Simulation method used for predicting heat condition parameter of high-temperature waste gas circulation sintering process

A simulation method and technology of state parameters, which are applied in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as low accuracy, low efficiency, and long simulation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0097] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

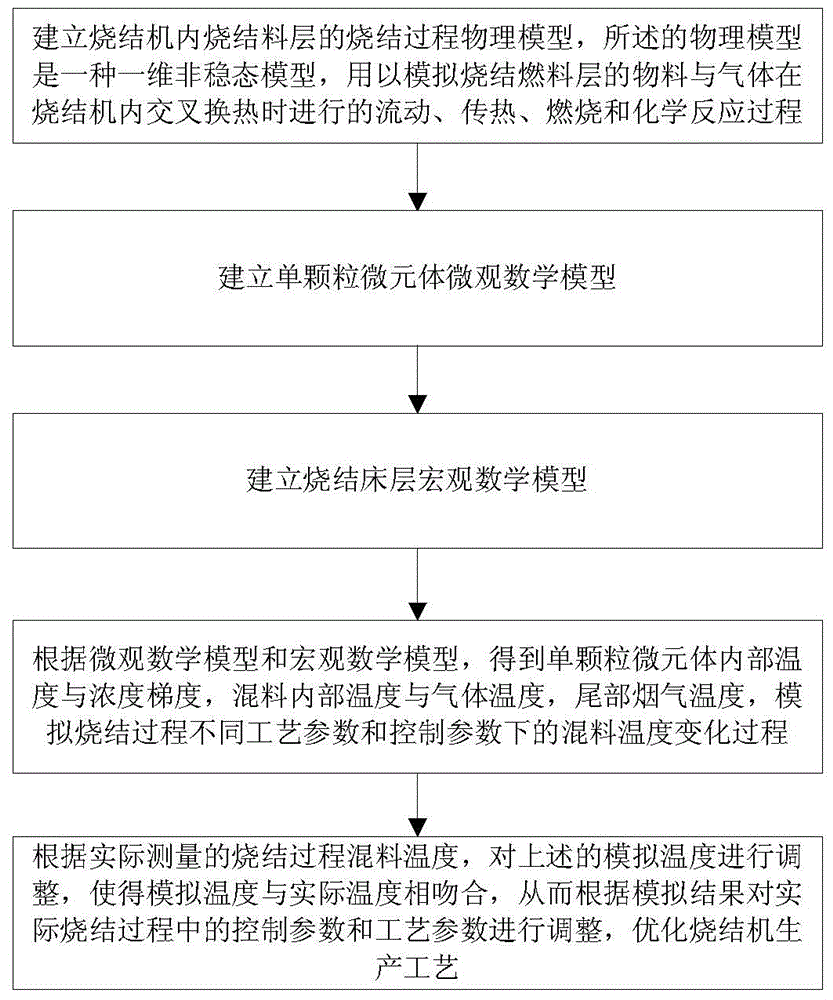

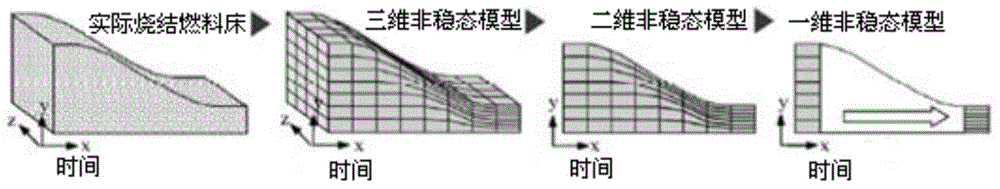

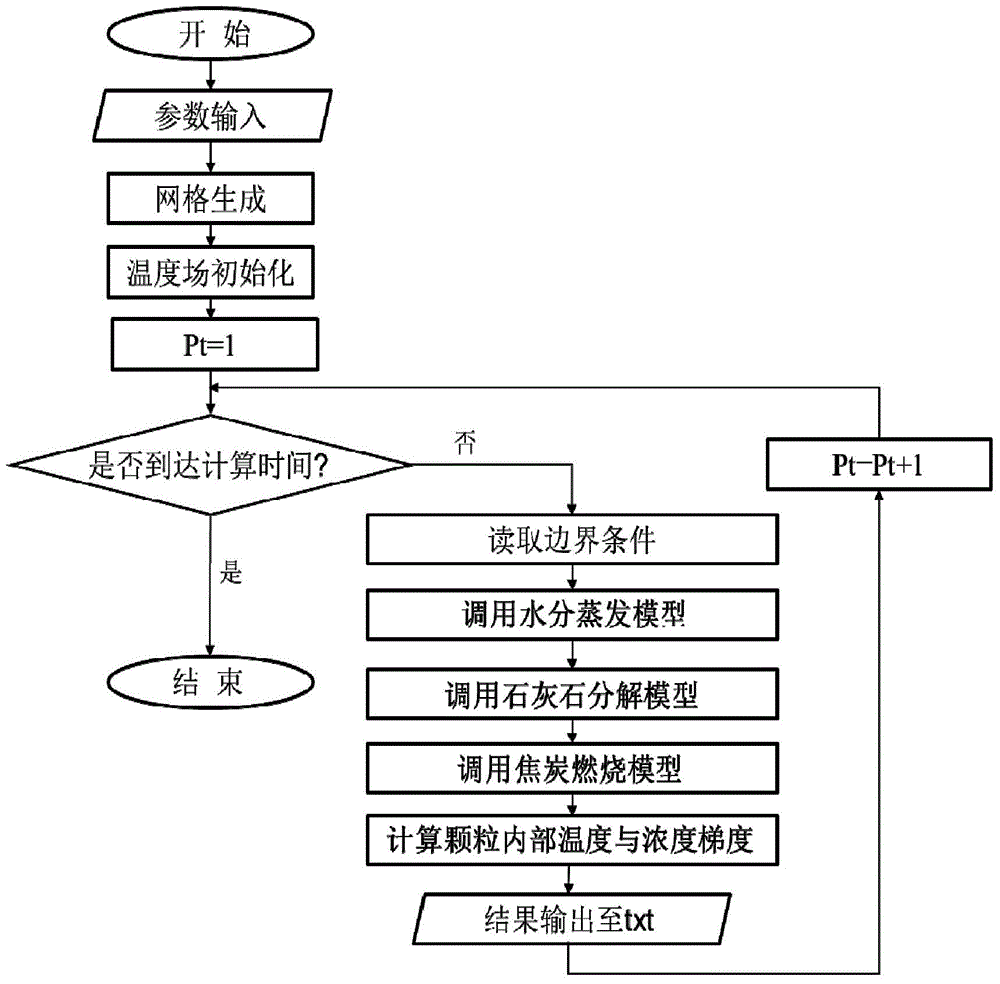

[0098] The present invention first establishes the physical model of flow / heat transfer / combustion and chemical reaction process in the sintering machine, and establishes the "mathematical model of flow / heat transfer / combustion and chemical reaction process in the sintering machine" on the basis of necessary simplified assumptions. Finally, the established mathematical model is verified and adjusted by actually measuring the temperature of each layer in the sintering cake, and the control parameters and process parameters in the actual sintering process are comprehensively analyzed and optimized.

[0099] In the past, the sintered material layer model was established as a macroscopic mathematical model, and the treatment of the heat of reaction in the model was too rough, so the calculation accuracy was slightly insufficient. To solve this pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com