamide (DMF) (control the molar ratio of the three: 2:1:156), completely dissolve it by magnetic stirring to form a reddish-brown solution, transfer the mixture to 100mL polytetrafluoroethylene In an ethylene-lined reactor, react at 100°C or 110°C or 120°C for 15 or 20 or 25 or 30 hours, centrifuge after cooling, wash with DMF and ethanol three times respectively, and store at 50 or 60 or 70 or 80°C After vacuum drying for 4 or 6 or 8 or 10 h, a deep reddish-brown solid was obtained.

[0025] 2) Ag / AgCl / NH 2 -In-situ preparation of MIL-101(Fe) composite photocatalyst: This step is prepared in one step by ultraviolet light reduction method....

Embodiment 2

[0029] Example 2: Application of the composite visible light photocatalyst in degrading gas phase VOCs

[0030] According to the Ag / AgCl / NH of the present invention that the preparation method of embodiment 1 makes 2 -MIL-101(Fe) composite photocatalyst, the experiment of photocatalytic degradation of toluene with gaseous organic pollutants was carried out, the reaction was carried out in a self-made quartz reactor, and the reaction process was monitored in situ by infrared spectrometer.

[0031] 1) Fourier transform infrared spectrometer

[0032] In this experiment, the German BRUKERVERTEX70 Fourier transform infrared spectrometer was used to monitor Ag / AgCl / NH 2 - Reaction process of MIL-101(Fe) composite visible light photocatalyst for photocatalytic degradation of gas phase toluene under visible light.

[0033] 2) In situ infrared reaction cell

[0034] It is an in-situ infrared reaction cell designed and processed by ourselves. The entire reaction cell is made of quar...

example 1

[0044] The composite visible light photocatalyst prepared in Example 1 has visible light activity and can be excited by visible light. The recombination probability of photogenerated electron-hole pairs is reduced through the LCCT effect and loading, and the degradation ability of pollutants is effectively improved. Ag / AgCl / NH prepared by the present invention 2 -MIL-101(Fe) composite photocatalyst has strong oxidation ability and high catalytic activity, and has potential application prospects in sewage treatment, air purification and other fields.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com