Adhesive sheet

A technology of adhesive sheet and adhesive layer, applied in the direction of adhesive type, ester copolymer adhesive, polyurea/polyurethane adhesive, etc. The effect of excellent stain resistance, good surface sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

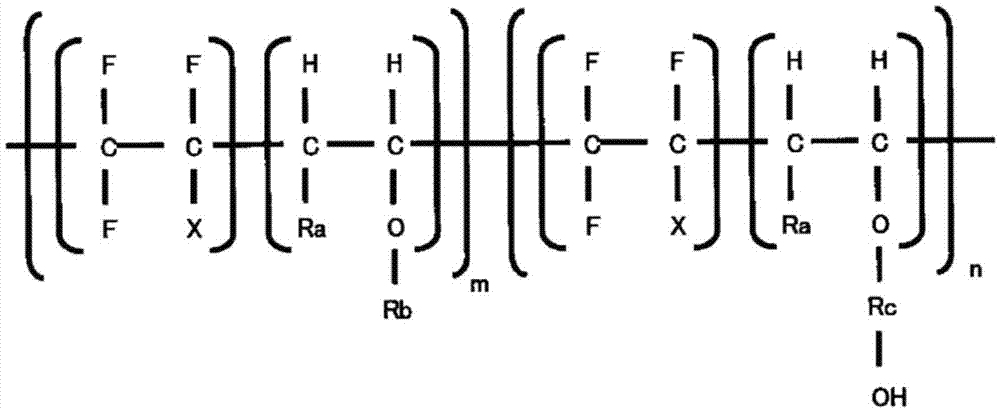

Method used

Image

Examples

Embodiment

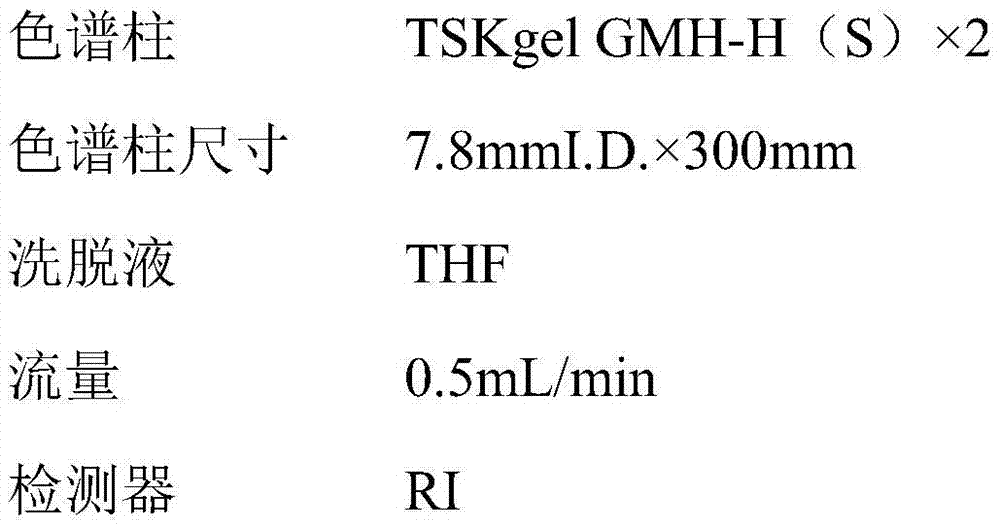

[0132] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to this. It should be noted that, in the following examples, unless otherwise stated, parts represent parts by weight, and % represents % by weight within the range of common knowledge without problems.

[0133] In addition, the measurement methods and evaluation methods used in the following examples are shown below. In the evaluation of the following stain resistance, the acrylic baking varnish white coating board (manufactured by Nippon Testpanel Co., Ltd.) used as the standard test board had an L* value showing 95.68 to 98.56, an a* value showing -1.26 to -1.01, The panel where the b* value shows a value of 0.16 to 1.52.

[0134] (measurement method and evaluation method)

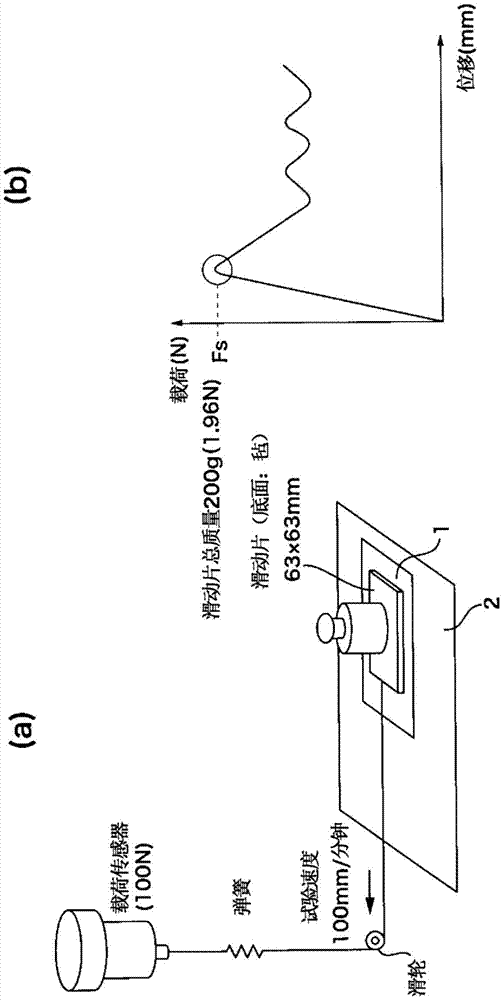

[0135] (1) Evaluation of flexibility (measurement of load at 5% elongation)

[0136] An acrylic adhesive layer having a thickness of 50 μm was formed on one surface of the substrate to prepare...

manufacture example 1

[0152] (Manufacturing example 1: Preparation of resin composition b1)

[0153] Add a 43% concentration solution based on ethyl acetate of acrylic resin (manufactured by Japan Shokubai Co., Ltd., trade name "hindered amine light stabilizer mixed UV-G301", the hydroxyl value of (meth)acrylic polymer is 45 (KOHmg / g)) 100 parts, isocyanate crosslinking agent (manufactured by Asahi Kasei Chemicals Corporation, trade name "DURANATETSE-100") 28.07 parts, and 108.8 parts of ethyl acetate as a diluting solvent to prepare the resin composition b1 for the surface protective layer.

manufacture example 2

[0154] (Manufacturing example 2: Preparation of resin composition b2)

[0155] 100 parts of a 70% concentration solution based on ethyl acetate of an acrylic resin (manufactured by Nuplex Resins GmbH, trade name "SETALUX DA870BA", hydroxyl value of (meth)acrylic polymer 99 (KOH mg / g)) 100 parts, isocyanate crosslinking agent (Manufactured by SumikaBayerUrethane Co., Ltd., trade name "SUMIDURN3300") 34.00 parts and a mixed solvent of ethyl acetate and xylene (ethyl acetate / xylene=1 / 1wt%) 51.31 parts as a diluting solvent to prepare a surface protection Layer resin composition b2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com