Equipment for preparing bamboo pulp

A bamboo pulp and equipment technology, applied in pulp dewatering, digester, textile and papermaking, etc., can solve the problems of clogging reaction, incompleteness, low yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

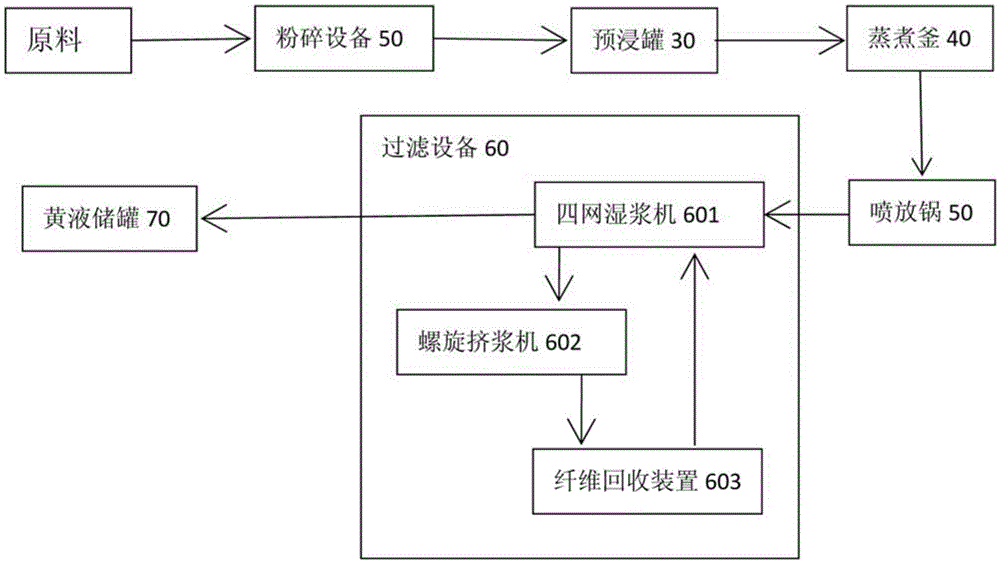

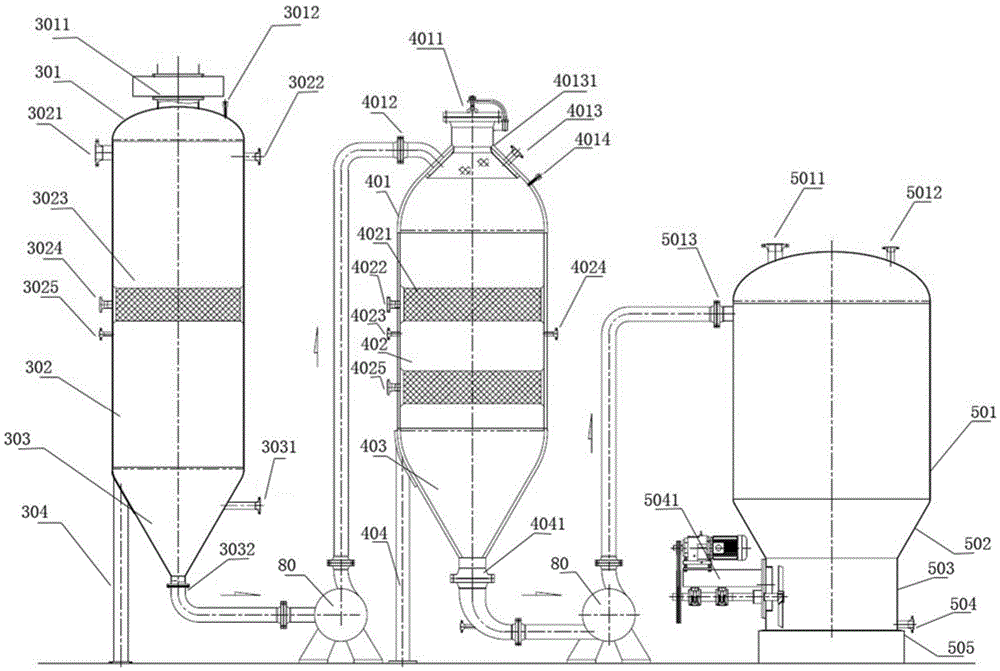

[0032] see Figure 1 to Figure 2 As shown, a line automatic pressure regulating device of the present invention includes: crushing equipment 20, prepreg tank 30, cooking kettle 40, spray pot 50, filtering equipment 60 and yellow liquid storage tank 70;

[0033] The pulverizing equipment 20 is used to pulverize the bamboo raw material; the prepreg tank 30 is used to soak the pulverized bamboo raw material in hot water to generate initial bamboo pulp; the cooking kettle 40 mixes the initial bamboo pulp with a catalyst, Carry out high-temperature and high-pressure cooking to obtain the reaction bamboo pulp, and spray it to the spray pot 50; after the spray pot 50 stirs the reaction bamboo pulp, the reaction bamboo pulp is separated from the solid and liquid by the filter device 60 to obtain yellow liquid and solid residue, the yellow liquid is stored in the yellow liquid storage tank 70 .

[0034] Furthermore, the temperature in the cooking kettle 40 is 160°~200°, especially at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com