Reaction kettle and three-phase flow catalytic reaction method applying same

A reaction kettle and reaction technology, applied in chemical instruments and methods, chemical/physical/physical chemical nozzle reactors, chemical/physical processes, etc. Process steps and other issues to achieve the effect of increasing the contact area of raw materials, simplifying equipment and processes, and accelerating the mixing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

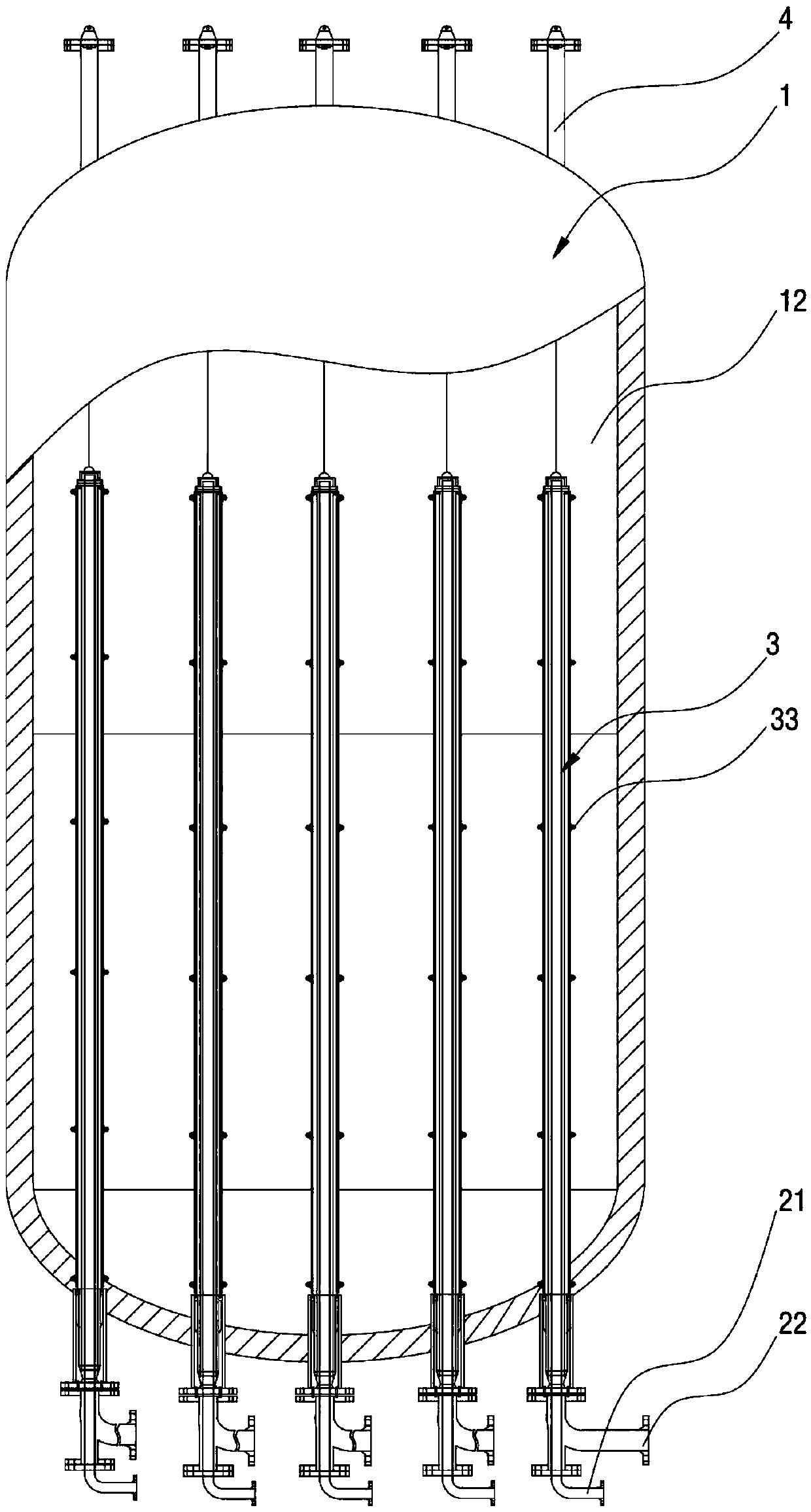

[0054] Example as Figure 1 to Figure 3 shown.

