Antifouling composite membrane and antifouling panel containing composite membrane as well as preparation method of composite membrane

A composite film and board technology, applied in chemical instruments and methods, synthetic resin layered products, lamination, etc., can solve the problems of poor pattern richness and poor pollution resistance, and achieve good adhesion, good stain resistance, and visual good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

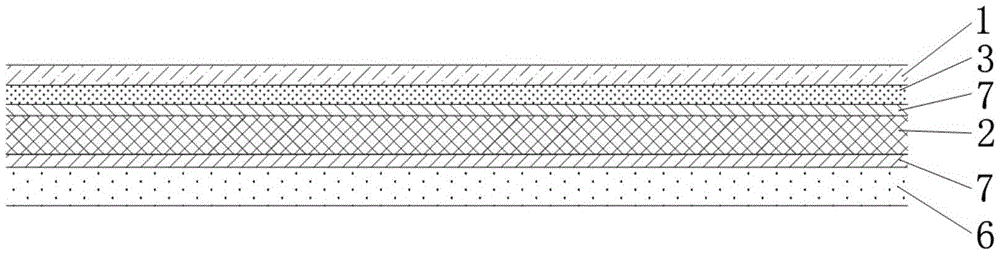

[0046] Such as figure 2 As shown, on the basis of the prior art, a UV layer is added to the original outermost PET plastic layer 1. Although the effect is better than that in the prior art, it cannot solve the problem in the prior art. The problem.

Embodiment 2

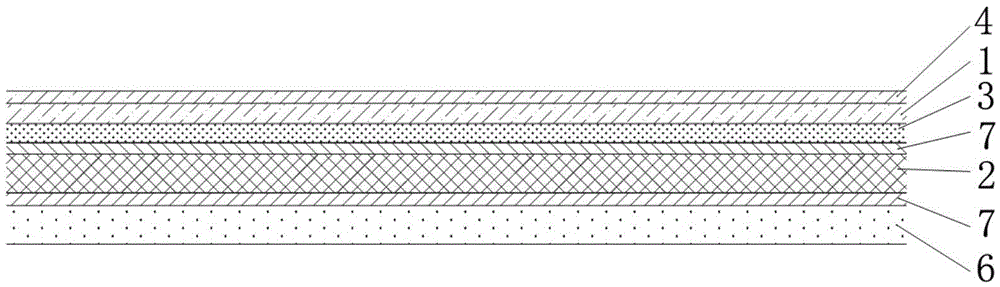

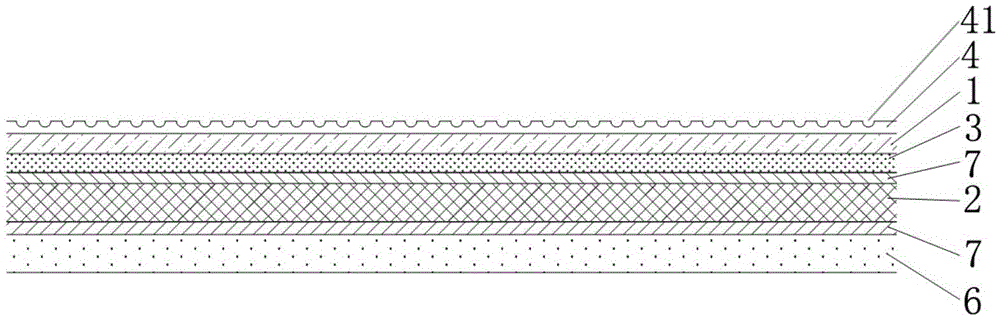

[0048] Such as image 3 As shown, this embodiment is a more preferred technical solution. The antifouling composite film includes a PET plastic layer 1 and a PVC plastic layer 2. A printed pattern layer 3 is provided on one side of the PET plastic layer 1, and the PET plastic layer 1 The side with the printed pattern layer 3 is attached to the PVC plastic layer 2, the other side of the PET plastic layer 1 is covered with a UV layer 4, and a geometric pattern is provided on the surface of the UV layer 4 41. At this time, the outermost layer of the anti-fouling composite film is the geometric pattern 41 on the surface of the UV layer 4, which can not only display a variety of colors and patterns through the printed pattern layer 3 of the PET plastic layer 1, but also through engraving The UV layer 4 with geometric patterns 5 improves the surface contamination resistance.

[0049] The side of the PET plastic layer 1 with the printed pattern layer 3 and the PVC plastic layer 2 are b...

Embodiment 3

[0060] Such as Figure 4 As shown, this embodiment is on the basis of Example 2, and a metal layer 5 is also provided between the printed pattern layer 3 and the PVC plastic layer 2, which makes the printed pattern layer more metallic in appearance. Example 2 is better than the implementation Example 3 lacks the metal layer 5, and the metal texture of the anti-fouling composite film and the anti-fouling board is weak. Preferably, the metal layer 5 is aluminum foil or aluminum or zinc plating.

[0061] The preparation method of the anti-fouling board of embodiment 3 includes the following steps:

[0062] Step 1. Coat the UV layer 4 on one side surface of the PET plastic layer 1, and roll it on the surface of the UV layer 4 with a metal roller mold engraved with corresponding geometric figures. , Instantly solidify to form a geometric figure 41;

[0063] Step 2: Printing a specific pattern on the other side surface of the PET plastic layer 1 to form a printed pattern layer 3; a meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com