Cleaning device for ammonia-containing waste gas

An exhaust gas purification device and exhaust gas technology are applied in the direction of gas treatment, air quality improvement, chemical instruments and methods, etc., which can solve the problems of secondary pollution, weak biological treatment capacity, and few manufacturers, and achieve high purification efficiency and good quality. The effect of economy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

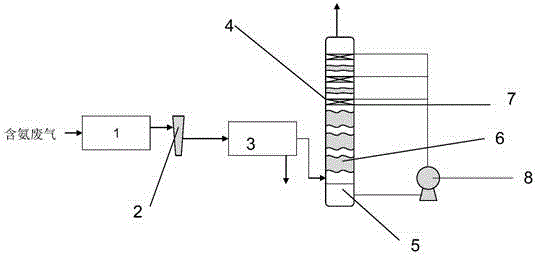

[0007] The present invention will be further described below in conjunction with the accompanying drawings. attached figure 1 middle:

[0008] 1 - heater;

[0009] 2 - cyclone separator;

[0010] 3 - condenser;

[0011] 4 - absorption tower;

[0012] 5-absorbing liquid tank;

[0013] 6- packing layer;

[0014] 7-spray layer;

[0015] 8-circulation pump.

[0016] see figure 1 , an ammonia-containing exhaust gas purification device, including a heater 1 connected in sequence, a cyclone separator 2, a condenser 3, and an absorption tower 4. The ammonia-containing exhaust gas first enters the heater 1, then enters the separator 2, and the condenser 3. The absorption tower 4 is removed from the top of the absorption tower. The height and diameter ratio of the absorption tower is 10:1. The absorption tower includes an absorption liquid tank 5 at the bottom, and a spray layer 7 at the top of the tower. The spray layer There are three layers in total, the lower part of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com