Machinery pretreatment method for dissolving lignocellulose raw material

A technology of lignocellulosic raw materials and lignocellulose, which is applied in the processing of fiber raw materials, post-processing of cellulose pulp, and modification of pulp properties, etc. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

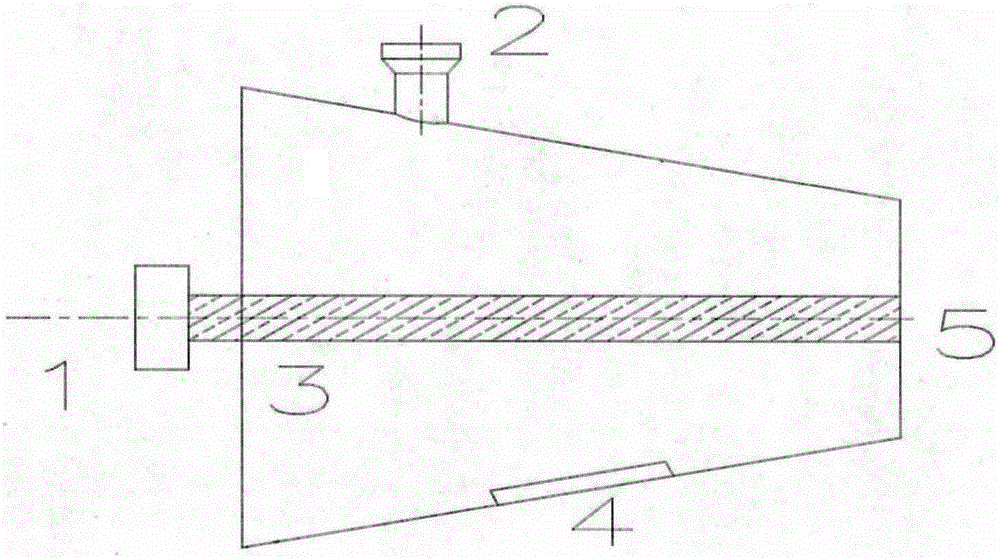

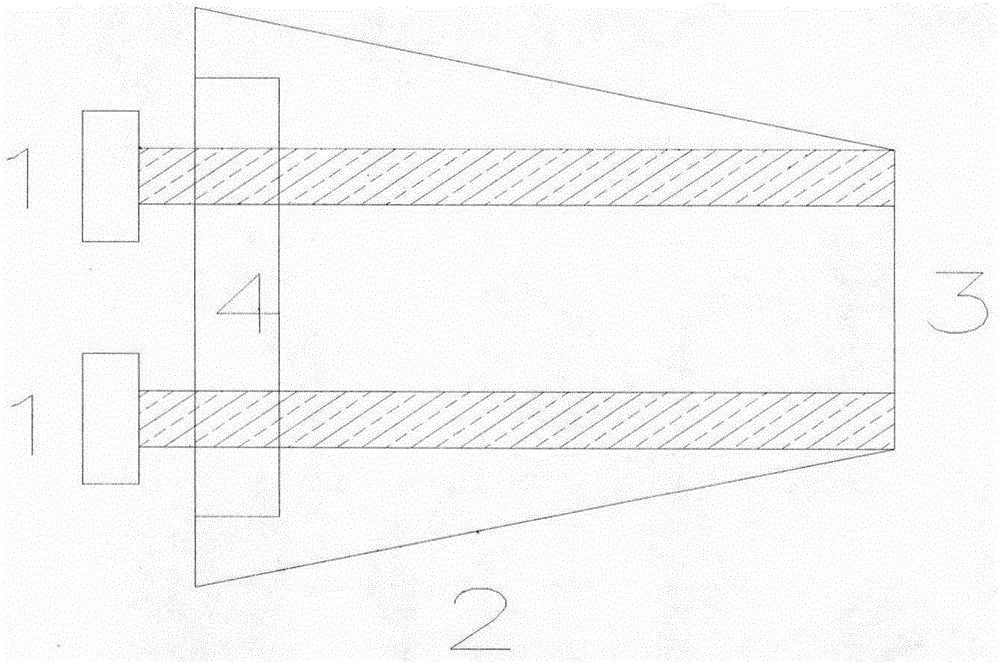

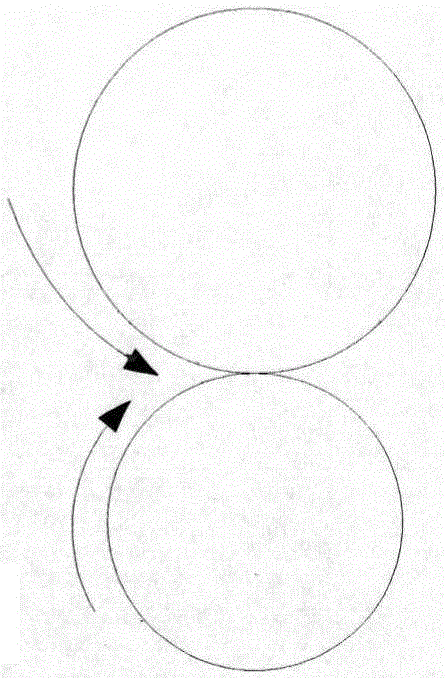

[0029] The present embodiment is as follows: Weigh 50 g of absolute dry lignocellulosic raw material and 400 g of glycerol into a 500 mL beaker, and heat the beaker in an oil bath at 100° C. for 1 hour. After it is fully swelled, the lignocellulosic-glycerol mixture is added to the mechanical pressing device, the lignocellulose raw material and soaking liquid stay in the conical screw for 20s, and the temperature is controlled at 70°C. The screw uses a single screw to advance the lignocellulosic raw material, making it knead and impregnate continuously, destroying the bonding force between lignocellulose, making it easier to disperse lignocellulose, and continuously refine the fiber bundles. Therefore, the aspect ratio increases, the specific surface area of lignocellulose increases, and the liquid absorption performance of lignocellulose is further improved. Add a small amount of H to the lignocellulosic raw material obtained by screw extrusion 2 SO 4 Carry out heating an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com