Low-temprature flue gas denitration and poisoning-prevention system

A low-temperature flue gas and denitrification technology, applied in the field of environmental protection and denitrification, can solve the problems of low-temperature catalysts being easily poisoned, achieve anti-poisoning ability, prolong service life, and solve the effects of being easily poisoned

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

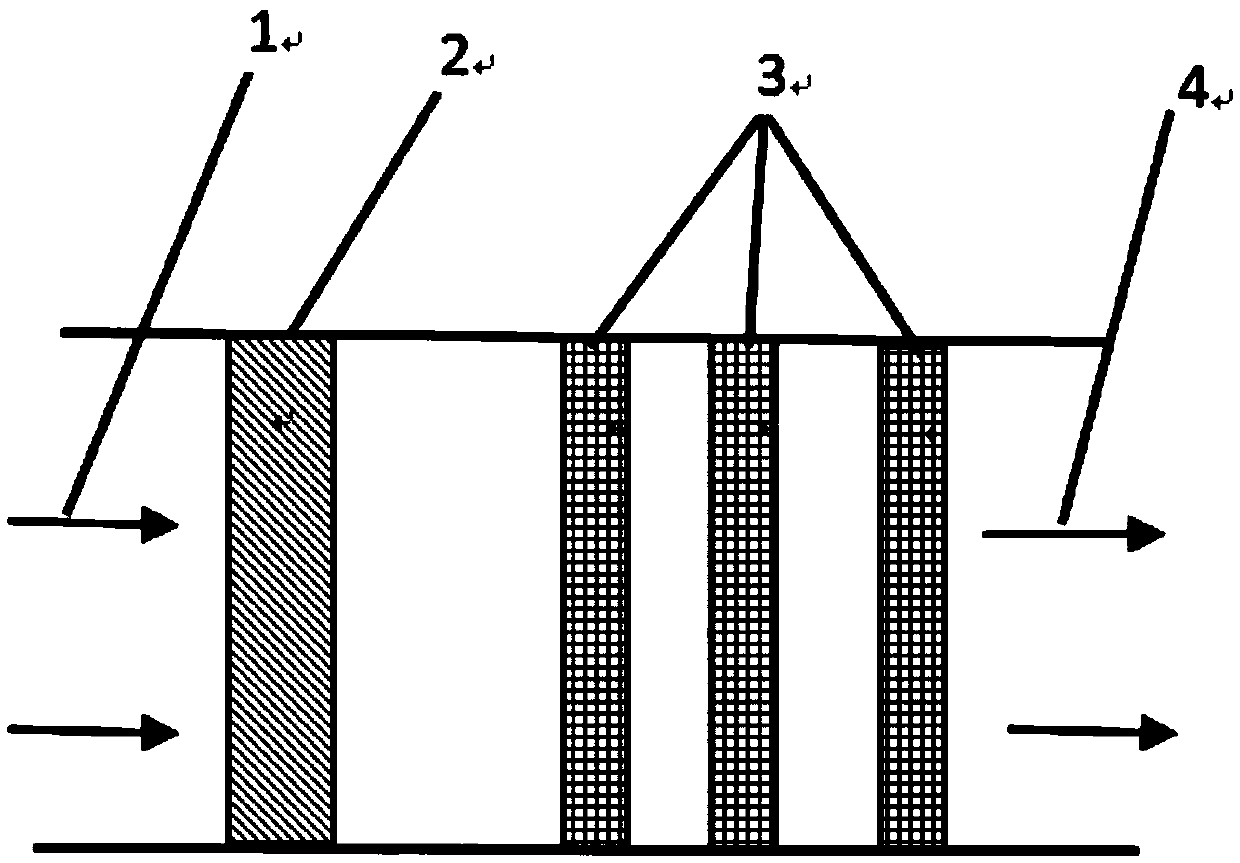

[0017] In an embodiment of the low-temperature flue gas denitrification anti-poisoning system provided by the present invention, in the SCR denitrification facility, a modified activated carbon layer 2 and a multi-layer denitrification catalyst 3 are arranged in sequence along the flow direction of the flue gas, and the modified activated carbon layer 2 passes physical Adsorption and chemical adsorption to adsorb water vapor and SO in flue gas 2 , heavy metals and dust, multi-layer denitrification catalyst 3 is used to remove NO in flue gas x ;By using modified activated carbon, SO can be removed more effectively 2 , dust, heavy metals and other pollutants, which greatly prolong the service life of the catalyst. The modified activated carbon does not reduce the temperature of the flue gas while removing the pollutants, which ensures the denitrificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com