Nickel-cobalt-aluminum ternary cathode material with high tap-density and preparation method of nickel-cobalt-aluminum ternary cathode material

A technology of positive electrode material and tap density, which is applied in the field of nickel-cobalt-aluminum ternary positive electrode material with high tap density and its preparation, can solve problems such as unfavorable industrial production, non-continuous operation, cumbersome steps, etc., and achieve product consistency Good, reduce ion mixing, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

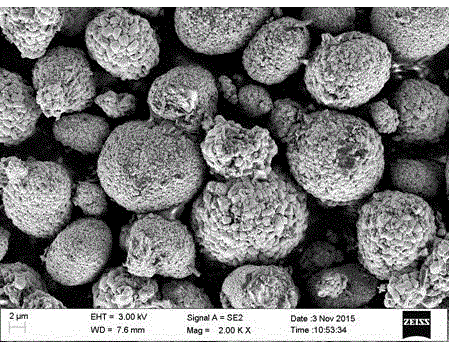

[0026] First, prepare a 1.5mol / L nickel-cobalt mixed solution with nickel nitrate and cobalt nitrate, wherein the molar ratio of nickel and cobalt is 0.86:0.14, prepare 3.0mol / L sodium hydroxide solution and 2.0mol / L ammonia solution, Add the above three solutions into the reaction kettle concurrently, adjust by the online pH automatic control system, control the pH value in the reaction kettle to 11.2, temperature 50°C, ammonia concentration 5g / L, stirring speed 700rpm, co-precipitation reaction, overflow discharge. The slurry is washed until the pH is less than 8.0, dried at 150° C., and sieved to obtain spherical nickel-cobalt precursor powder.

[0027] Secondly, the above-mentioned nickel-cobalt precursor, aluminum oxide, magnesium hydroxide, and lithium hydroxide are mixed uniformly according to the molar ratio of metal ions of 0.93:0.07:0.003:1.03, and placed in an oxygen-enriched atmosphere (oxygen mass fraction greater than 95%) at 450°C Pre-fired for 6 hours, then dir...

Embodiment 2

[0030] First, prepare a 1.0mol / L nickel-cobalt mixed solution with nickel chloride and cobalt sulfate, in which the molar ratio of nickel and cobalt is 0.867:0.133, prepare 1.0mol / L sodium carbonate solution, 0.5mol / L EDTA and ammonia water Mix the solution (where EDTA is 0.3mol / L, and ammonia water is 0.2mol / L), add the above three solutions into the reactor in parallel, and adjust it by the online pH automatic control system to control the pH value in the reactor to 8.1 and the temperature to 25°C , complexing agent concentration 2g / L, stirring speed 500rpm, co-precipitation reaction, overflow discharge. The slurry is washed until the pH is less than 8.0, dried at 150° C., and sieved to obtain spherical nickel-cobalt precursor powder.

[0031] Secondly, the above-mentioned nickel-cobalt precursor, aluminum nitrate, and lithium carbonate were mixed uniformly according to the metal ion molar ratio of 0.98:0.02:1.06, and pre-fired in an oxygen-enriched atmosphere (oxygen mass f...

Embodiment 3

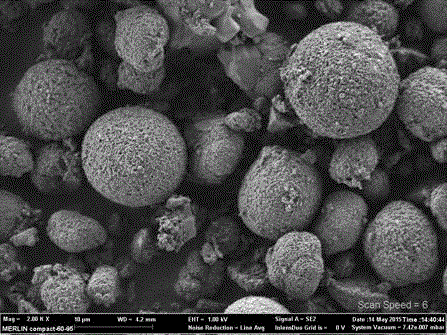

[0033] First, prepare a 2.0mol / L nickel-cobalt mixed solution with nickel acetate and cobalt acetate, wherein the molar ratio of nickel and cobalt is 0.778:0.222, prepare 8.0mol / L sodium hydroxide solution and 10.0mol / L ammonia solution, The above three solutions were added into the reaction kettle in parallel, and adjusted by the online pH automatic control system to control the pH value in the reaction kettle to 12.0, the temperature to 60°C, the concentration of ammonia water to 13g / L, and the stirring speed to 800rpm. Co-precipitation reaction, overflow discharge. The slurry is washed until the pH is less than 8.0, dried at 120° C., and sieved to obtain spherical nickel-cobalt precursor powder.

[0034]Secondly, the above-mentioned nickel-cobalt precursor, aluminum hydroxide, copper nitrate, and lithium acetate were mixed uniformly according to the metal ion molar ratio of 0.90:0.10:0.005:1.09, and preheated in an oxygen-enriched atmosphere (oxygen mass fraction greater tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com