Hydraulic cylinder capable of adjusting throttling and cushioning stroke in two stages

A buffer stroke and adjustable technology, applied in the direction of fluid pressure actuating device, etc., can solve the problems of inability to adjust the time of the piston rod, weak repairability, impact of connecting equipment, etc., and achieve a simple structure, high pass rate, and easy processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

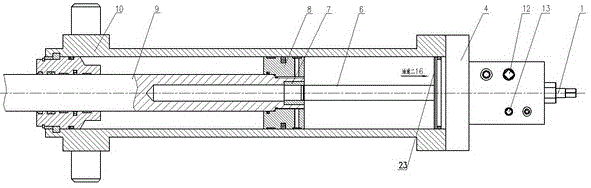

[0030] figure 1 , 2 Among them, the present invention includes a cylinder body 10, a piston rod 9, a valve block 4, a stroke adjustment rod 6 installed in the valve block 4, a control rod 1, an adjustment seat 2, a pad 3, a one-way valve 5, and a large throttle valve core 12, the small throttle spool 13, the buffer copper sleeve 7 that is contained in the piston rod 9. Piston 8 is installed on the piston rod 9 and is flush with the end face, and the center of the front end of the piston rod 9 is provided with an inner hole for cooperating with the stroke adjustment rod 6, and the buffer copper sleeve 7 is installed in the inner hole at the front end of the piston rod 9. The buffer copper sleeve 7 and the piston rod 9 are press-fitted and connected by a press-fit fit tolerance, and the set screw is clicked, and the depth of the inner hole of the piston rod 9 is greater than the stroke adjustment rod 6 to adjust the longest length. The valve block 4 is equipped with a stroke a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com