Drilling slurry additive

A drilling mud and additive technology, which is applied to drilling compositions, chemical instruments and methods, etc., can solve the problems of viscosity deterioration, inability to obtain performance, and fluidity decline, and achieve high heat resistance and mechanical shear resistance. Low environmental adverse effects and high pseudoplastic fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

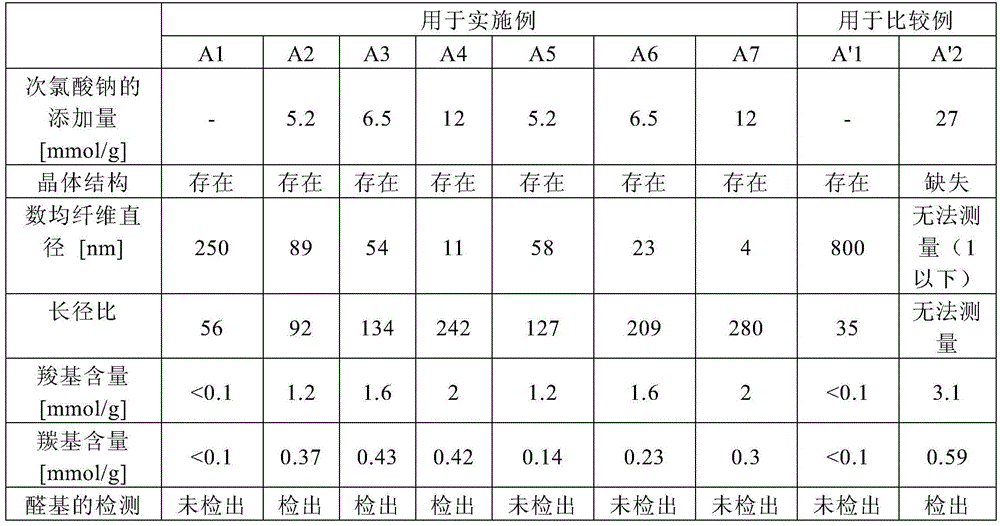

[0073] Next, Examples and Comparative Examples are described. However, the present invention is not limited to these Examples. "%" in the examples means % based on mass unless otherwise specified.

[0074] [production of cellulose fiber]

[0075] [Manufacture of Cellulose Fiber A1 (used in Examples)]

[0076] 50 g of bleached softwood kraft pulp (NBKP) was dispersed in 4950 g of water to prepare a dispersion having a pulp concentration of 1% by mass. The dispersion was treated 30 times with Cerendipiter MKCA6-3 (manufactured by Masuko Sangyo Co., Ltd.) to obtain cellulose fibers A1.

[0077] [Manufacture of Cellulose Fiber A2 (used in Examples)]

[0078] Add 150ml of water, 0.25g of sodium bromide and 0.025g of TEMPO to 2g of softwood pulp, fully stir and disperse, then add 13wt% sodium hypochlorite aqueous solution (co-oxidant) wherein, make the amount of sodium hypochlorite be 5.2mmol with respect to 1.0g pulp / g to initiate the reaction. Since the pH decreased as the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com