A kind of asphalt smear forming machine for water blocking belt on both sides of the road

A technology of forming machine and water belt, which is applied in the direction of road, road, road repair, etc., and can solve the problems of poor effect of asphalt smearing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

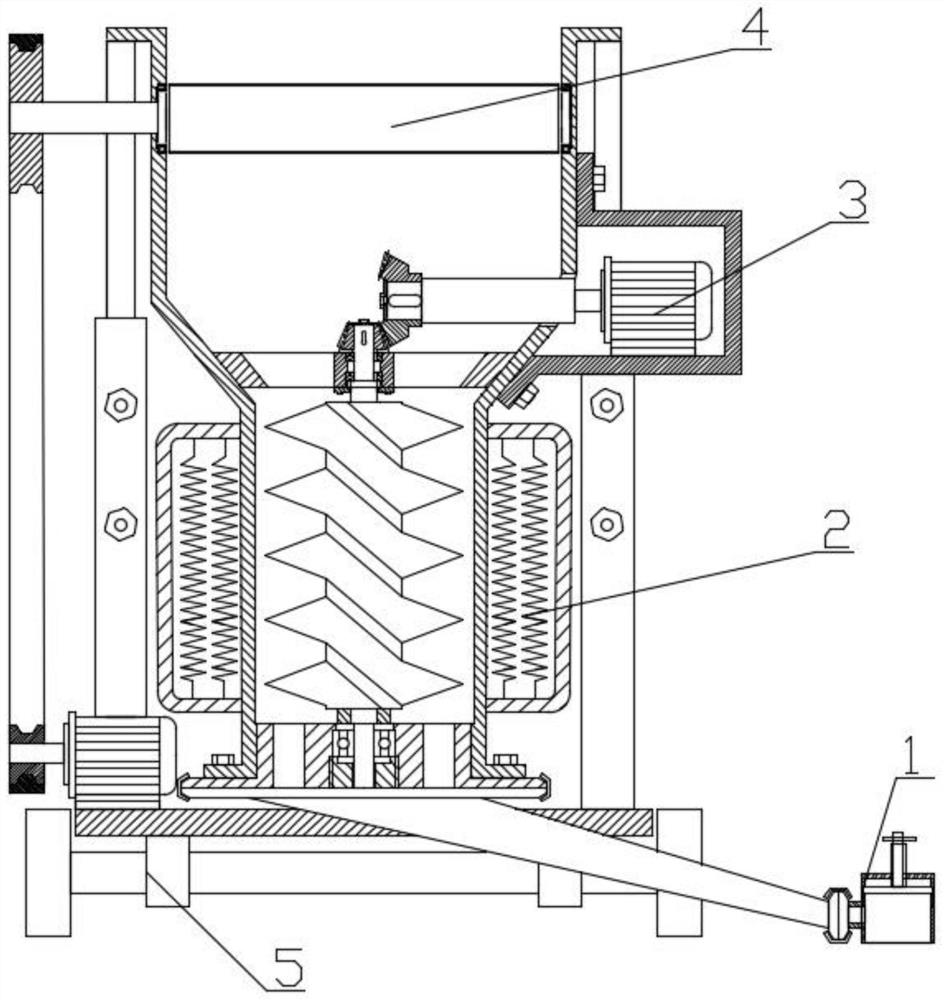

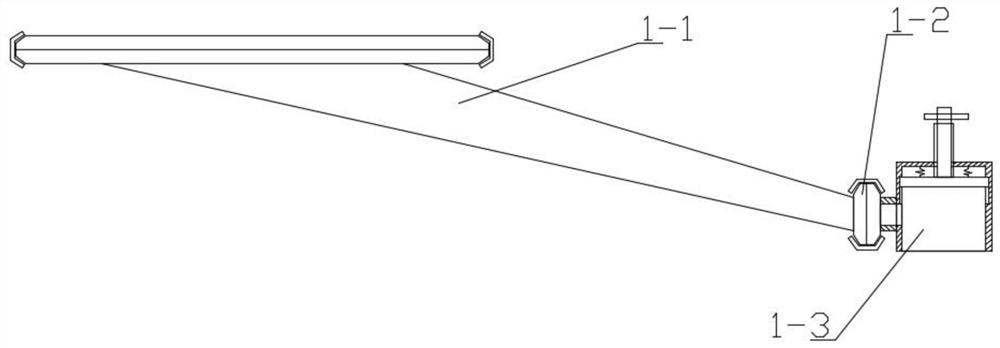

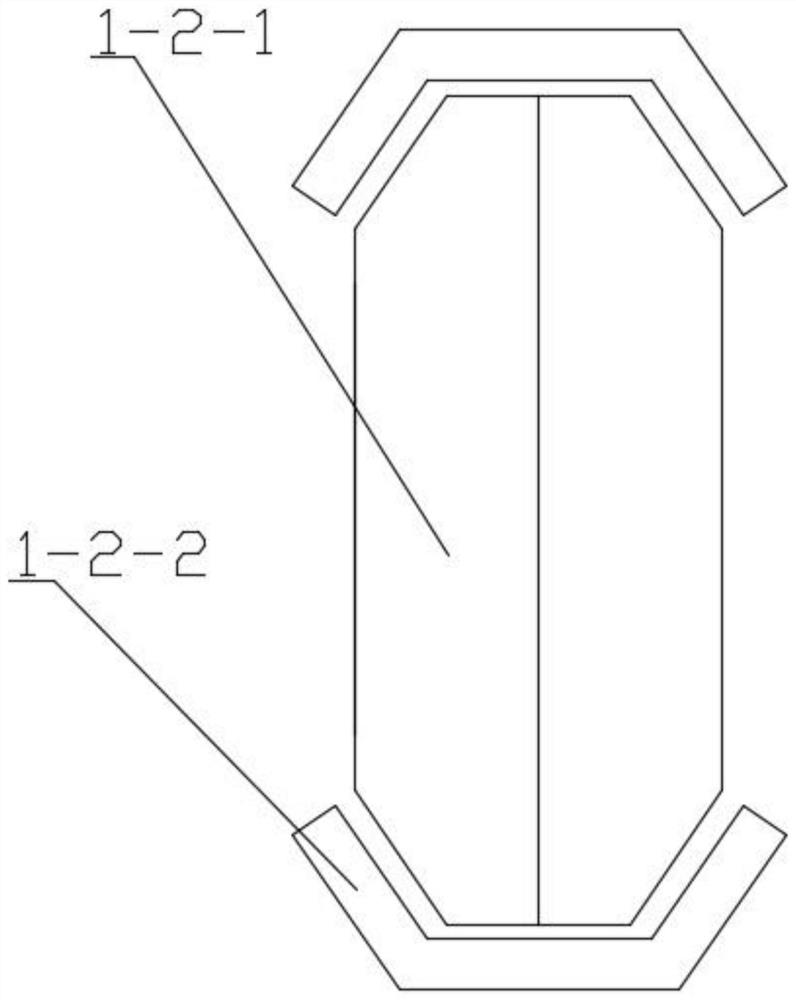

[0037] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12To illustrate this embodiment, the present invention relates to a forming machine for water barriers, more specifically, an asphalt smearing forming machine for water barriers on both sides of a road, which includes a forming mold combination 1, a heating combination 2, a mixing and feeding combination 3, a crushing Combination 4, frame combination 5, the crushing combination crushes the raw materials into small pieces, which is convenient to be heated and melted, and the stirring and feeding combination stirs the raw materials to fully mix different types of substances, so that the heating is uniform, and the molten materials It is guided downwards and advanced, and the height of the molding combination can be adjusted to meet various molding needs.

[0038] Forming mold combination 1 is composed of a mat...

specific Embodiment approach 2

[0051] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 This embodiment will be described, and this embodiment will further describe the first embodiment, and the number of the engaging sheaves 4-1 is two.

specific Embodiment approach 3

[0053] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 This embodiment will be described. This embodiment will further describe Embodiment 1, and the number of the displacement rods 5-2 is four.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com