Dry-type dual-clutch hydraulic combination and separation bearing assembly

A separation bearing and double clutch technology, applied in clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve problems such as uneven wear at the contact of the fork support surface, difficulty in gear shifting, and large impact noise, etc. Small size, smooth separation, no impact noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

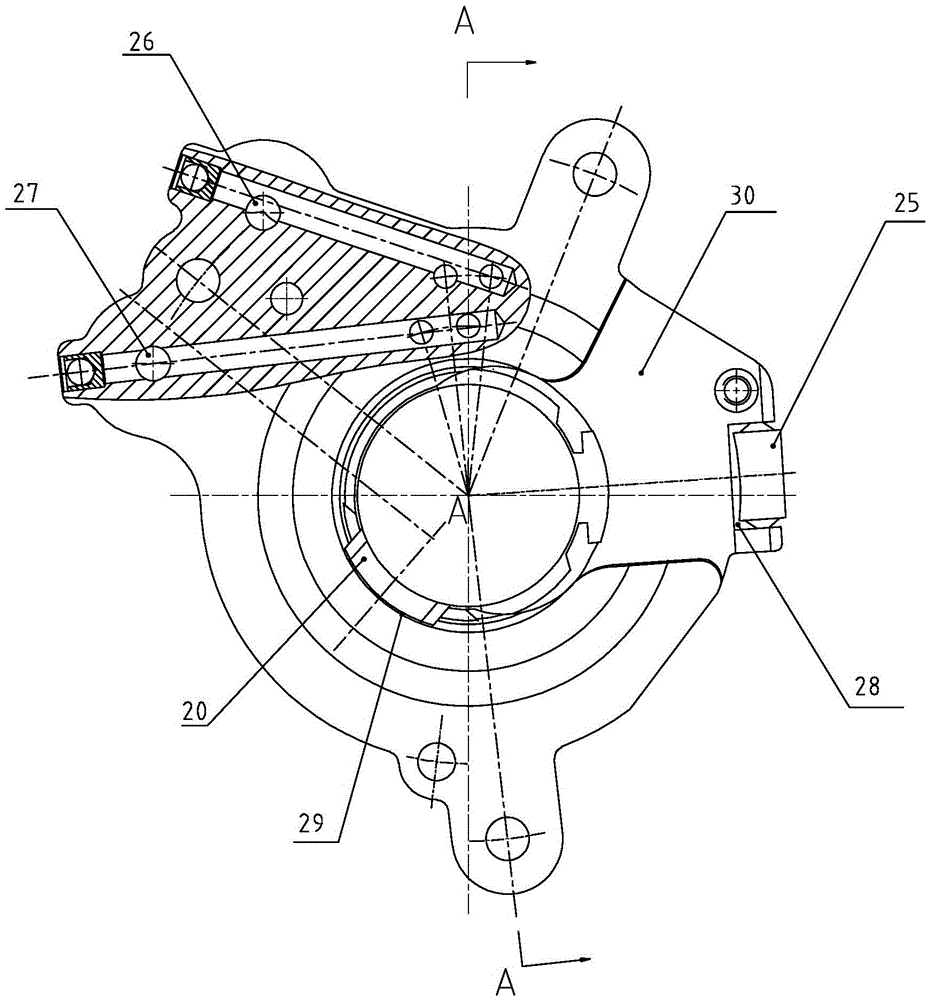

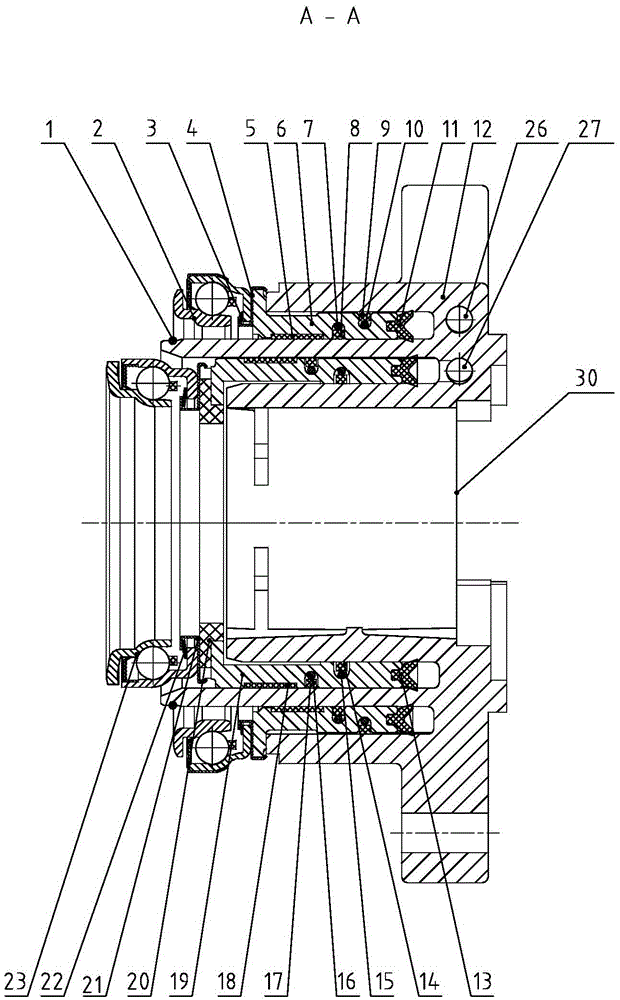

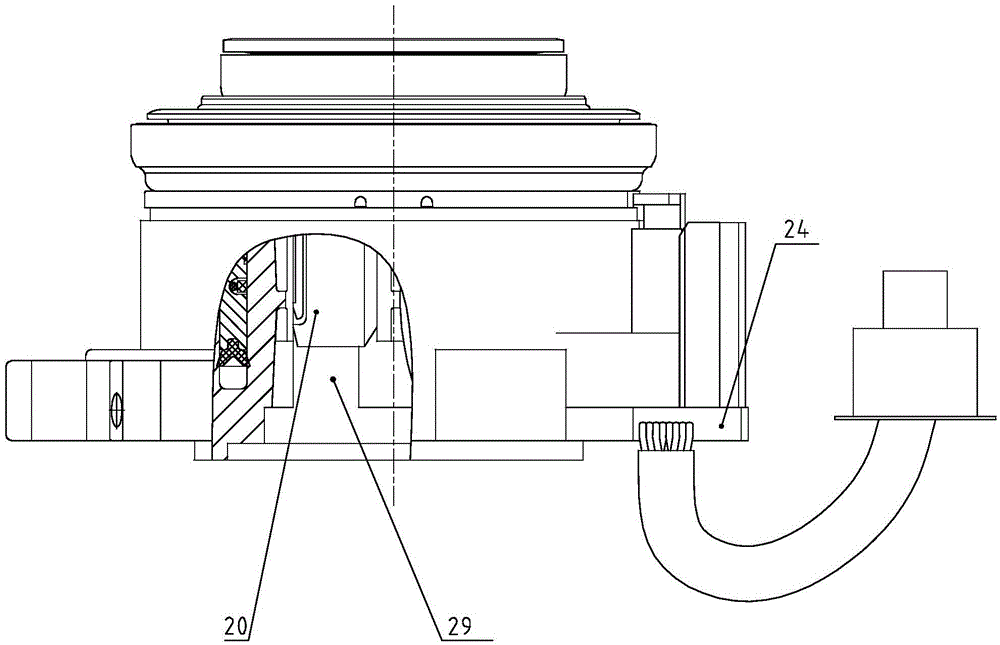

[0024] Such as Figure 1~6 As shown, the present invention mainly includes the first release bearing 2 , the first piston 6 , the second piston 19 , the cylinder body 12 and the second release bearing 23 .

[0025] The cylinder body 12 is made of lightweight materials. One end of the cylinder body 12 is provided with two coaxially arranged hydraulic chambers, and the other end of the cylinder body 12 is provided with a first liquid inlet channel 26 and a second liquid inlet channel 27. The liquid channel 26 and the second liquid inlet channel 27 communicate with the two hydraulic chambers respectively.

[0026] The first piston 6 and the second piston 19 are slidably connected to the two coaxially arranged hydraulic chambers of the cylinder body 12, the first piston 6 is provided with a first toothed connecting piece 4 on the outside, and the inner si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com