High-cost-performance and high-stain-resistance elastic flat-coating emulsion paint and preparation method thereof

A cost-effective latex paint technology, applied in latex paint, antifouling/underwater paint, coating, etc., can solve the problems of complex preparation methods, inability to have high stain resistance and high elasticity at the same time, and achieve easy mass production , The preparation method is simple and fast, and the effect of cheap cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

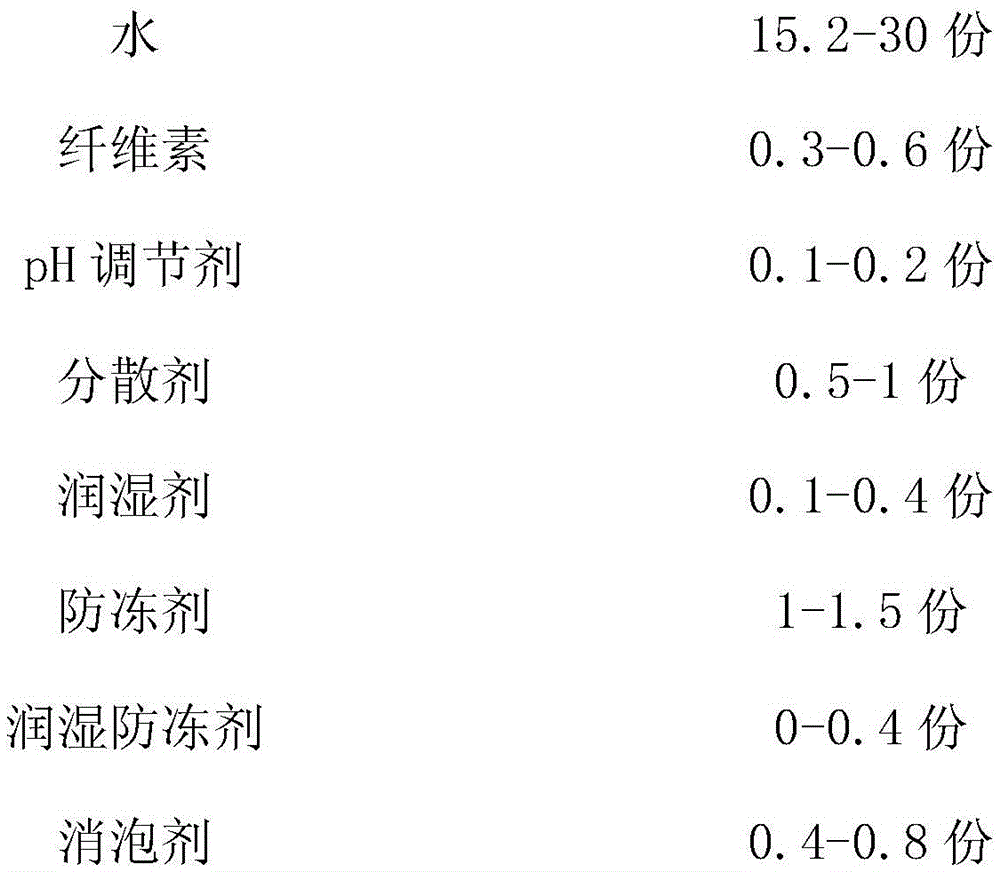

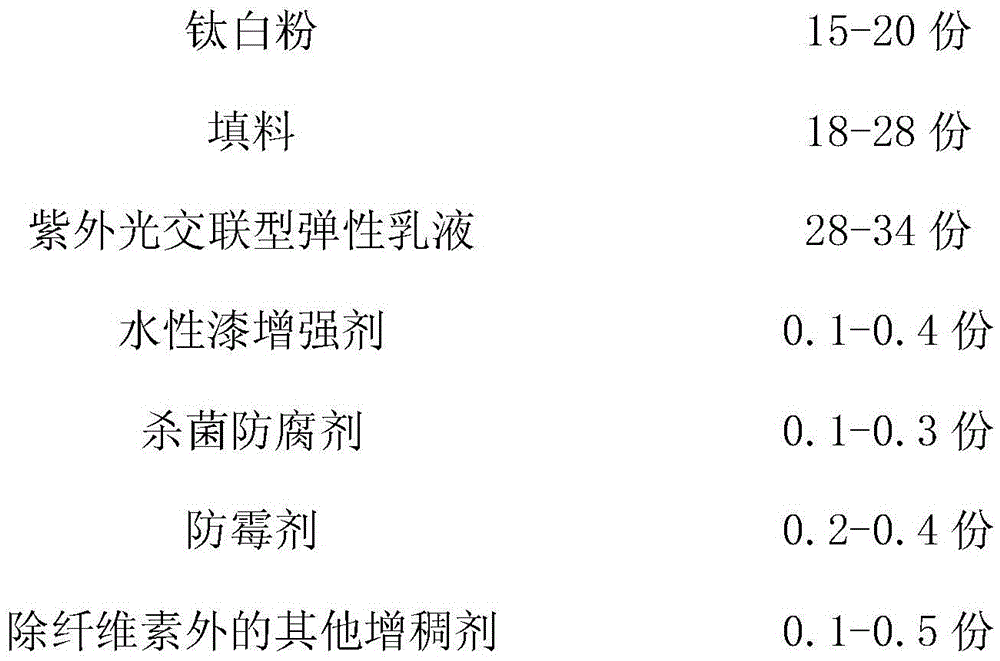

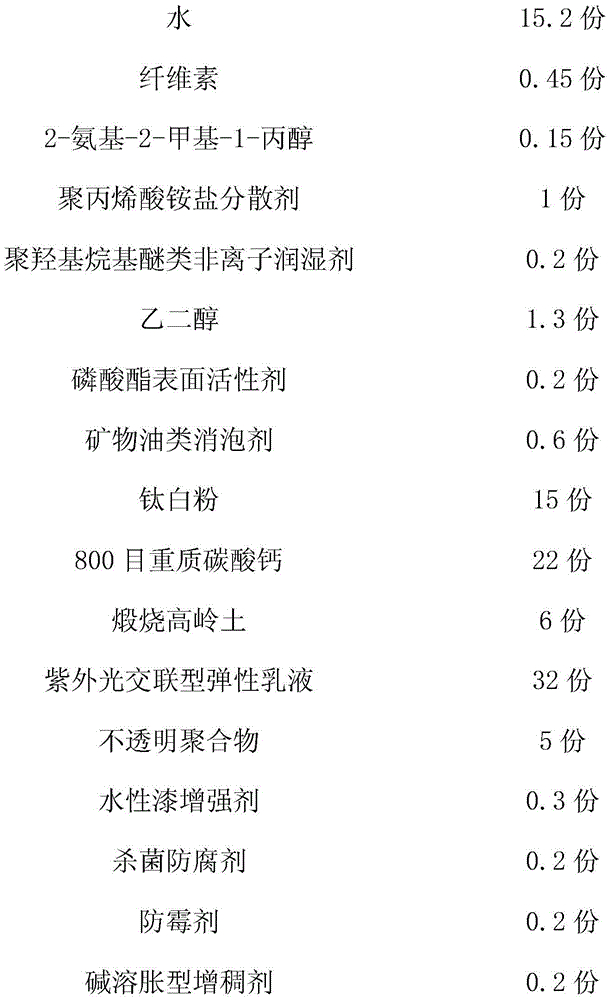

[0055] A high performance-price ratio and high stain-resistant elastic flat latex paint, which comprises the following components in parts by weight:

[0056]

[0057] Among them, 800 mesh heavy calcium carbonate and calcined kaolin are used as fillers.

[0058] The preparation method of the high cost performance and high stain resistance elastic flat latex paint comprises the following steps carried out in sequence:

[0059] ①At a speed of 500rpm, add cellulose to the water for mixing and disperse for 15 minutes;

[0060] ②Add 2-amino-2-methyl-1-propanol, polyacrylate ammonium salt dispersant, polyhydroxyalkyl ether nonionic wetting agent, ethyl alcohol to the mixture prepared in step ① at a speed of 800rpm Glycol, phosphate ester surfactant, mineral oil defoamer, titanium dioxide, 800 mesh ground calcium carbonate and calcined kaolin are mixed, and then the speed is increased to 1500rpm, and the mixture is dispersed to a fineness of ≤60μm at this speed, Wherein, the con...

Embodiment 2

[0063] A high performance-price ratio and high stain-resistant elastic flat latex paint, which comprises the following components in parts by weight:

[0064]

[0065]

