Chute section

A technology of chute section and section, applied in the field of chute section, can solve the problems of crack formation, defects, high processing cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

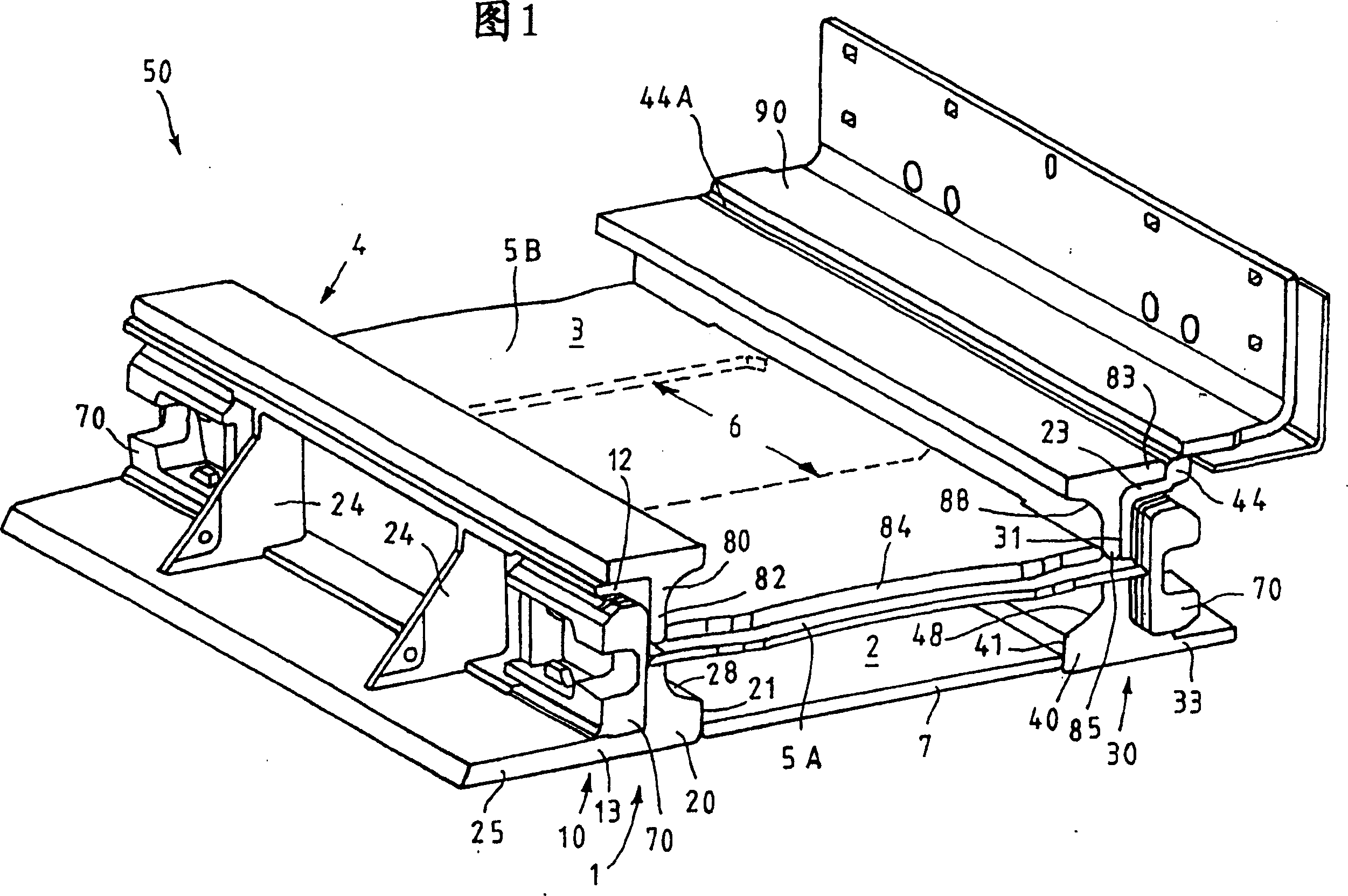

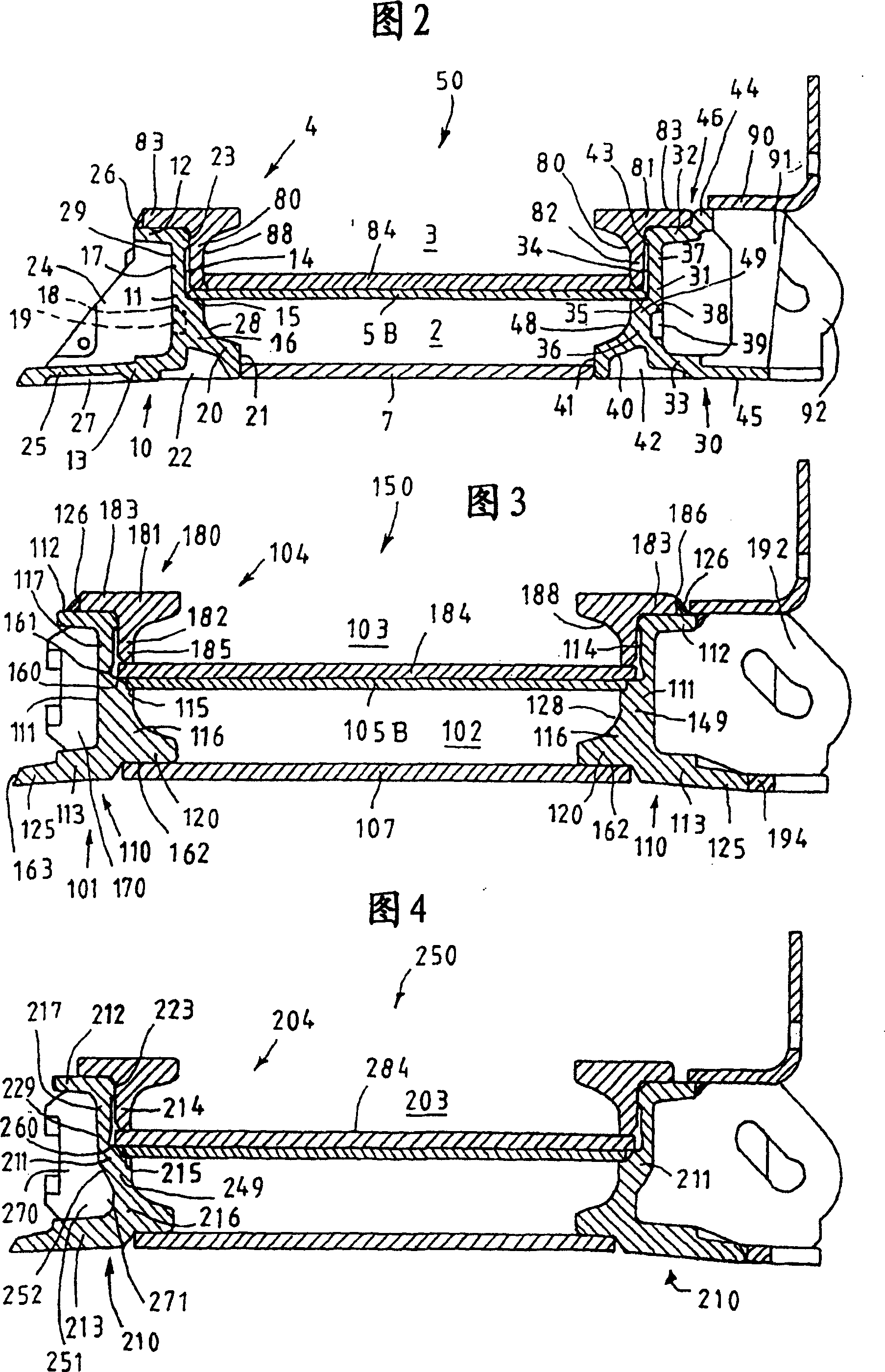

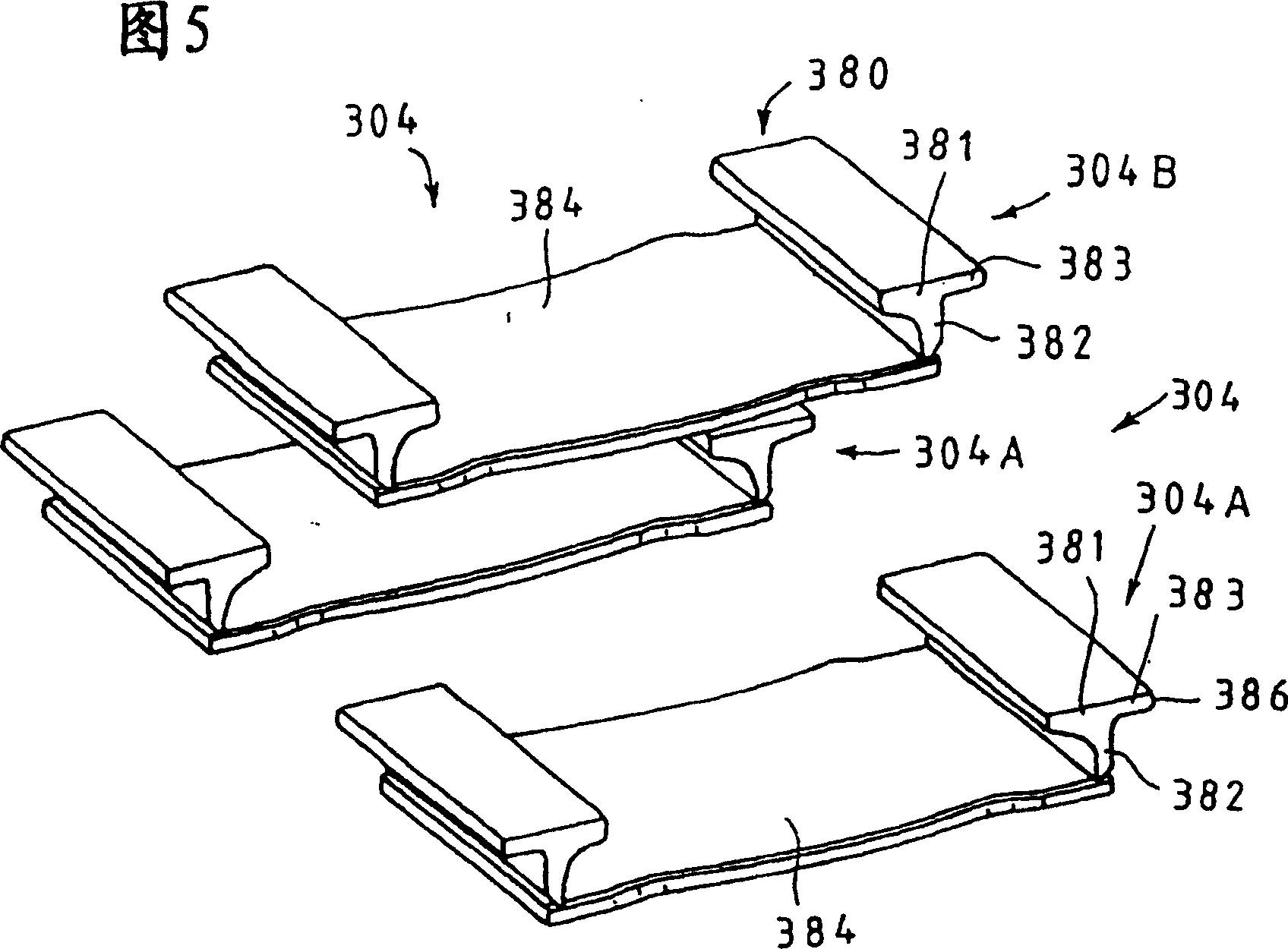

[0023] The chute section generally indicated by 50 in FIGS. 1 and 2 is an embodiment of a conveyor for underground longwall faces, which comprises a frame structure 1 directly forming the boundary of the lower working section 2 and a A replaceable or wearable groove 4 that constitutes the upper working section 3 is designed to be replaceable and bears on the frame structure 1 . The replaceable tank 4 shown in the assembled state can be lifted vertically from the frame structure 1 . The frame structure 1 of the chute section 50 has two differently designed asymmetric side frames 10, 30 composed of castings as important components, wherein the side frame 10 is arranged on the front wall side of the working face in the long wall working face conveyor, And the side frame 30 is provided on the filling side. The two side frames 10, 30 respectively have an intermediate flange 11, 31, a flange extension 12, 32 that protrudes outwards at the top and is cast on the intermediate flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com