A rubber ball cleaning system

A cleaning system and technology for rubber balls, applied in the field of rubber ball cleaning systems, can solve the problems of low ball collection rate, staying in, and high equipment failure rate, and achieve the effects of uniform cleaning effect, long rubber ball life and high operating efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Specific embodiments of the present invention will be described in detail below.

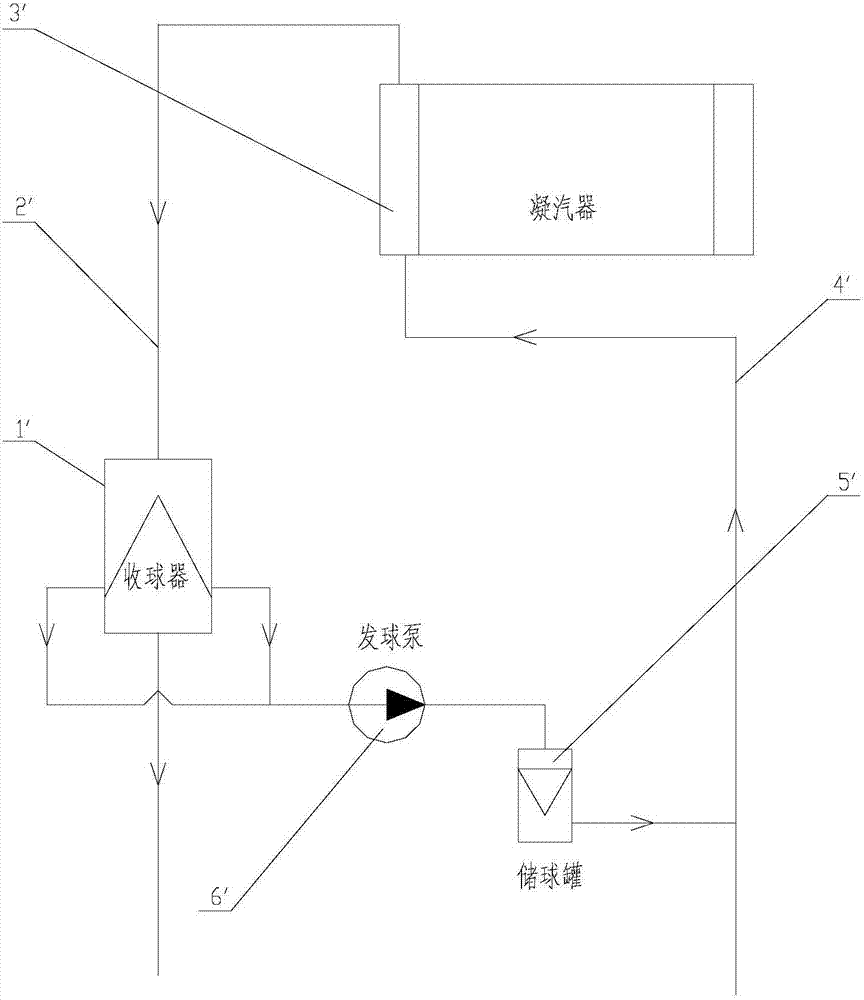

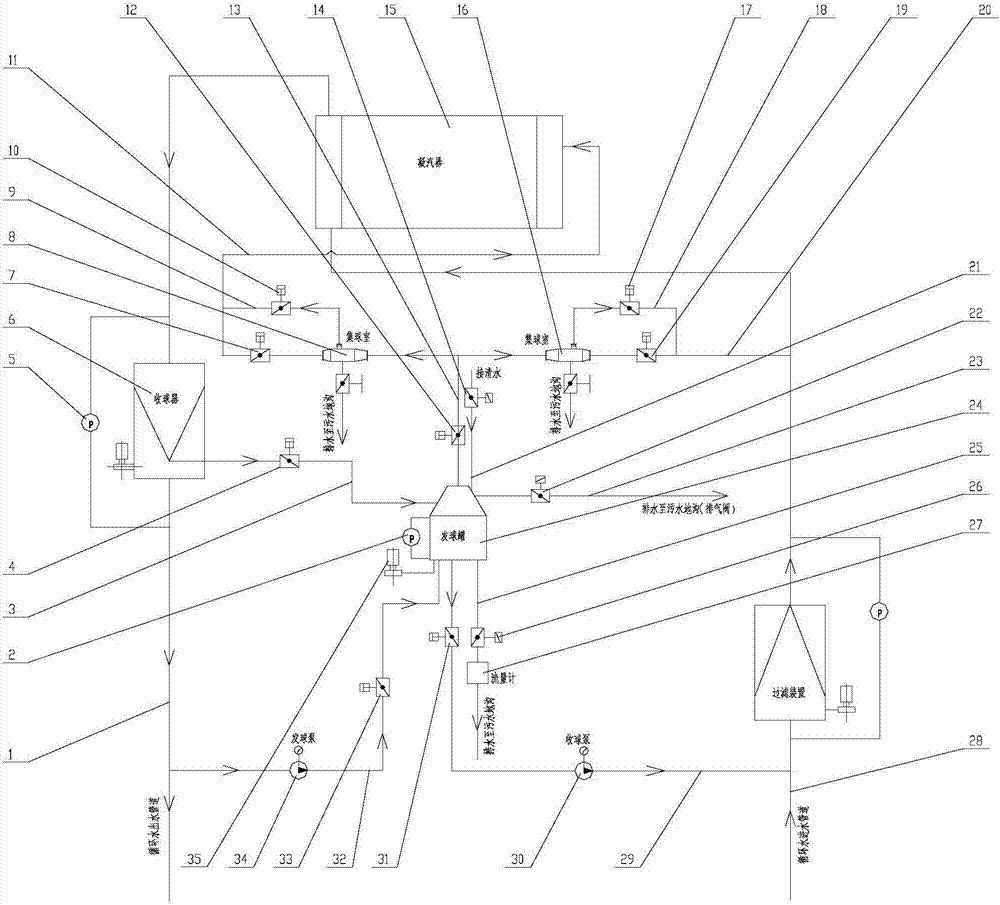

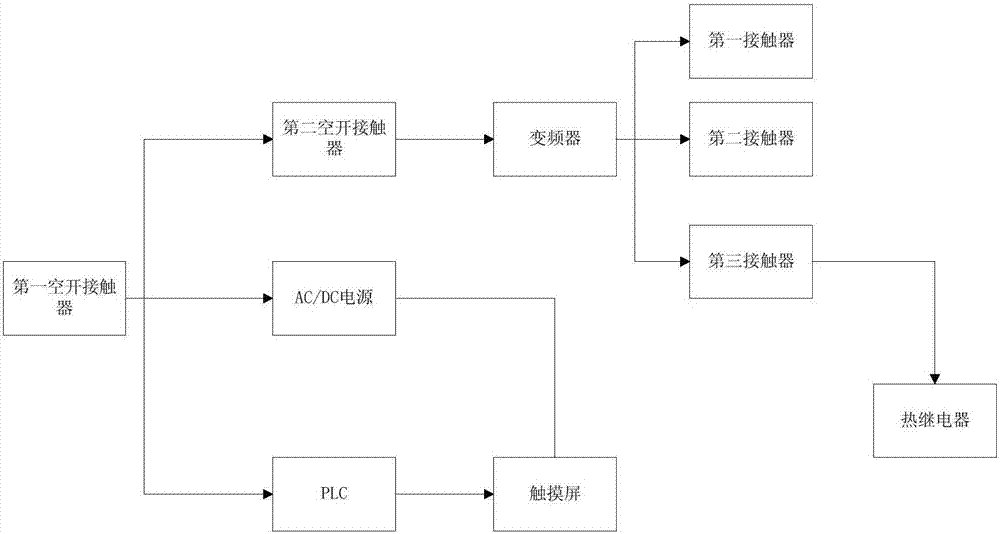

[0065] Such as Figure 1~3 Shown, a kind of rubber ball cleaning system comprises ball collecting device 6, ball sending device 24, second ball collecting device 8 and first ball collecting device 16 and controller,

[0066] The ball server 24 is connected to the ball outlet of the ball collector 6 through the ball collection pipeline 3, and the ball collection valve 4 is arranged in the ball collection pipeline 3,

[0067] The ball server 24 is respectively connected to the first ball collector 16 and the second ball collector 8 through the third ball collector 13, and the third ball collector 13 is provided with a third ball collector 12,

[0068] The ball server 24 is connected to the ball pump 34 through the second water outlet pipeline 32, the second water outlet pipeline 32 is provided with a water outlet valve 33, and the ball server pump 34 is externally connected to the circulat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com