A method of side milling error tool position planning based on non-developable ruled surface

A tool position and side milling technology, which is applied in the direction of milling machine equipment, milling machine equipment details, automatic control devices, etc., can solve the problems that the tool movement deviates from the ideal track, the wear of the transmission chain actuator, and the failure to meet the processing requirements, etc., to reduce the processing time. The effect of error, smooth processing process and efficient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

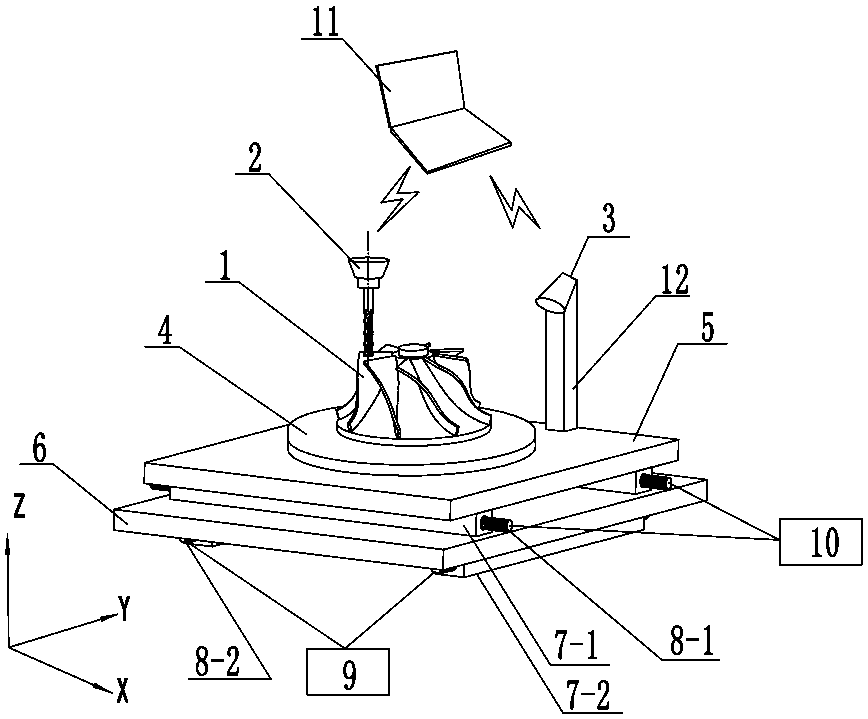

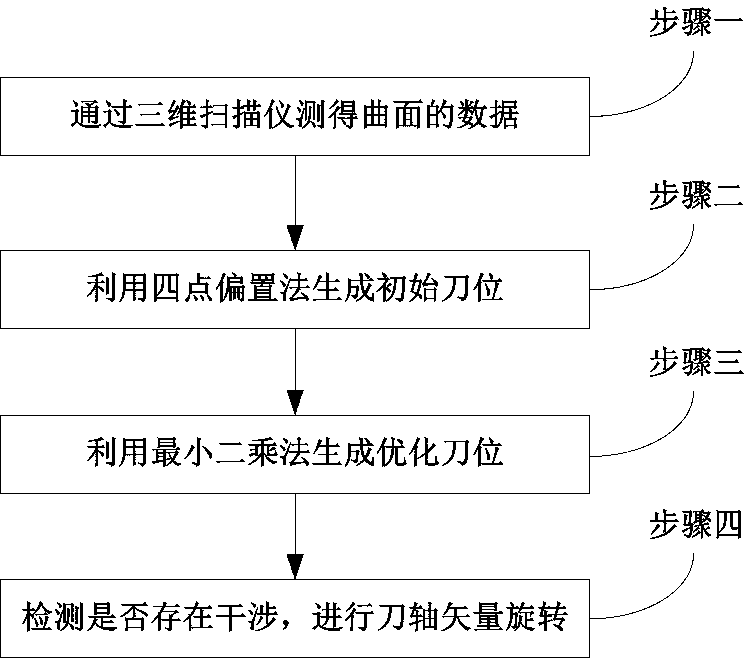

[0039] Such as figure 1 As shown, a side milling error compensation device based on a non-developable ruled surface includes a chucking plate 4, a workpiece 1, and a milling cutter 2 arranged above the workpiece 1 for side milling. On the chuck 4, it also includes a three-dimensional scanner 3, a microcomputer 11, a column 12 and a tool position compensation mechanism, and the tool position compensation mechanism is arranged below the chucking disc 4;

[0040] The tool position compensation mechanism includes: a first translation platform 5, a second translation platform 6, a first nut pair 7-1, a first lead screw 8-1, a second nut pair 7-2, a second lead screw 8- 2. The first servo motor 10 and the second servo motor 9; the first nut pair 7-1 is arranged under the first translation table 5, and the first lead screw 8-1 connects with the first nut pair 7-1 through balls. 1, the first lead screw 8-1 is connected to the output end of the first servo motor 10, the second nut pai...

Embodiment 2

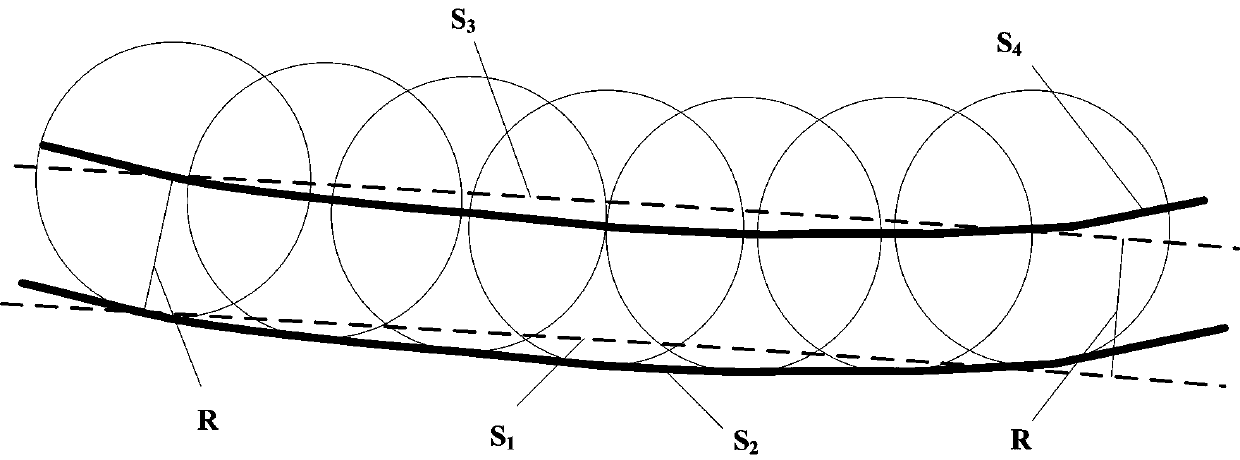

[0044] Because the non-developable ruled surface is characterized by the different normal vector directions of points on the straight generatrix, any tool with a non-zero radius will have a theoretical error in side milling, and the tool envelope cannot be completely tangent to the design surface. For the side milling of this curved surface, surface approximation processing is used, such as figure 2 As shown, the tool position planning of non-developable ruled surface in side milling mainly includes: design surface S1, tool envelope surface S2, equidistant surface S3 of design surface, tool axis trajectory surface S4, milling cutter envelope surface and tool axis The trajectory surface is a pair of equidistant surfaces. According to the range invariance under isometric mapping in differential geometry, the range between the tool envelope surface and the design surface is equal to the range between the tool axis trajectory surface and the design surface equidistant surface , s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com