[0066] Among them, 800 mesh heavy calcium carbonate, calcined kaolin and mica powder are used as fillers.

[0067] The preparation method of the high cost performance and high stain resistance elastic flat latex paint comprises the following steps carried out in sequence:

[0068] ①At a speed of 800rpm, add cellulose to the water for mixing and disperse for 8 minutes;

[0069] ②At the speed of 1200rpm, add pH regulator, polycarboxylate sodium salt dispersant, wetting agent, propylene glycol, water-based silicone defoamer, titanium dioxide, 800 mesh weight Calcium carbonate, calcined kaolin and mica powder are mixed, and then the speed is increased to 1800rpm, and the mixture is dispersed to a fineness of ≤60μm at this speed, and the amount of water-based silicone defoamer is 1 / 2 of its total weight ; ...

Embodiment 3

[0072] A high performance-price ratio and high stain-resistant elastic flat latex paint, which comprises the following components in parts by weight:

[0073]

[0074]

[0075] Among them, 800 mesh heavy calcium carbonate, calcined kaolin and precipitated barium sulfate are used as fillers.

[0076] The preparation method of the high cost performance and high stain resistance elastic flat latex paint comprises the following steps carried out in sequence:

[0077] ①At a speed of 600rpm, add cellulose to the water for mixing and disperse for 13 minutes;

[0078] ②At a speed of 1000rpm, add a pH regulator, a mixture of polyacrylic acid ammonium salt dispersant and polycarboxylate sodium salt dispersant, wetting agent, antifreeze, wetting antifreeze, mineral oil to the mixture prepared in step ① in sequence The mixture of antifoaming agent and water-based silicone antifoaming agent, titanium dioxide, and fillers are mixed, and then the speed is increased to 1600rpm, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com