an emulsifying machine

A technology of emulsifying machine and emulsifying tank, applied in the field of emulsifying machine, can solve the problems of small impact force of emulsifying tank, single material movement trajectory, poor stirring effect, etc., and achieve the effect of enhancing emulsifying ability and improving emulsifying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

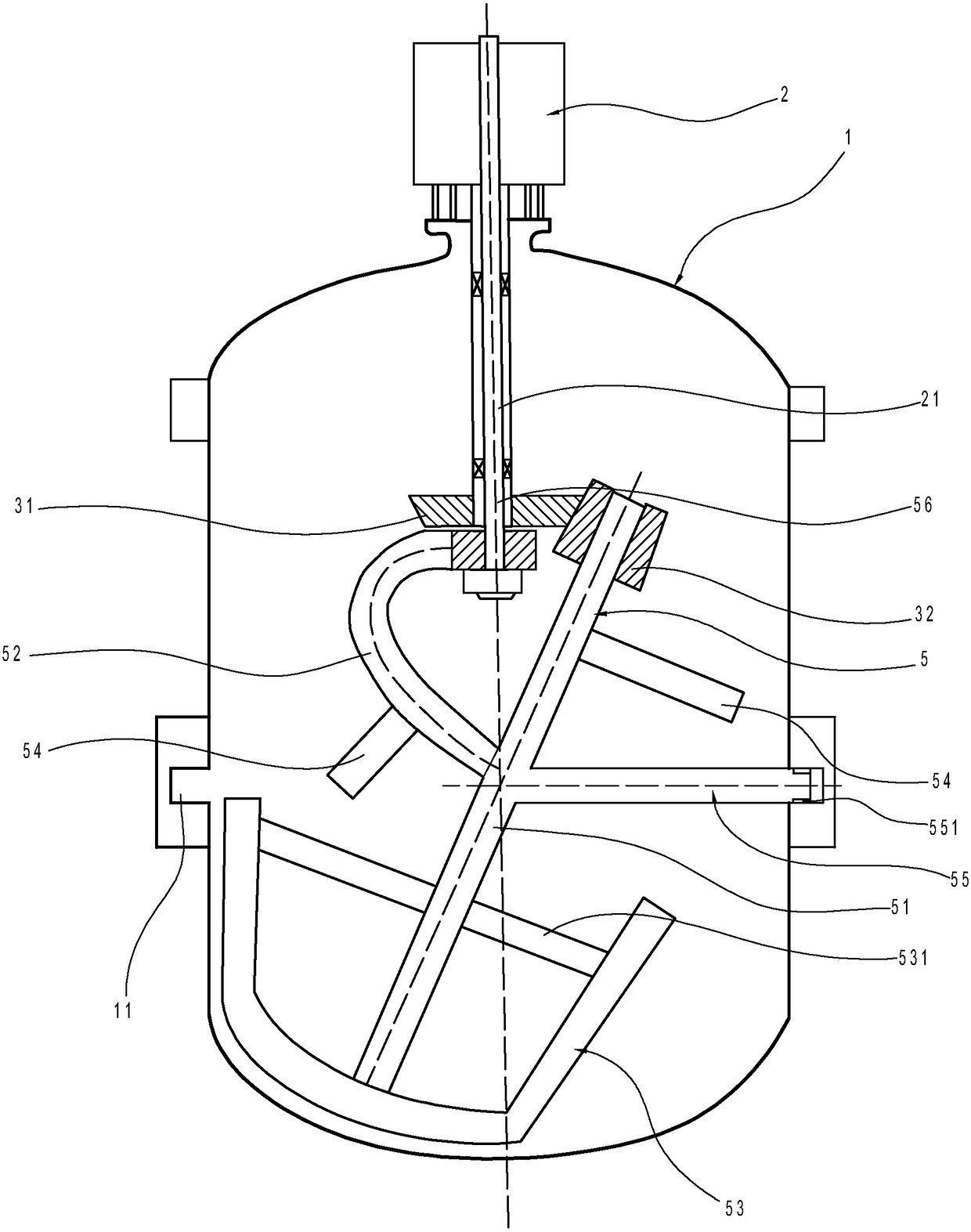

[0013] Such as figure 1 As shown, the emulsification machine in this implementation includes an emulsification tank 1 , a driving motor 2 and an emulsification assembly 5 .

[0014] Wherein, the drive motor 2 is arranged outside the emulsification tank 1 , and the emulsification assembly 5 is placed inside the emulsification tank 1 . The driving motor 2 is a hollow motor, and the driving motor 2 includes a drive shaft 21 arranged longitudinally. Be located in the driving shaft 21, the bearing shaft 56 and the driving shaft 21 clearance fit, the lower end of the bearing shaft 56 passes outside the driving shaft 21, the driving shaft 21 end is provided with the first bevel gear 31, and the emulsifying shaft 56 is provided with the first bevel gear at one end. The second bevel gear 32 driven by the first bevel gear 31, the other end of the emul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com