Cotton core embossing apparatus for diaper production line and embossing method thereof

A technology of production line and diapers, which is applied in the field of patent assembly manufacturing of diaper production line, can solve the problems of poor embossing effect, no heating function, poor applicability, etc., and achieve the effect of wide applicability and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

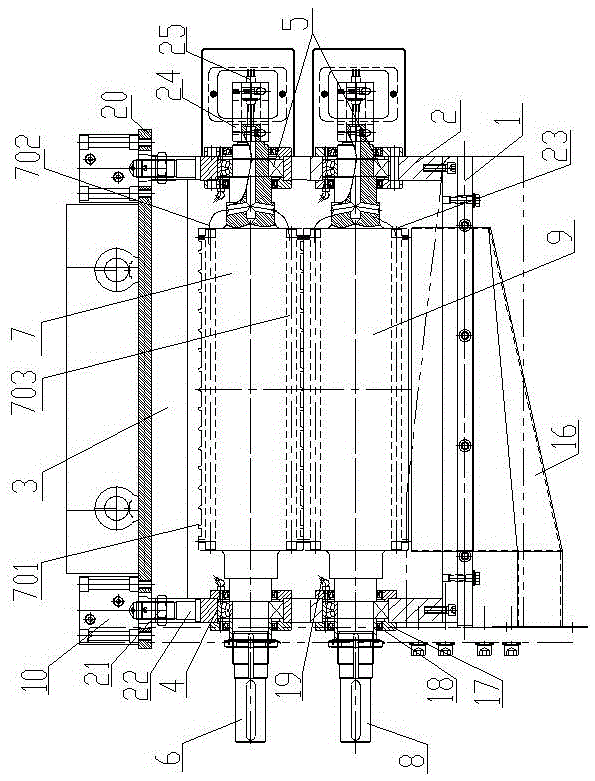

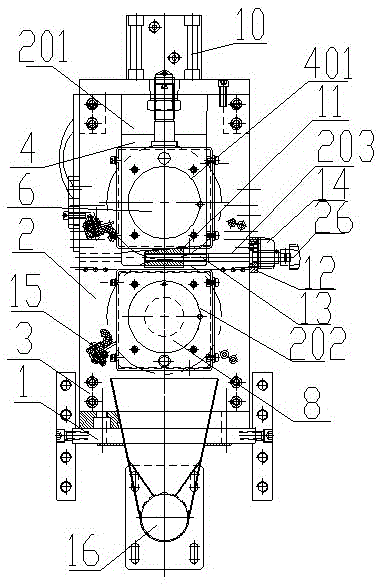

[0010] Embodiment 1: with reference to attached figure 1 and figure 2 . A special cotton core embossing device for a diaper production line, the knife box seat is installed on the wallboard of the diaper production equipment, and a concave knife holder plate 2 is provided on both sides of the bottom plate 1 of the knife box seat. Four spacer bars 3 are arranged between the knife rest plates 2 and two spacer bars 3 are positioned side by side at the upper ends of the two knife rest plates 2, and two spacer bars 3 are positioned side by side at the lower ends of the two knife rest plates 2, and the two tool rest plates are arranged side by side. The upper part of the plate 2 is provided with a groove 201, the groove 201 is provided with a slider 4, the fixed plate 20 is located on the upper end surface of the two tool holder plates 2, and the two oil cylinders 10 are respectively located at both ends of the fixed plate 20 and in the two oil cylinders 10. The piston rod passes...

Embodiment 2

[0017] Embodiment 2: On the basis of Example 1, an embossing method of a special cotton core embossing device for a diaper production line. After the oil cylinder 10 drives the slider to slide into place along the upper grooves 201 of the two knife rest plates 2, the The thickness of the embossed cotton core is adjusted by adjusting the screw to adjust the lower end surface of the slider 4 to match the pitch of the upper end surface of the inclined wedge 11. The oil cylinder drives the embossing roller to reset, and then sets the embossing roller 7 and the heat on the PLC controller. Heating temperature of roller 9; when working, when the large cotton core that has just been demolded enters the press mold formed by the embossing roller and the hot roller, the oil cylinder 10 drives the embossing roller 7 to press down, and the press mold is aligned with the newly demoulded mold. The large cotton core is embossed, and this cycle continues until the machine stops.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com