A pcb soldering device

A technology of welding device and discharging device, which is applied in the direction of electric heating device, tin feeding device, welding equipment, etc., can solve the problems of difficult control of operation standardization, and achieve the effect of operation standardization and easy control, shortening length and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

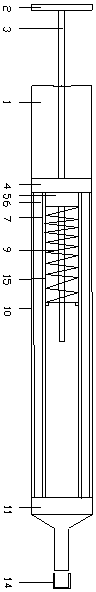

[0025] Such as figure 1 As shown, a pcb welding device includes a hollow tube 15, one end of the hollow tube 15 is sealed and connected with the discharge device 11, and the other end is sealed with the connection part 4, and the hollow tube 15 is connected with the discharge device 11 and the connection part 4 The sealing joints are all threaded connections, and the threaded connections are easy to disassemble. The discharge device 11 is funnel-shaped, and the tapered portion of the discharge device 11 is detachably provided with an end cap 14; the hollow tube 15 is provided with a piston 5, and a copper pipe 3 runs through the piston 5 along its axial direction. The copper tube 3 is connected to the piston in a sealed manner, the copper tube 3 passes through the connecting part 4, and can slide along the connecting part 4, the end of the copper tube 3 different from the piston 5 is provided with a handle 2; the hollow tube 15 is provided with a spring 9, The spring 9 is loc...

Embodiment 2

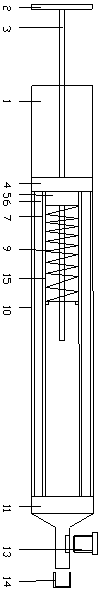

[0032] Such as figure 2 As shown, the middle part of the inner wall of the hollow tube 15 is provided with a boss, and the spring 9 is arranged between the piston 5 and the boss, which shortens the length of the spring 9 and reduces the cost. Others are identical to the structure described in Embodiment 1.

Embodiment 3

[0034] Such as image 3 As shown, the tapered portion of the discharge device 11 is provided with an adjustment device 13, and the size of the discharge port of the discharge device 11 is adjusted by the adjustment device 13 according to the size of the pad to control the flow rate of the liquid solder wire. Others are identical with the structure described in embodiment two.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com