Aspheric surface processing method of high-precision CVD ZnSe lens

A processing method and aspheric technology, applied in lenses, optics, instruments, etc., can solve the problems of difficult to remove the damage layer, the surface of the turning lens cannot reach the high-level surface defect index, and the center deviation index is not controlled by the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

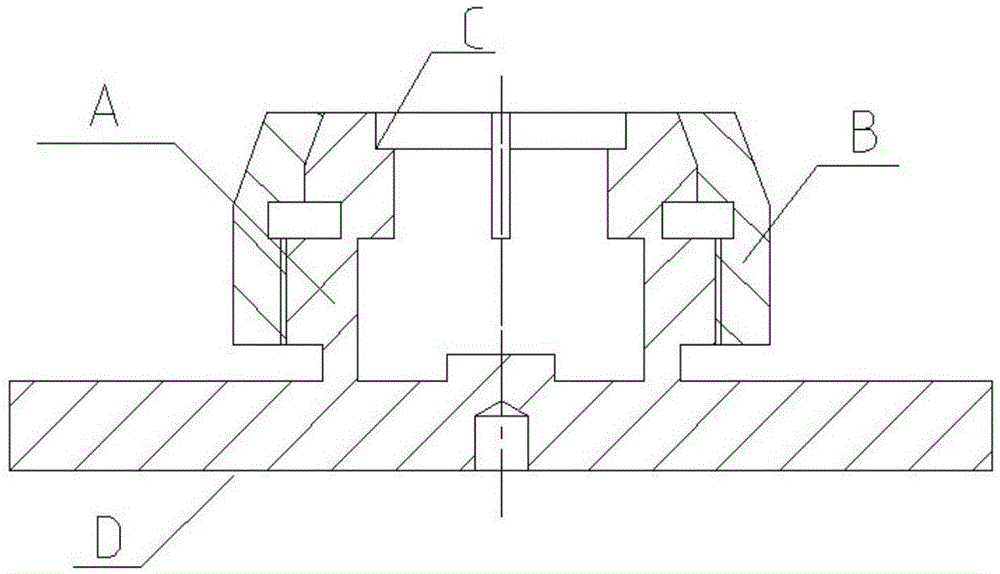

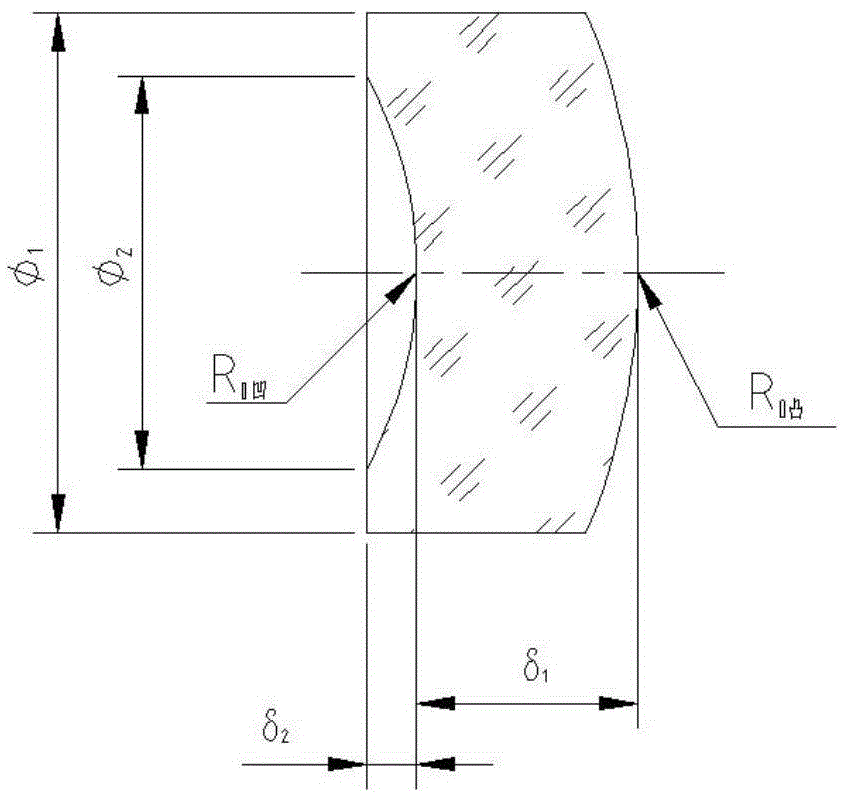

[0032] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

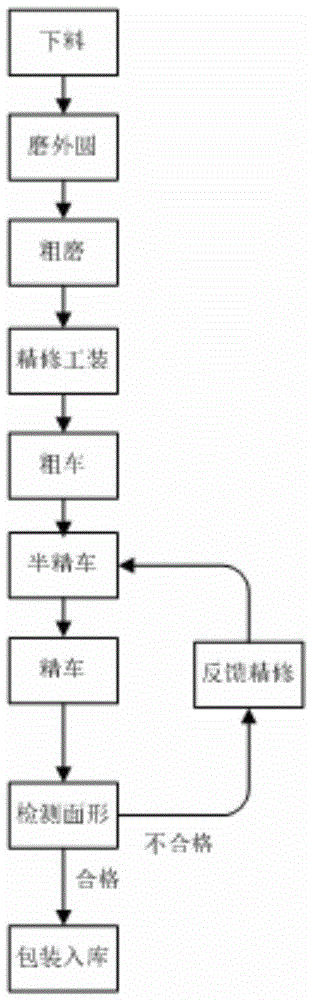

[0033] According to the method of the invention, aiming at the high-order aspheric CVDZnSe lens, a single-point diamond turning machine tool and a natural diamond arc cutter are used for ultra-precision turning processing. A kind of high-precision CVDZnSe lens aspherical surface turning processing method related to the present invention is described below in conjunction with accompanying drawing and embodiment, its processing technology flow see figure 1 .

[0034] The first step: cutting;

[0035] The second step: grinding the outer circle;

[0036] The third step: coarse grinding;

[0037] The fourth step: finishing tooling;

[0038] The fifth step: rough car;

[0039] The sixth step: semi-finished car;

[0040]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com