Pumping reversing control method

A control method and pumping technology, applied in servo motors, mechanical equipment, fluid pressure actuating devices, etc., can solve the problems of load and flow gears, low reliability and inability to adapt to changes, etc., to achieve high reliability, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

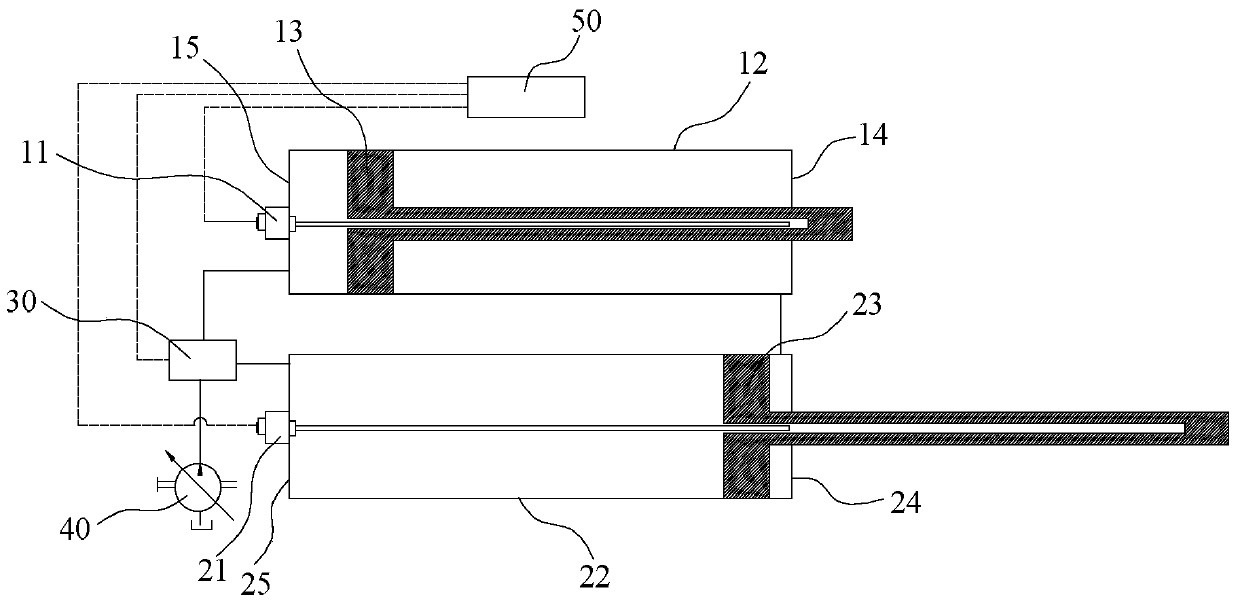

Examples

Embodiment 2

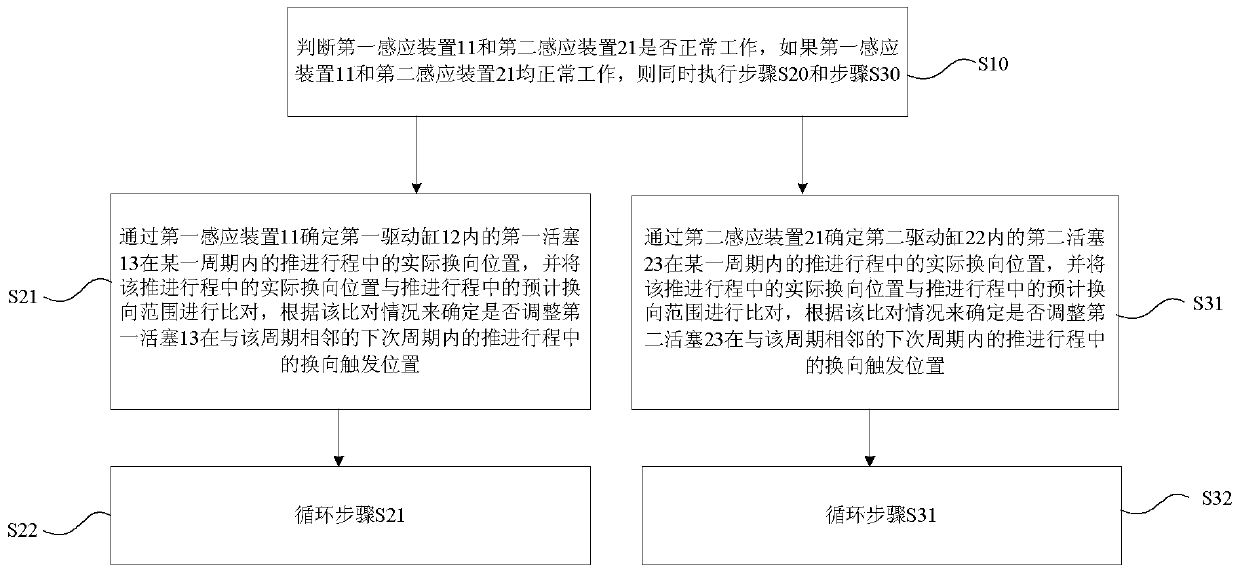

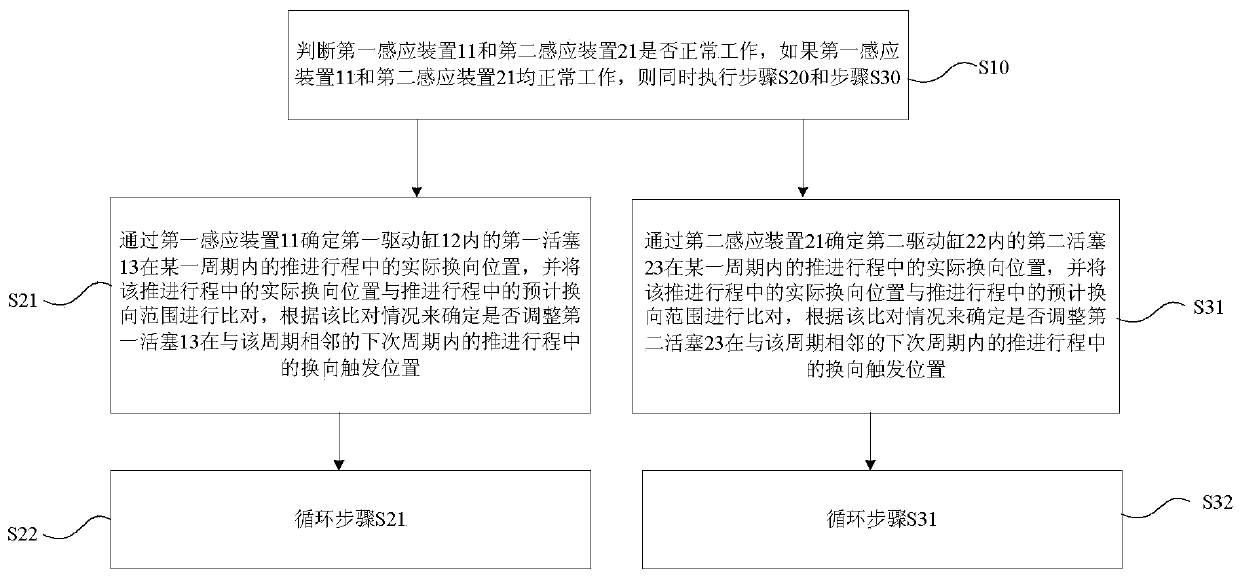

[0045] The pumping reversing control method of Embodiment 2 is also applied to the pumping device applied by the pumping reversing control method of Embodiment 1. The pumping reversing control method of Embodiment 2 includes Step S20 and Step S30, wherein the step S20 comprises step S21 and step S22, and step S30 comprises step S31 and step S32, and above-mentioned each step is as follows:

[0046] Step S21: Determine the actual reversing position of the first piston 13 in the first driving cylinder 12 in the retraction stroke within a certain cycle through the first sensing device 11, and compare the actual reversing position in the retraction stroke with The expected reversing range in the retraction stroke is compared, and it is determined whether to adjust the reversing trigger position of the first piston 13 in the retracting stroke in the adjacent next cycle according to the comparison. Step S22: loop through step S21.

[0047] Step S31: Determine the actual reversing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com