Vacuum tube bundle drying system with waste heat for multi-effect evaporation and airflow drying

A technology of tube bundle drying and multi-effect evaporation, which is applied in the direction of drying solid materials without heating, drying machine combination, drying solid materials, etc., can solve the problems of not being recycled, energy waste, waste steam containing dust, etc., and achieve material drying Thoroughly even, reduce energy consumption, avoid burnt effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

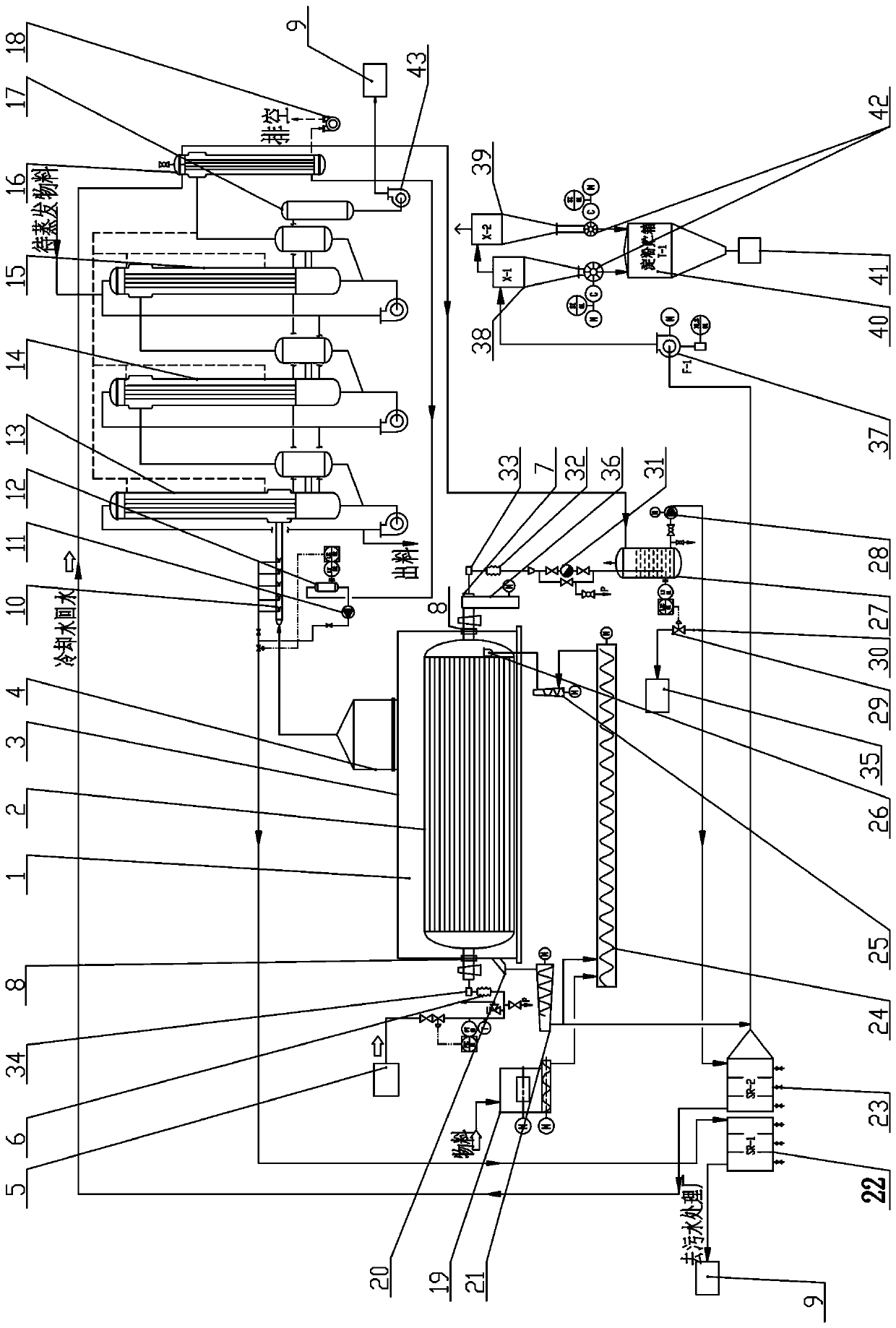

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] Such as figure 1 As shown, a vacuum tube bundle drying system in which waste heat is used for multi-effect evaporation and airflow drying includes tube bundle dryer 1, feeding auger 25, discharging auger 21, primary condensate water tank 27, primary condensate water pump 28, surface Condenser 16, secondary condensed water tank 17, secondary condensed water pump 43, primary air heat exchanger 22, secondary air heat exchanger 23, multi-effect evaporation system and airflow drying system, the tube bundle dryer 1 One side is provided with a feed port 26, and the other side is provided with a discharge port 20. The casing 3 of the tube bundle dryer 1 is provided with a secondary steam outlet 4. The shafts 7 at both ends of the tube bundle 2 of the tube bundle dryer 1 are connected to the 3. Vigorously connected by a mechanical seal 8, one end of the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com