[0055] Such as figure 1 As shown, the reaction kettle in Embodiment 1 includes a kettle body 1 , which is surrounded by a shell to form a structure with a cavity inside, and the cavity in the kettle body 1 is a reaction chamber 12 .

[0056] Wherein the position of the lower bottom end of the kettle body 1 is connected with a plurality of feeding ports 21 and discharging ports 22 which are independent of each other. In addition, each feed port 21 and each discharge port 22 are set independently of each other. Of course, the upstream of each feed port 21 is connected to a main channel for raw material transportation. Correspondingly, each of the discharge ports The downstream of port 22 is commonly connected with a trunk passage for conveying finished products.

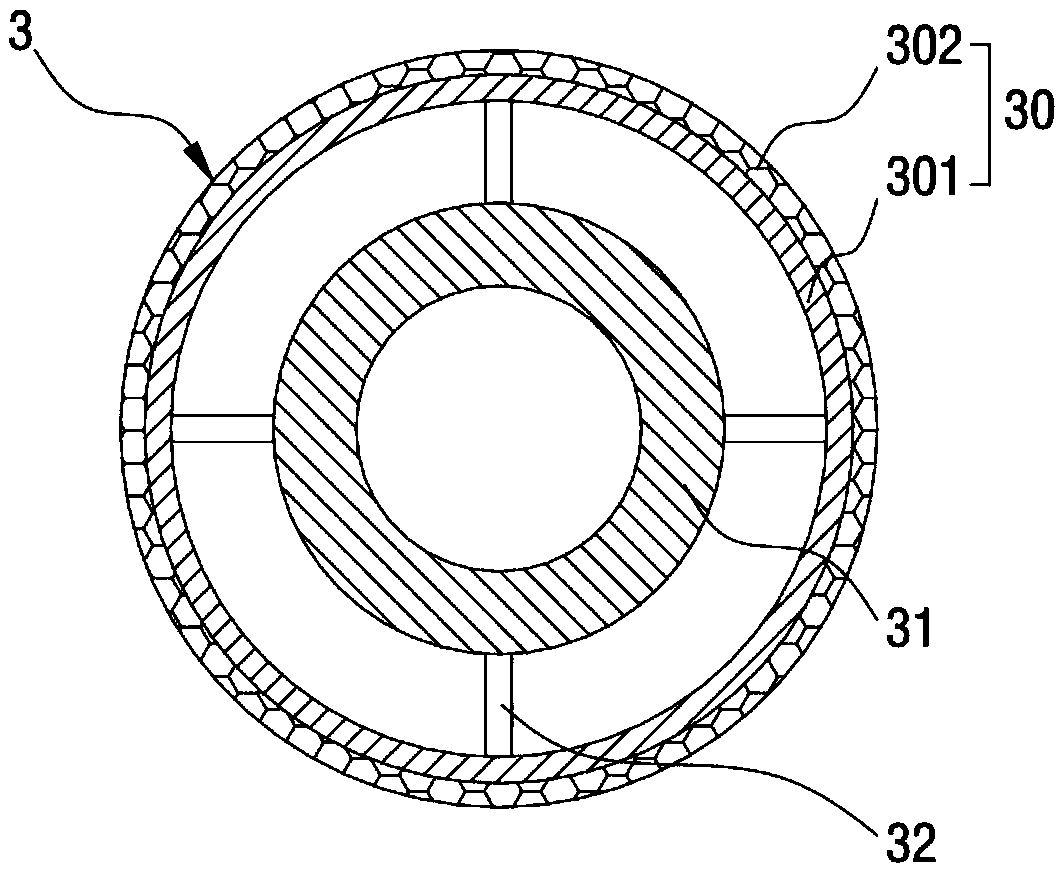

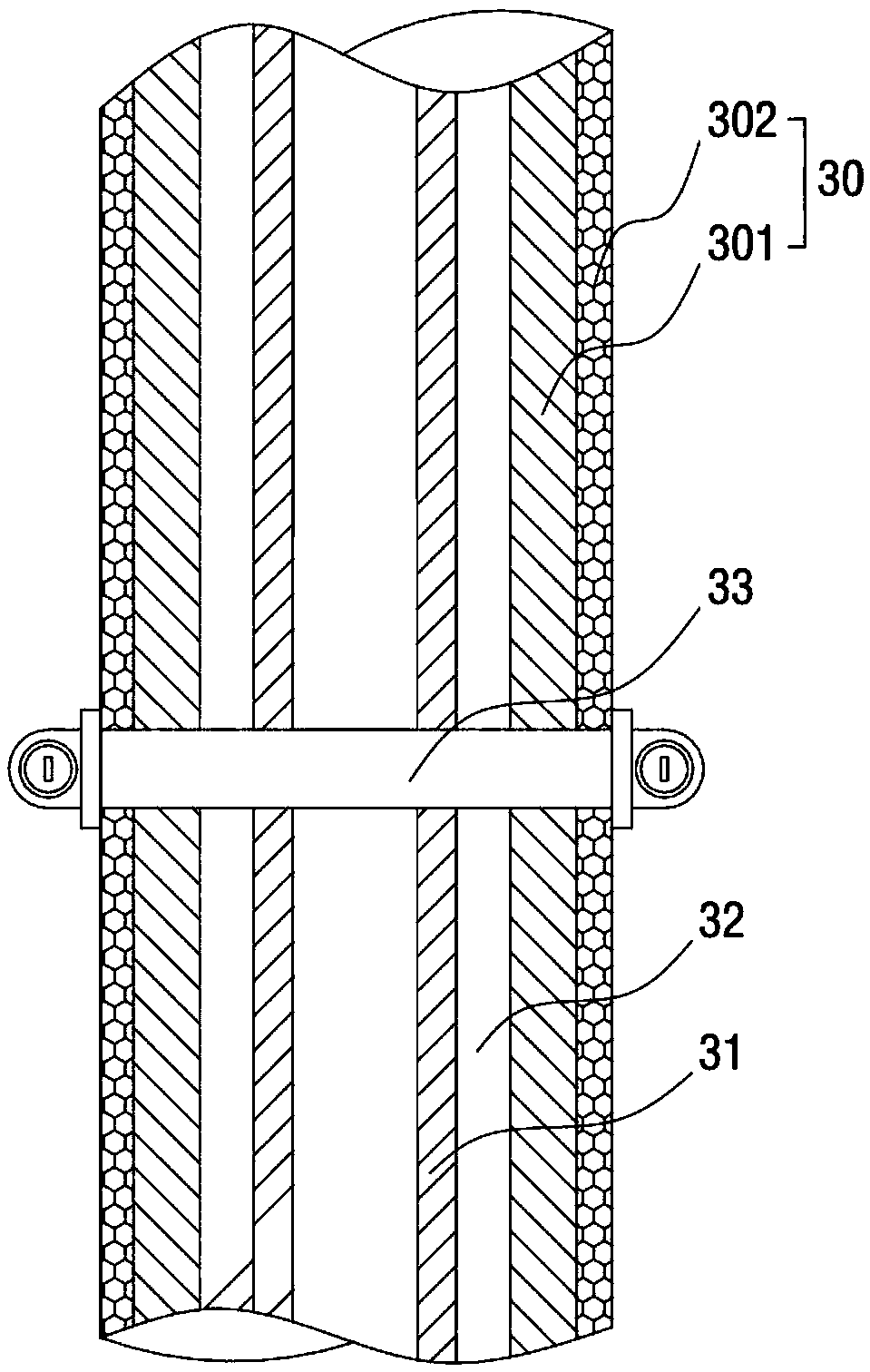

[0057] At the same time, in the first embodiment, a plurality of vertical tubular structure guide structures 3 are placed in the reaction chamber 12 in the kettle bod...

Embodiment 2

[0076] Example two such as Figure 4 As shown, the reaction kettle in this embodiment includes a kettle body 1, and the kettle body 1 is provided with a reaction chamber 12, and the reaction chamber 12 includes a plurality of pipe-shaped flow guide structures 3, and the flow guide structure 3 includes the permeable component 30 composed of the flexible porous metal foil used above as the filter material 302 pasted on the first support body 301.

[0077] Some of the diversion structures 3 are divided into two types, one is that the first diversion structure 3a is located in the reaction chamber 12 and communicates with the feed port 21; the other is that the second diversion structure 3b is located in the reaction chamber 12 And communicate with the discharge port 22. After passing the reactants from the first flow guide structure 3 a into the reaction chamber 12 for reaction, they are discharged from the second flow guide structure 3 b through the outlet 22 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com