A slab secondary cooling stepless adjustment device

A stepless adjustment and secondary cooling technology, which is applied in the field of metallurgical continuous casting, can solve problems affecting equipment casting life and stability, poor equipment stability and reliability, complex structure, etc., and achieve a wide range of market application prospects and sealing protection performance Excellent, simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

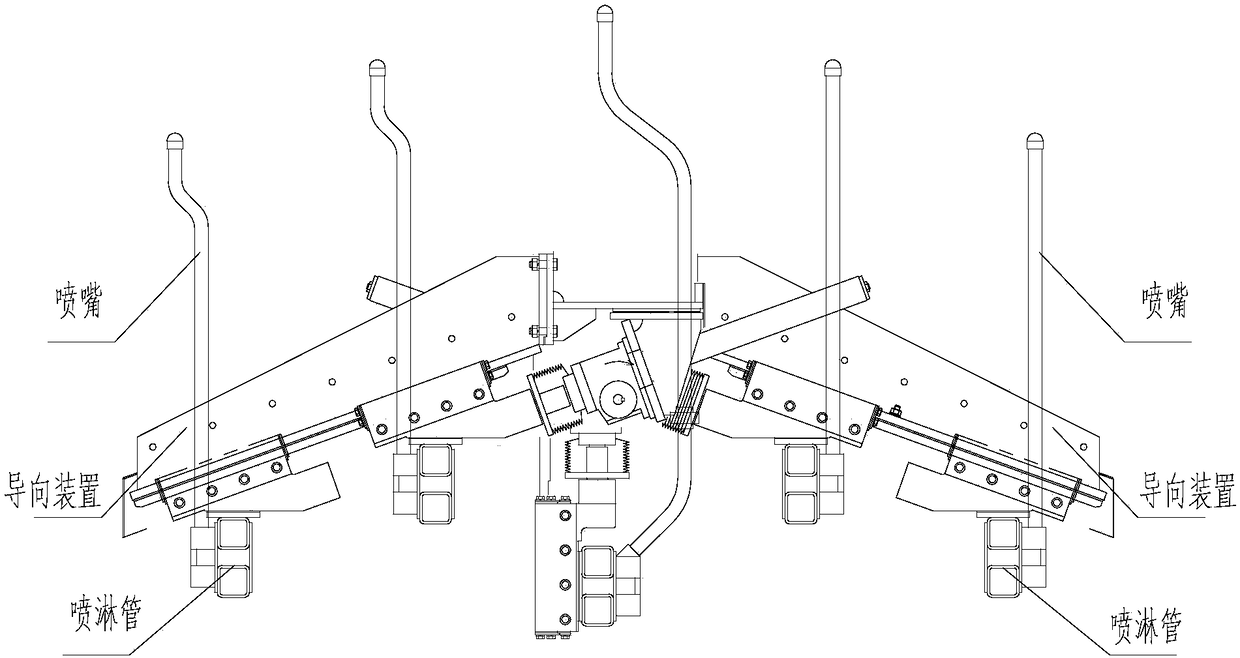

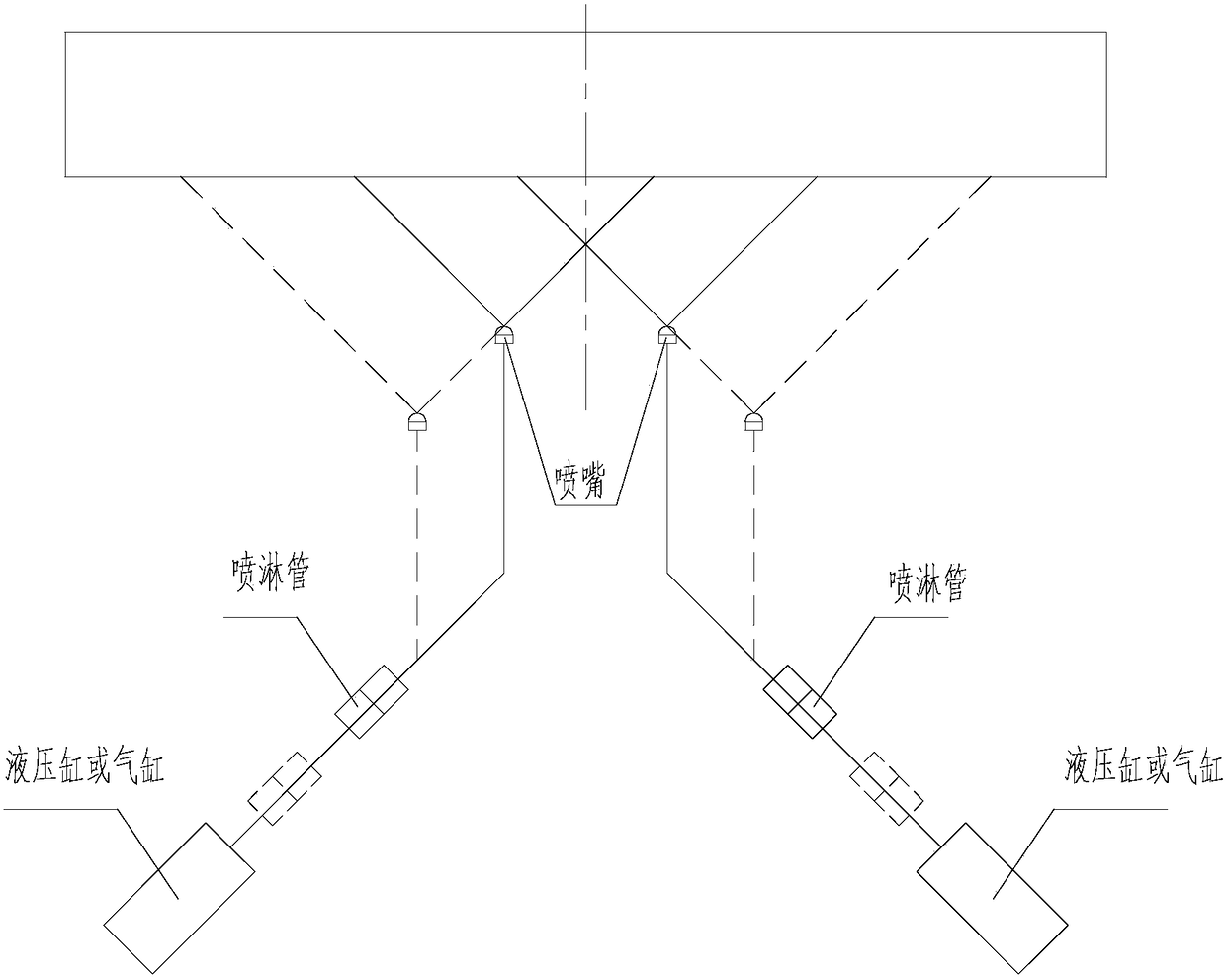

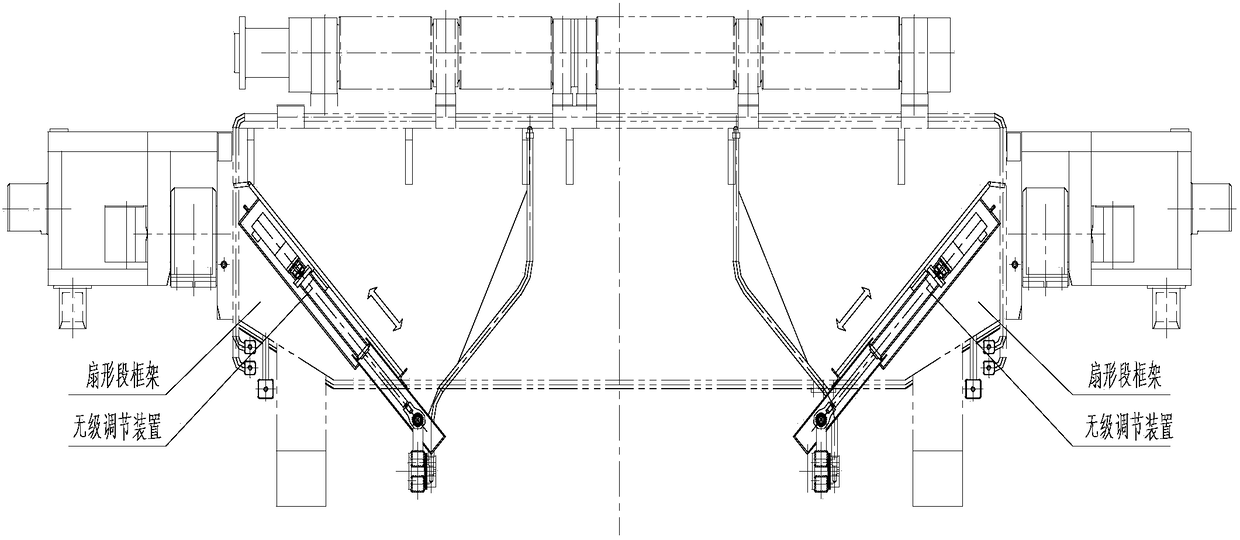

[0028] In this example, if image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a slab secondary cooling stepless adjustment device includes a motor 1, a reducer 2, an electric cylinder 3, a hinge shaft 4, a spray pipe 5, a nozzle 6, a guide device 7, a protective plate 8, and a fixed protective cover 9, telescopic protective cover 10 etc.

[0029] The slab secondary cooling stepless adjustment device is arranged on both sides of the fan section away from the center of the casting machine. Each set of stepless adjustment device is independently driven by motor 1; The torque is amplified, and the electric cylinder 3 receives the rotary motion and converts it into a linear motion. The motor 1 is connected to the reducer 2, the reducer 2 is connected to the electric cylinder 3, and the electric cylinder 3 is connected to the spray pipe 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com