Boiler water circulation device with middle mixing headers and pressure balance pipes

A technology of mixing headers and balance tubes, applied in boiler water pipes, steam boilers, steam boiler accessories, etc., can solve problems such as excessive temperature deviation of outlet steam, low mass flow rate, and uneven distribution of pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The content of the present invention will be described in further detail below in conjunction with the accompanying drawings.

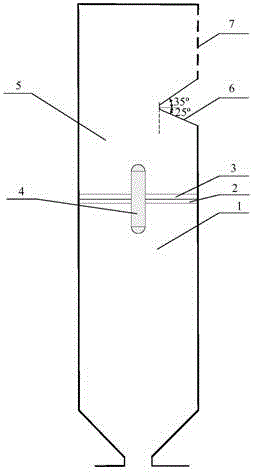

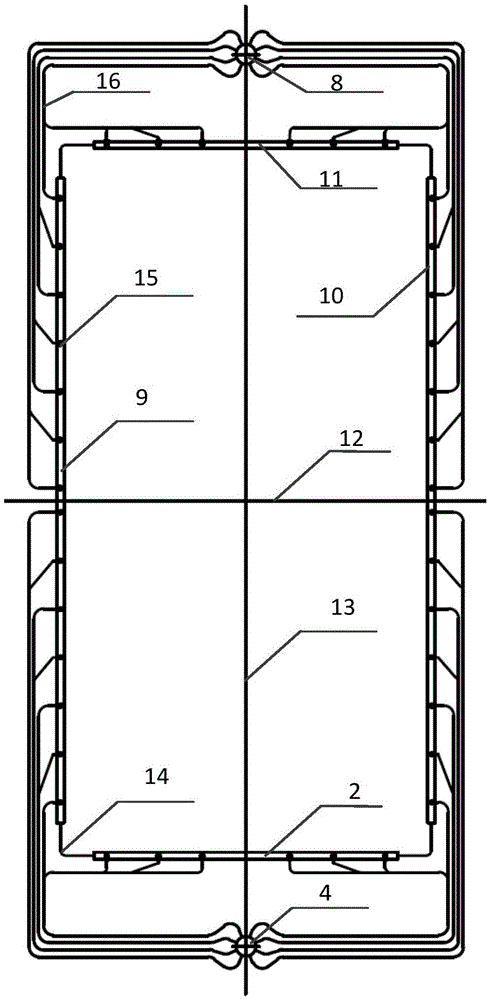

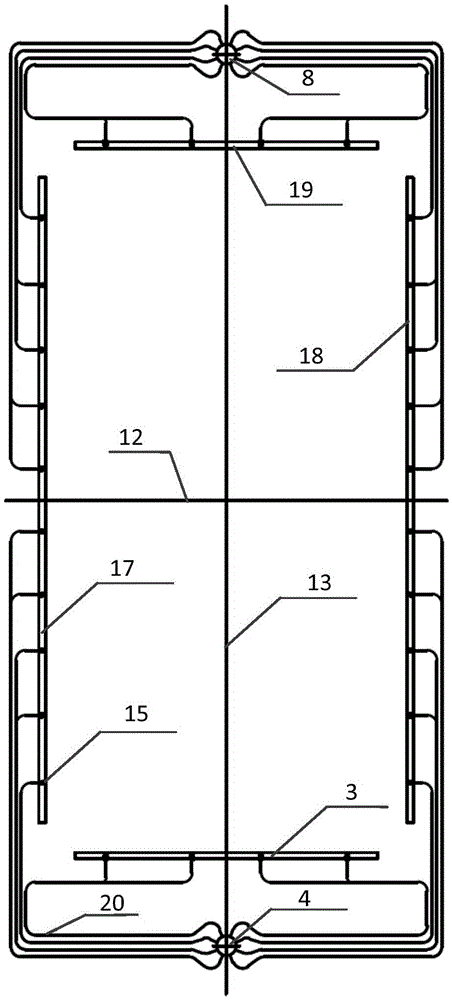

[0016] refer to figure 1 , 2 As shown in , 3, a medium mass flow rate ultra-supercritical boiler water circulation device is composed of an upper and lower furnace, and the water wall 1 of the lower furnace adopts a high-ribbed optimized internal thread pipe, and the structure is a vertical pipe ring, and the water wall 5 of the upper furnace adopts a smooth tube , the structure is a vertical pipe ring, after the working medium passes through the vertical water wall 1 on the front, rear, left and right walls of the lower furnace, it enters the horizontal confluence intermediate header 9 on the front wall of the lower furnace, the horizontal confluence intermediate header 10 on the rear wall of the lower furnace, and the lower furnace The middle confluence header 2 is placed horizontally on the right side wall and the confluence middle header 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com