Trench gate power transistor and manufacturing method therefor

A power transistor and trench gate technology, applied in the manufacture of trench gate power transistors, in the field of trench gate power transistors, can solve the problems of reducing the breakdown voltage and overall performance of power devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

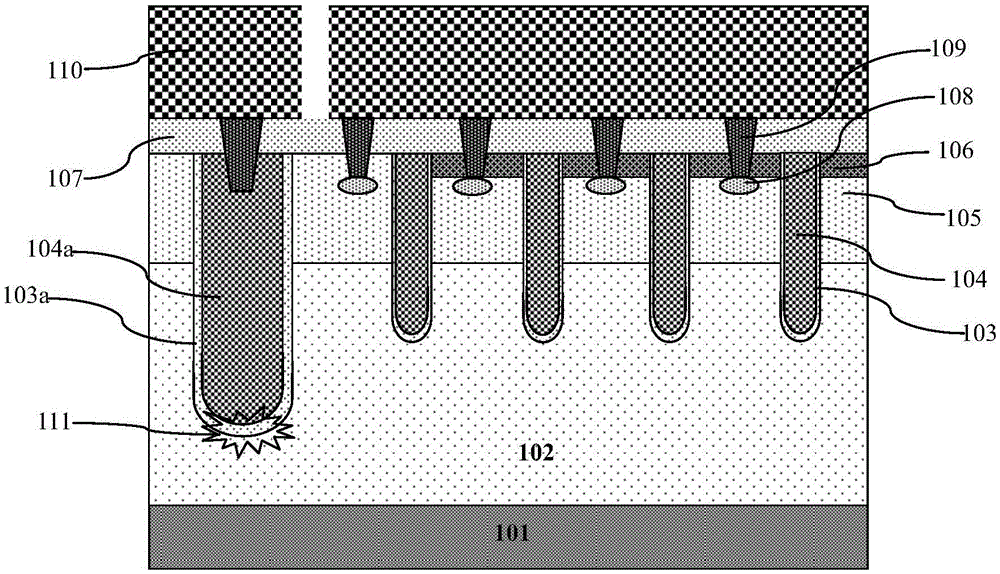

[0071] Such as figure 2 As shown, it is a schematic structural diagram of a trench-gate power transistor according to an embodiment of the present invention; the trench-gate power transistor according to an embodiment of the present invention includes:

[0072] A plurality of gate trenches formed in the device region of the semiconductor epitaxial layer 2, each of the gate trenches is arranged in parallel along the width direction, and each of the gate trenches is composed of a top trench and a bottom trench in the depth direction superimposed, the width of the top trench of each gate trench is greater than the width of the bottom trench so as to form a T-shaped structure;

[0073] A gate dielectric layer 3 is formed on the side and bottom surfaces of each gate trench, and gate polysilicon 41 is filled in the bottom trench of each gate trench, and a gate polysilicon 41 is filled in the bottom trench of each gate trench. The trench is filled with a first dielectric layer 42 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com