Method for extracting tricin from corn bracts

A technology of alfalfa and corn, which is applied in the field of biomedicine, can solve the problems of low extraction efficiency of alfalfa, achieve the effects of increasing the burden of impurity removal, reducing impurity content, and shortening the extraction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

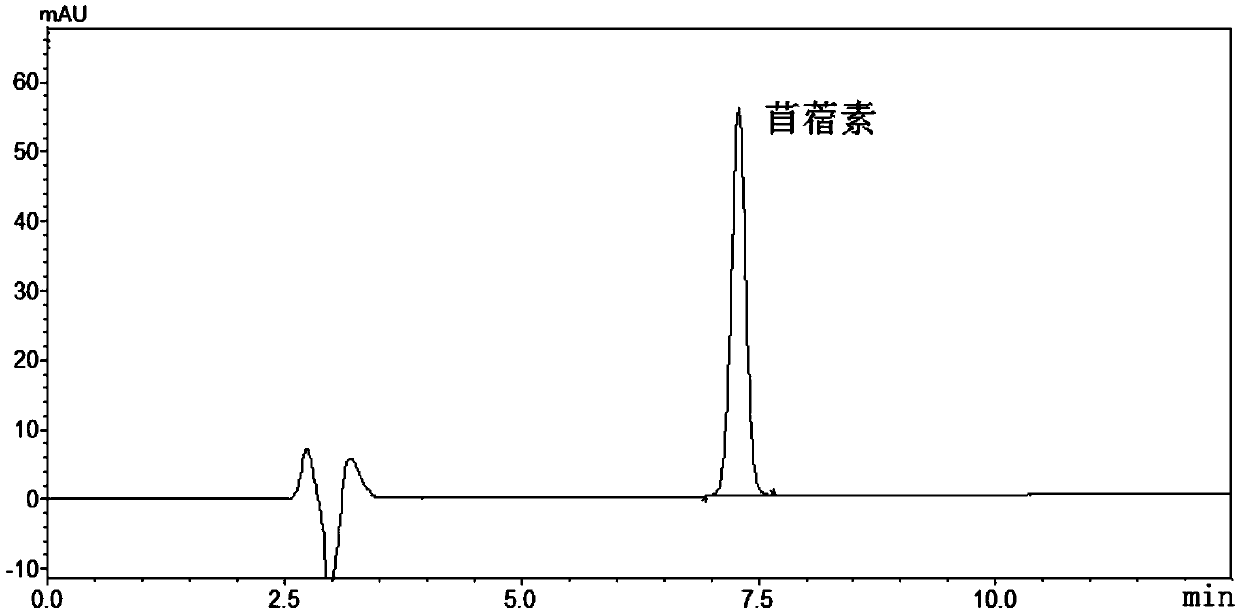

Embodiment 1

[0058] A method of extracting alfalfa from corn bracts in this embodiment comprises the following steps:

[0059] (1) Weigh 10 kg of dried corn bract pieces (particle size less than 0.5 cm), put them into a 200 L extraction tank, add 100 L of water, soak for 3 hours under stirring conditions, discard the extraction solution, and extract the slag for subsequent use;

[0060] (2) Extract the extraction slag with a volume fraction of 80% ethanol solution added with hydrochloric acid (12mol / L) to reflux, and concentrate the obtained extract under reduced pressure to obtain a concentrate; wherein, the amount of hydrochloric acid added is the corn bract 0.03% of crushed mass (ie 0.003kg);

[0061] Specifically: ① Add 100 L of ethanol solution with a volume fraction of 80% to the extraction residue, and start stirring;

[0062] ② Turn on the jacket steam, heat until ethanol reflux, start timing, and reflux extraction for 1 hour;

[0063] ③ After the reflux extraction is completed, ...

