A Hazardous Chemical Incinerator Assisted by Electromagnetic Induction

A technology of electromagnetic induction and hazardous chemicals, which is applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of high ratio of incineration and air intake, difficult to achieve, and blockage of burners, etc., to improve incineration Effect of increasing temperature, increasing reaction rate, and preventing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and examples, and the contents of the examples are not intended to limit the protection scope of the present invention.

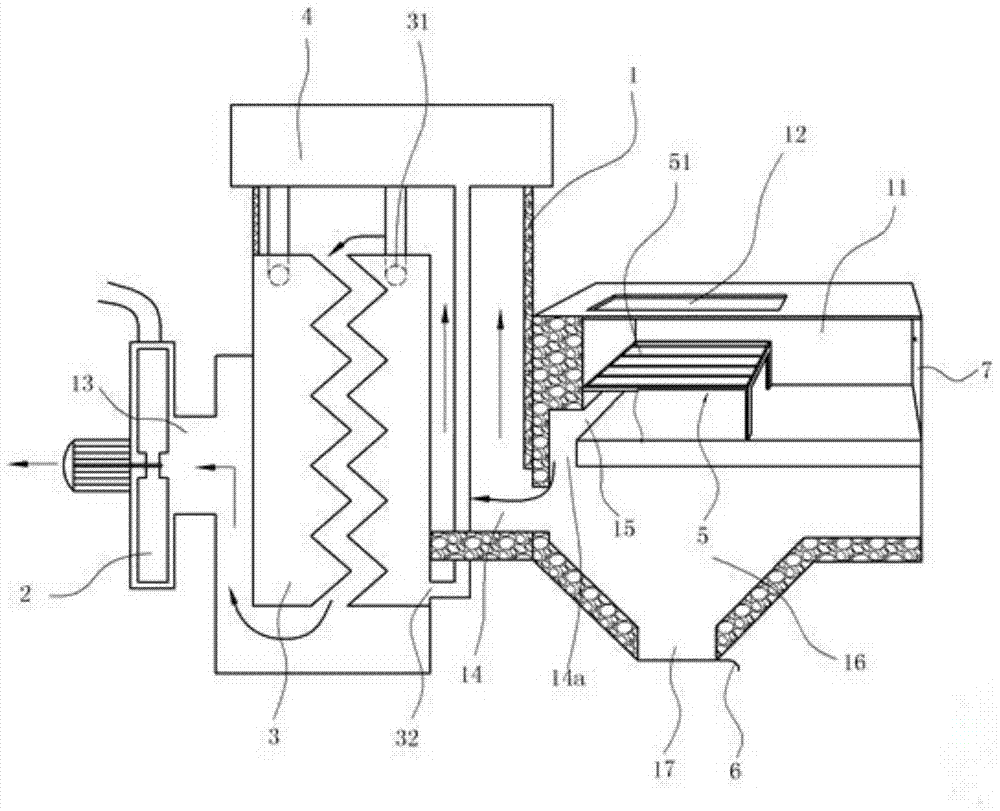

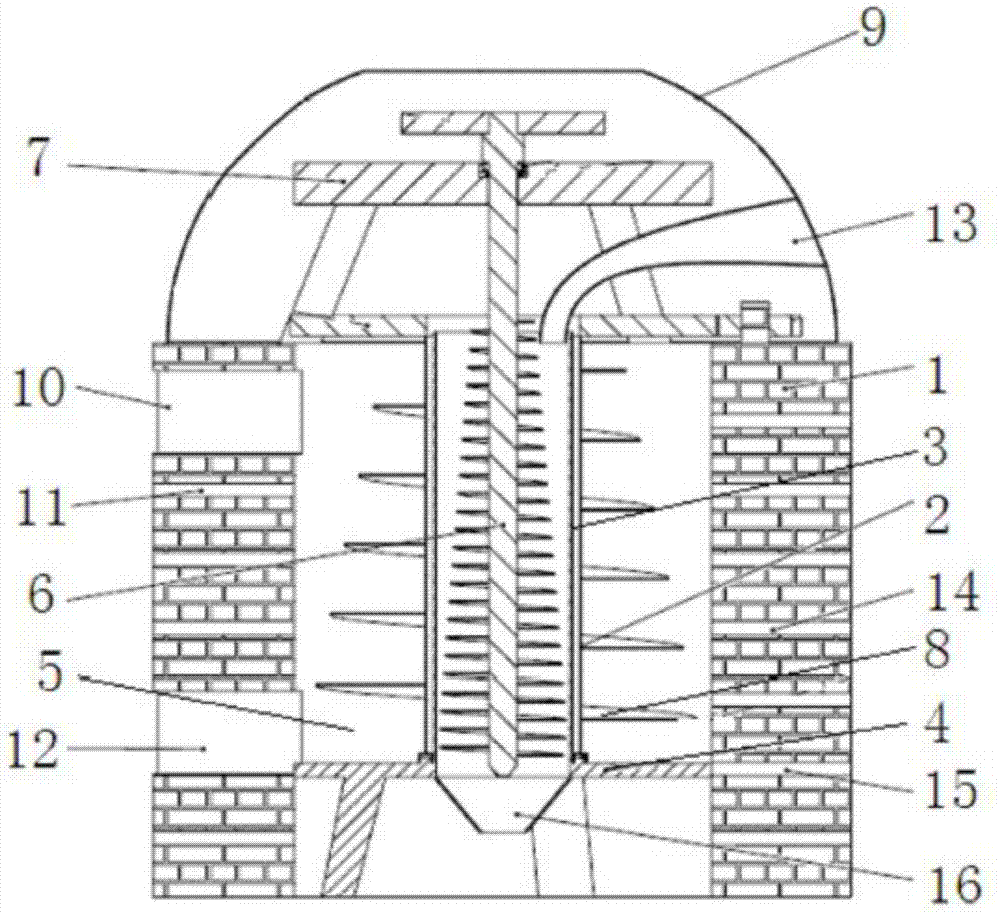

[0027] Figure 4 A schematic structural view of the electromagnetic induction assisted hazardous chemicals incinerator of the present invention is shown. like Figure 4 As shown, the electromagnetic induction assisted hazardous chemicals incinerator of the present invention includes a furnace body 1 and a radiation-proof alloy protective layer 13 located outside the furnace body 1 . A stove 2 is arranged in the lower part of the furnace body 1 . The furnace body 1 is a sealed cavity filled with porous materials. There is a catalyst on the surface of the porous material, so that under the action of the catalyst, the waste can be completely incinerated and the reaction rate can be increased. The anti-radiation alloy protective layer 13 can effectivel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com