A calibrating device for a thermal neutron fluence rate in silicon single crystal irradiation channel in a nuclear reactor

A technology for nuclear reactors and calibration devices, which is applied in the fields of nuclear reactor monitoring, reactors, and nuclear engineering. The effect of sub-fluence rate in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

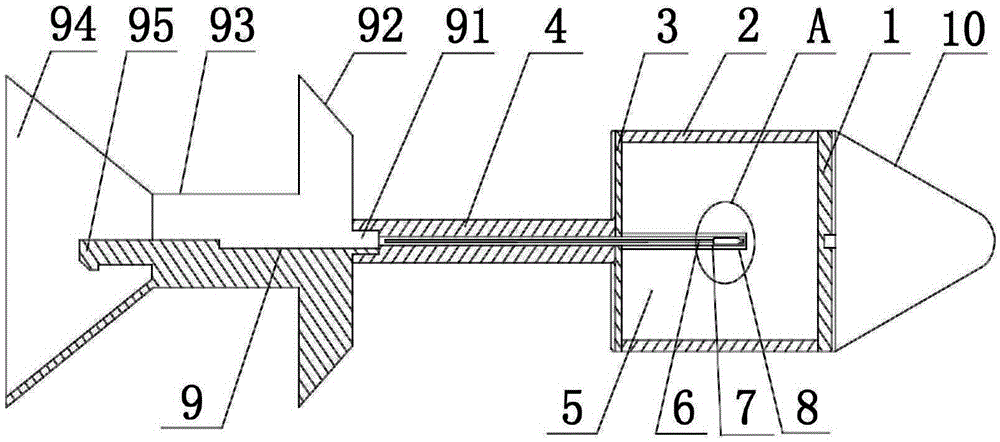

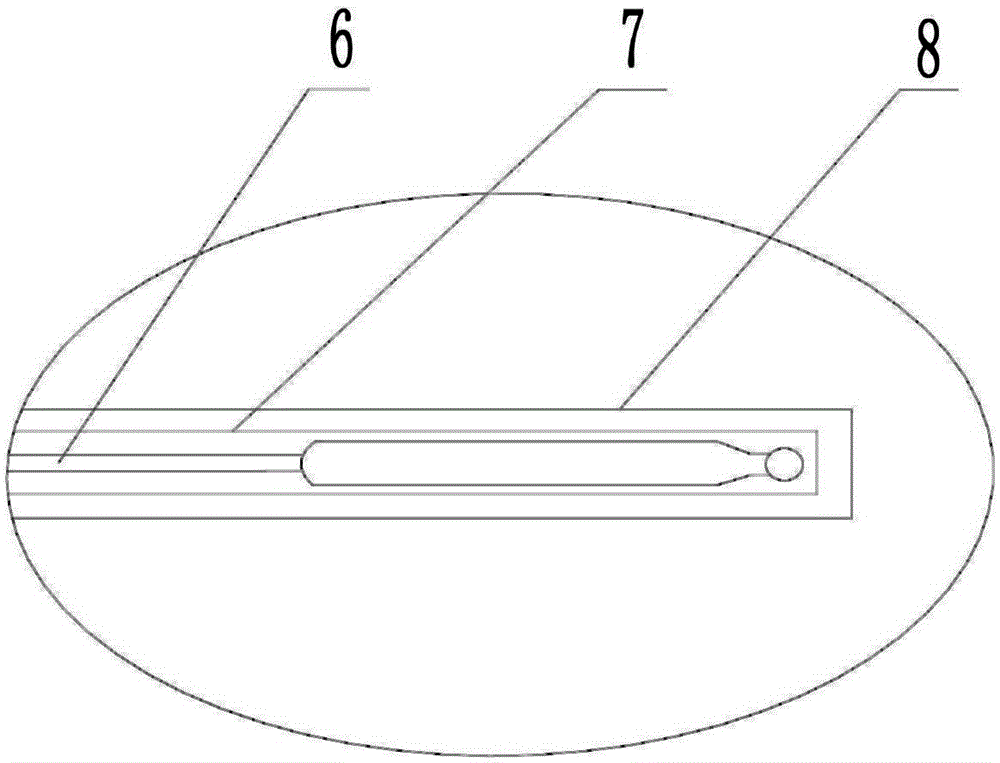

[0025] Such as figure 1 , figure 2 As shown, the calibration device for the thermal neutron fluence rate of the silicon single crystal irradiation channel of a nuclear reactor includes an aluminum cylinder 2, one end of the aluminum cylinder 2 is provided with a base 1, and the other end is provided with a top cover 3, and the top cover 3 A through hole is provided in the center of the aluminum cylinder body 2. A silicon single crystal rod body 5 is arranged inside the silicon single crystal rod body 5. A round hole is arranged on the axis of the silicon single crystal rod body 5. The opening end of the round hole is opposite to the through hole. The micro fission chamber 6 The sensitive section is inserted into the bottom of the round hole, the miniature fission chamber 6 is set in the fixed pipe 7, the hoisting head 9 is connected to the top cover 3 through the connecting column 4, and the connecting column 4 is provided with a through hole I that matches the through hole i...

Embodiment 2

[0027] Such as figure 1 , figure 2 As shown, this embodiment is based on Embodiment 1, and the silicon single crystal rod body 5 is consistent with the silicon conditions to be irradiated and processed; the depth of the circular hole is 7 / 10 of the length of the silicon single crystal rod body 5; One end of the tube 7 inserted into the aluminum cylinder 2 is sleeved with a sleeve 8 .

Embodiment 3

[0029] Such as figure 1 , figure 2 As shown, this embodiment is based on Embodiment 1, and a guide head 10 is provided on the outside of the base 1; the guide head 10 is a conical structure with an arc-shaped end.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com