Plasma water preparation method and preparation device for speculum sterilization

A plasma and preparation device technology, applied in the field of plasma, can solve the problems of sterilizing device damage, high energy consumption, uneven discharge of the device, etc., and achieve the effect of reasonable design, simple preparation and high disinfection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

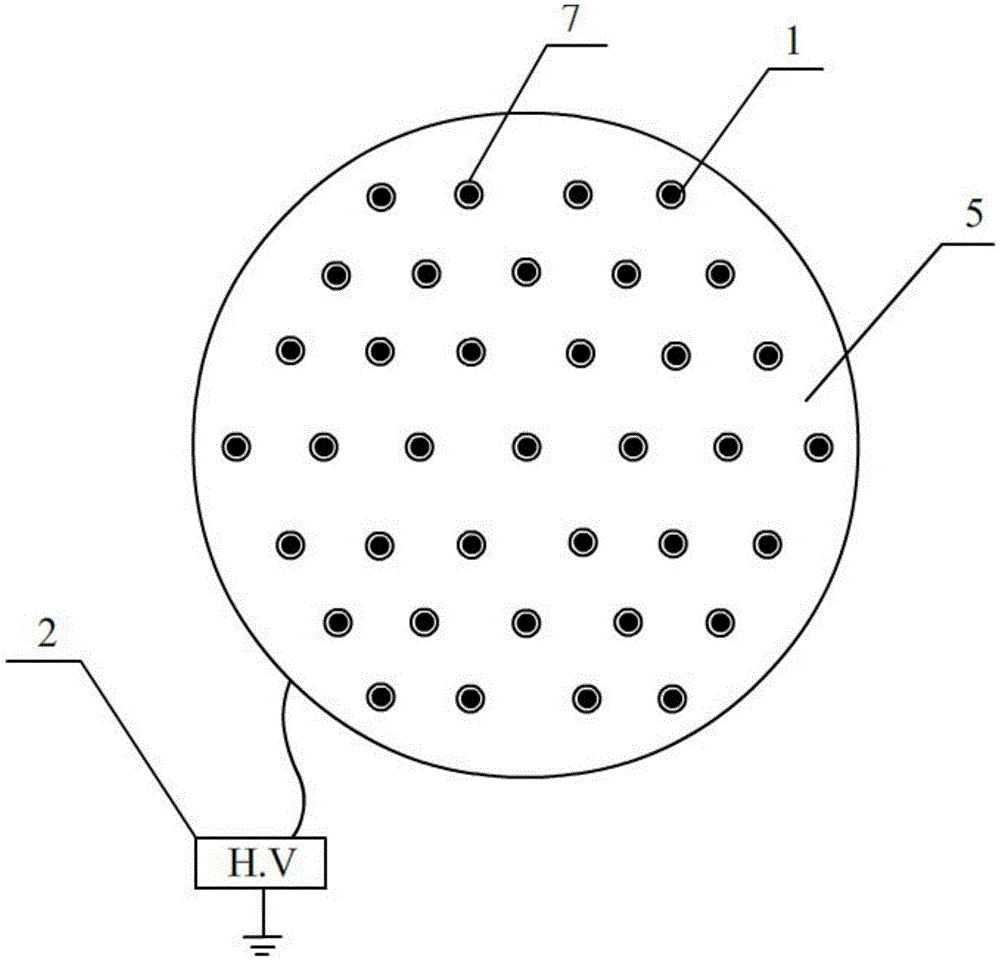

[0032] A conductive metal plate made of stainless steel is selected as the ground electrode, the thickness of the ground electrode is 5mm, and the diameter is 10cm. The outer diameter of the selected container is 15cm, the inner diameter is 14.8cm, and the capacity is 1L.

[0033] The thickness of the PCB board is 5mm and the diameter is 12cm.

[0034] A tipped tungsten rod with a diameter of 1.0 mm and a length of 6.5 cm was selected as the high-voltage electrode.

[0035] The insulating dielectric tube is made of quartz material, the length of the insulating dielectric tube is 4.5cm, the outer diameter is 3.0mm, the inner diameter is 1.5mm, and the tube wall thickness is 1.5mm. The distance between the centers of the high-voltage electrodes is 1.0 cm.

[0036] The AC power is selected as the power source, the discharge voltage of the AC power is 20kV, and the discharge rate is 7kHz.

[0037] A speculum with a length of 30 cm and an outer diameter of 5 mm was selected to v...

Embodiment 2

[0040] A conductive metal plate made of stainless steel is used as the ground electrode, the thickness of the conductive metal plate is 5 mm, and the diameter is 10 cm.

[0041] The outer diameter of the selected container is 17cm, the inner diameter is 16.8cm, and the capacity is 1L.

[0042] The thickness of the PCB board is 5mm and the diameter is 12cm.

[0043] A copper rod with a tip with a diameter of 1.5 mm and a length of 7.5 cm was selected as the high voltage electrode.

[0044] The insulating dielectric tube is made of quartz material, the length of the insulating dielectric tube is 5.5cm, the outer diameter is 3.0mm, the inner diameter is 1.5mm, and the tube wall thickness is 1.5mm. The distance between the centers of the high-voltage electrodes is 1.0 cm.

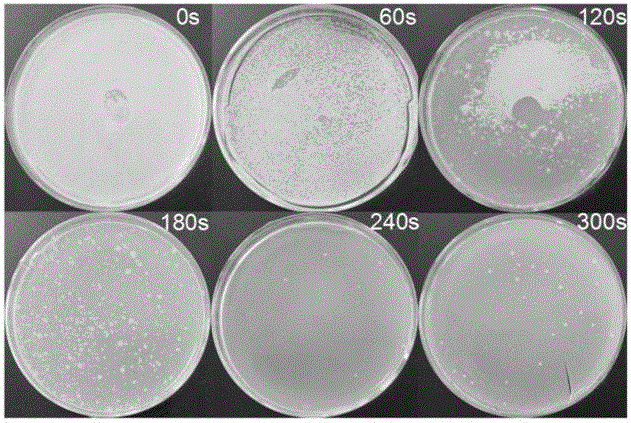

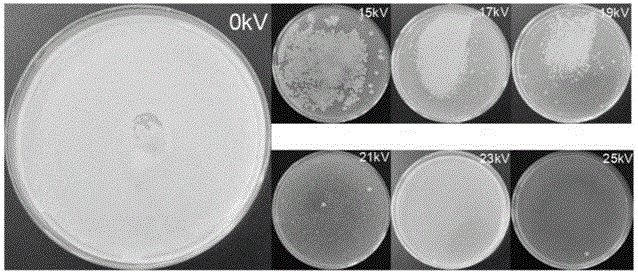

[0045] The AC power is selected as the power source, the discharge voltage of the AC power is 15-25KV, and the discharge rate is 5kHz.

[0046] A speculum with a length of 30 cm and an outer diameter of 5 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com