A three-dimensional nano-pitch template and its preparation method

A three-dimensional nano-pitch technology, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of thick deposition lines, poor reproducibility, and strict environmental requirements, so as to meet the stability and uniformity and solve the problems. Uncontrollable problems, controllable process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and implementation example:

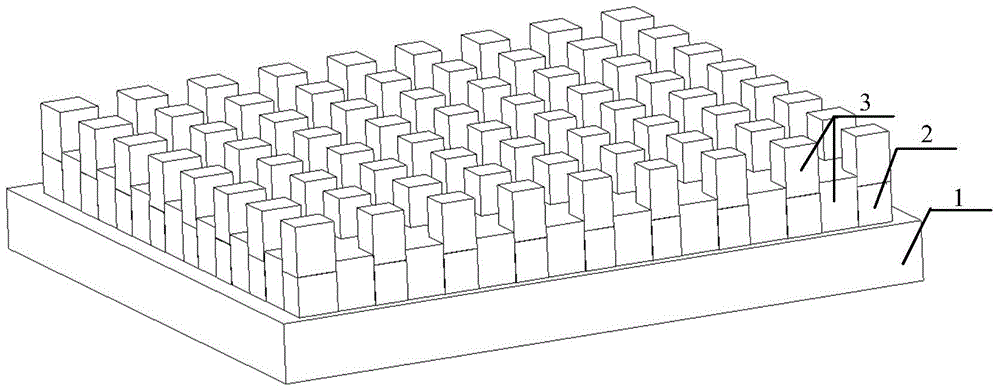

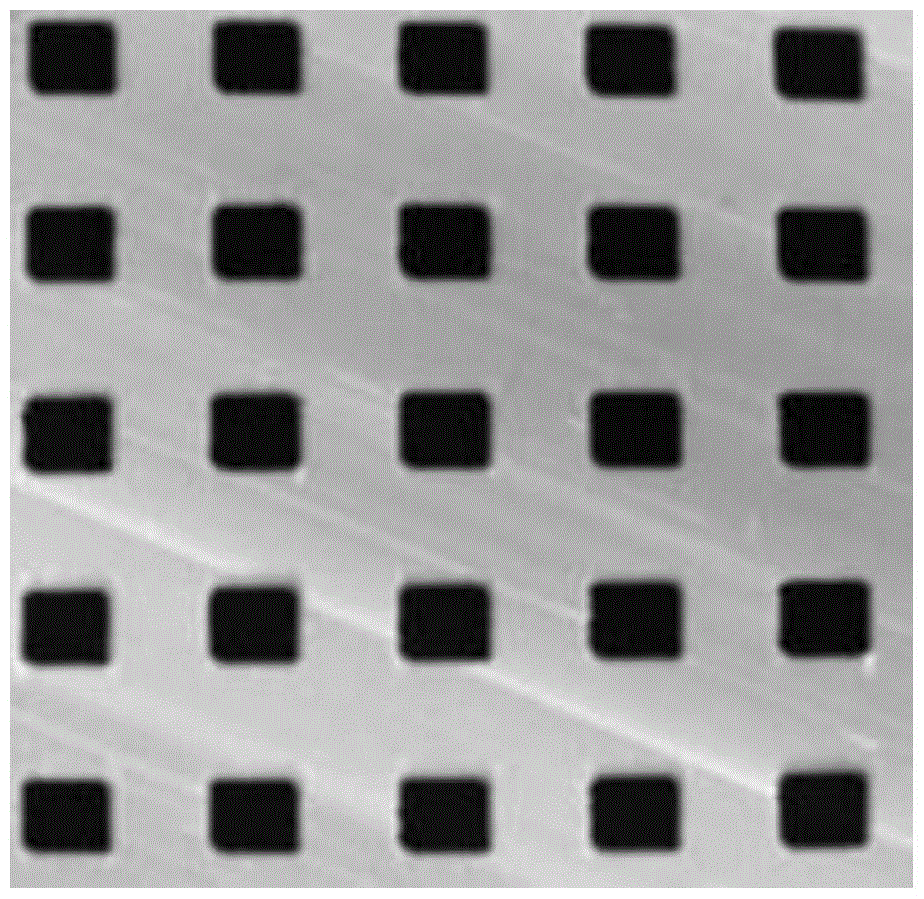

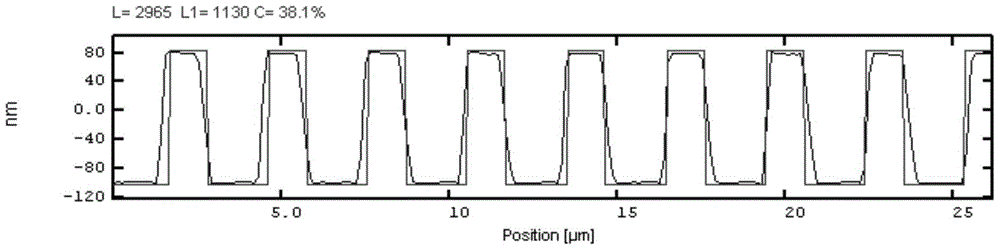

[0029] The three-dimensional nano-pitch model in this embodiment has a structure such as figure 1 As shown, it includes: a substrate 1 , a first epitaxial film layer 2 and a second epitaxial film layer 3 . The composition relationship is as follows: using molecular beam epitaxy technology to realize the growth of the first epitaxial film layer 2 on the substrate 1; then using etching technology to transfer the pitch mask structure to the first epitaxial film layer 2; and then using molecular beam epitaxy Technology The second epitaxial film layer 3 is grown on the first epitaxial film layer 2 . During the growth process of the first epitaxial film layer 2 and the second epitaxial film layer 3 , film-forming atoms grow in a layered structure mode. Since the film-forming atoms grow according to the layered structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com