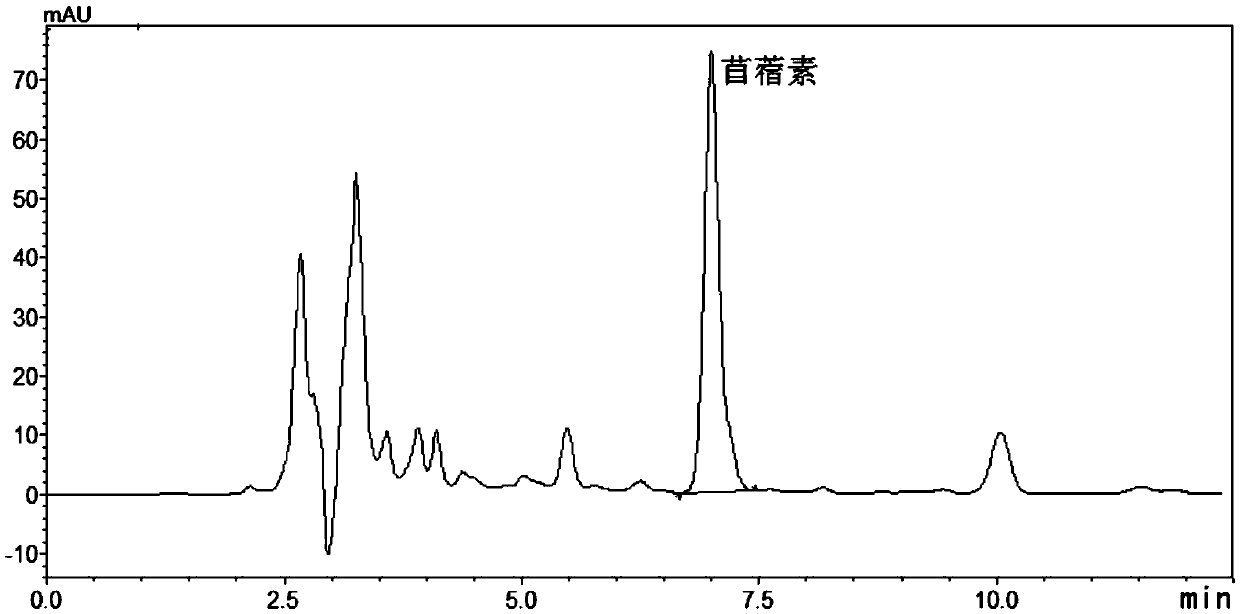

Embodiment 2

[0081] A method of extracting alfalfa from corn bracts in this embodiment comprises the following steps:

[0082] (1) Weigh 300 kg of dried corn bract pieces (particle size less than 0.5 cm), put them into a 3000L extraction tank, add 2400L of water, soak for 3h under stirring conditions, discard the extract, and extract the slag for subsequent use;

[0083] (2) Extract the extraction slag with a volume fraction of 85% ethanol solution added with hydrochloric acid (12mol / L) to reflux, and concentrate the resulting extract under reduced pressure to obtain a concentrate; wherein the amount of hydrochloric acid added is corn bract 0.03% of crushed mass (ie 0.09kg);

[0084] Specifically: ①Add 2400L of ethanol solution with a volume fraction of 85% to the extraction residue, and start stirring;

[0085] ② Turn on the jacket steam, heat until ethanol reflux, start timing, and reflux extraction for 1 hour;

[0086] ③ After the reflux extraction is completed, the feed liquid is pas...

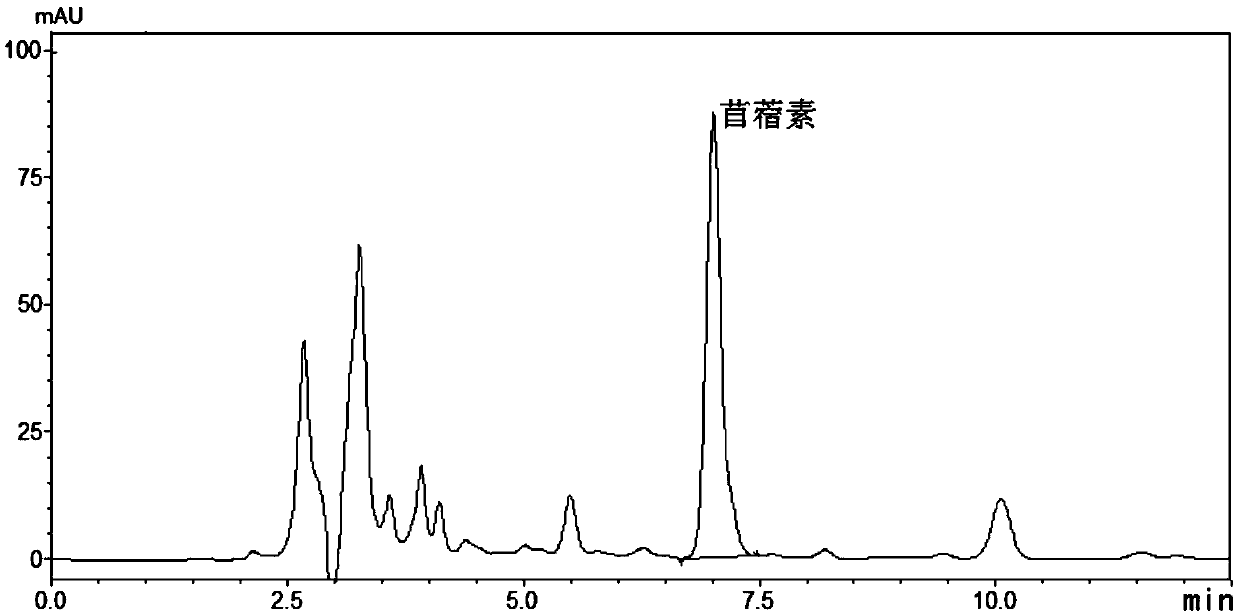

Embodiment 3

[0097] A method of extracting alfalfa from corn bracts in this embodiment comprises the following steps:

[0098](1) Weigh 200 kg of dried corn bract pieces (particle size less than 0.5 cm), put them into a 3000L extraction tank, add 2000L of water, soak for 3h under stirring conditions, discard the extract, and extract the slag for subsequent use;

[0099] (2) Extract the extraction slag with a volume fraction of 90% ethanol solution added with hydrochloric acid (12mol / L) to reflux, and concentrate the resulting extract under reduced pressure to obtain a concentrate; wherein the amount of hydrochloric acid added is corn bract 0.03% of crushed mass (ie 0.06kg);

[0100] Specifically: ①Add 2000L of the above-mentioned ethanol solution to the extraction residue, and start stirring;

[0101] ② Turn on the jacket steam and heat until ethanol refluxes, start timing, and reflux for 2 hours;

[0102] ③After the reflux extraction is completed, pass the feed liquid through a 400-mesh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com