Manufacturing method for furnace bottom roller

A manufacturing method and furnace bottom roller technology, which are applied in metal material coating process, coating and other directions, can solve the problems of high cost, impact on product quality and service life, roll ring accumulation, etc., so as to prolong service life and improve durability. Grinding, reducing the effect of accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

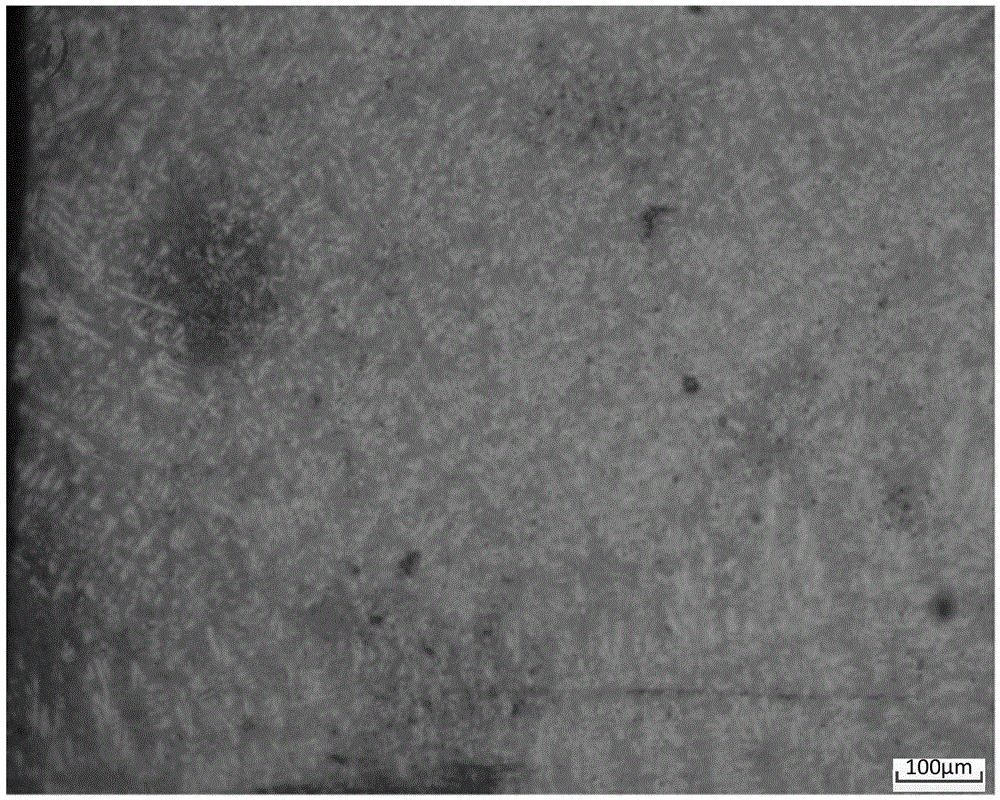

Image

Examples

Embodiment Construction

[0022] The embodiment of the present application provides a method for manufacturing hearth rolls, which solves the technical problem of the build-up of roll rings in the prior art, which affects product quality and service life, and the cost is relatively high.

[0023] The technical solution in the embodiment of the present application is to solve the technical problems in the prior art, and the general idea is as follows:

[0024] A method for manufacturing a hearth roll, the manufacturing method comprising: making a nickel-based roll ring and a roll core, fixing the nickel-based roll ring on the roll core to obtain a prefabricated hearth roll; cleaning the nickel-based roll The surface of the roll ring; obtaining a cladding powder comprising NiCr-Cr 3 C 2 , WC, TiN, rare earth, wherein, the NiCr-Cr 3 C 2 The mass percentage is 80% to 90%; the prefabricated hearth roll is fixed on the machine tool, and the surface of the nickel-based roll ring is laser clad by a laser we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com