Device suitable for natural convection heat dissipation of surface of shell of refrigerator compressor

A refrigerator compressor and natural convection technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of ignoring the heat dissipation capacity of the compressor, increasing the heat load of the condenser, and increasing the power consumption of the compressor, etc. Achieve the effects of promoting flow, increasing heat flow velocity, and improving heat convection exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings, but the embodiments of the present invention are not limited thereto.

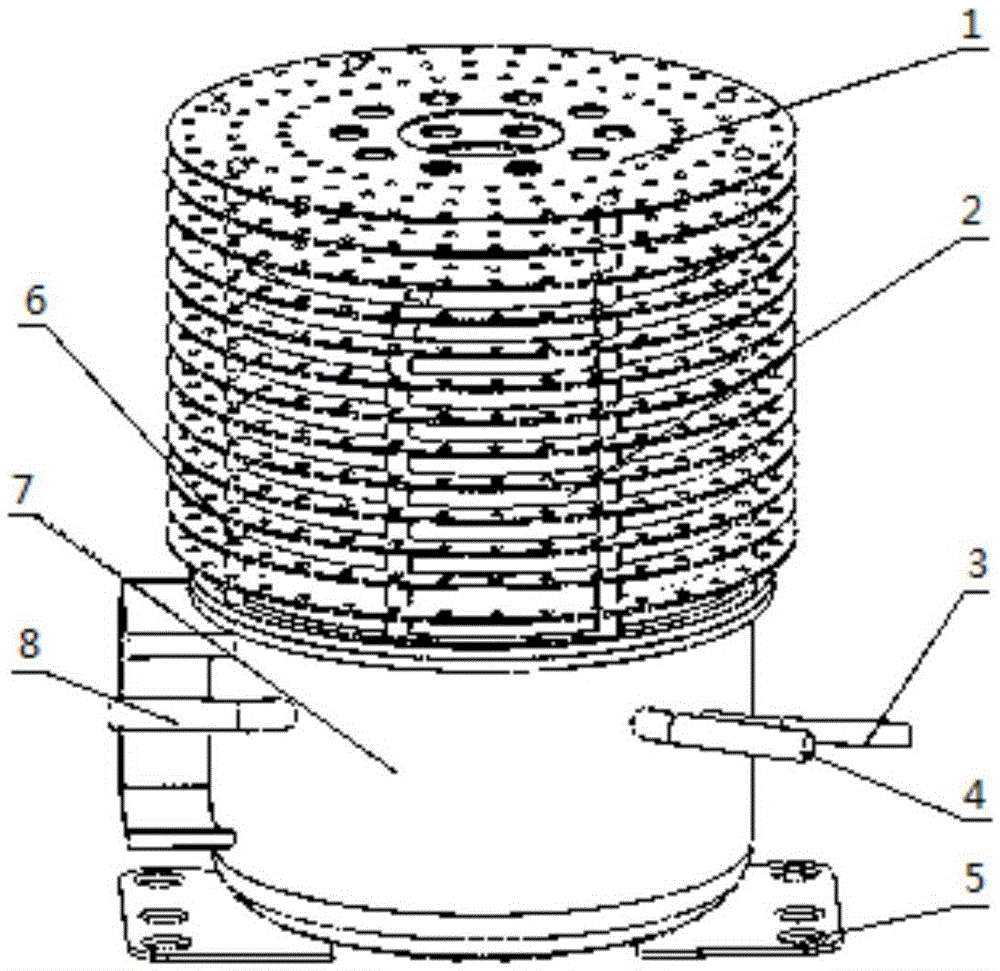

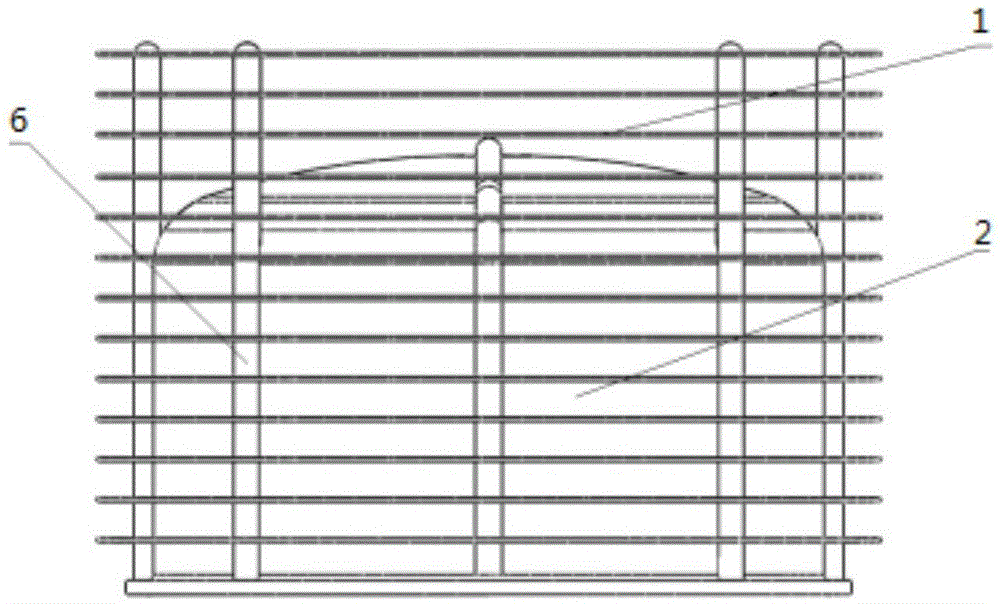

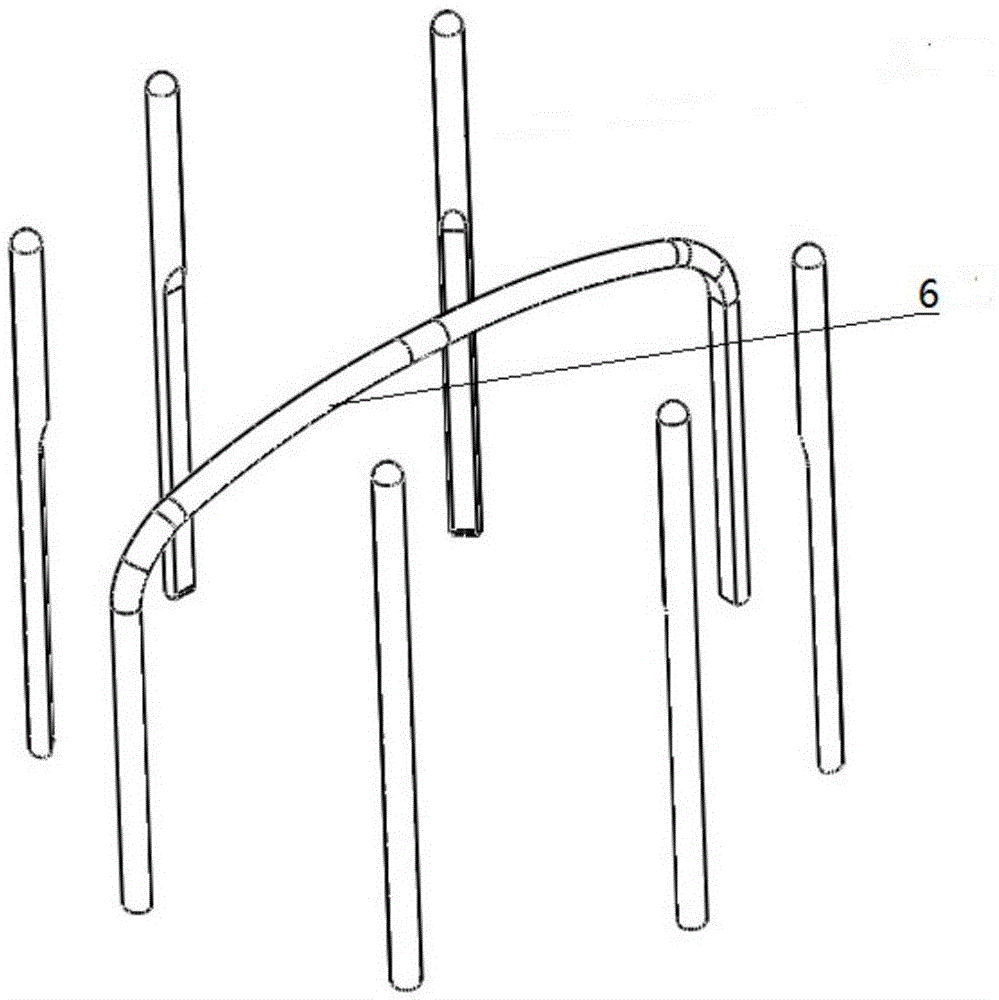

[0039] Such as figure 1 , 2 As shown, a device suitable for natural convection heat dissipation on the surface of the refrigerator compressor shell mainly includes a compressor upper shell 2, a compressor lower shell 7, a heat pipe 6 and a cooling fin 1; a compressor upper shell and a compressor lower shell The casings are all cylindrical, the upper casing of the compressor is provided with a top cover, the bottom of the lower casing 7 of the compressor has a base and a protrusion on the side, and the base has 6 bolt holes 5 for fixing, and the protrusion is open on one side , for external installation, the compressor upper casing 2 and the compressor lower casing 7 are tightly connected and assembled together to form a closed inner cavity. On th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com