Thin inductor structure and manufacturing method

An inductance and thin technology, applied in the field of inductance, can solve the problems of low efficiency and complicated manufacturing process of thin inductance structure, and achieve the effect of increasing output, simplifying manufacturing process and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

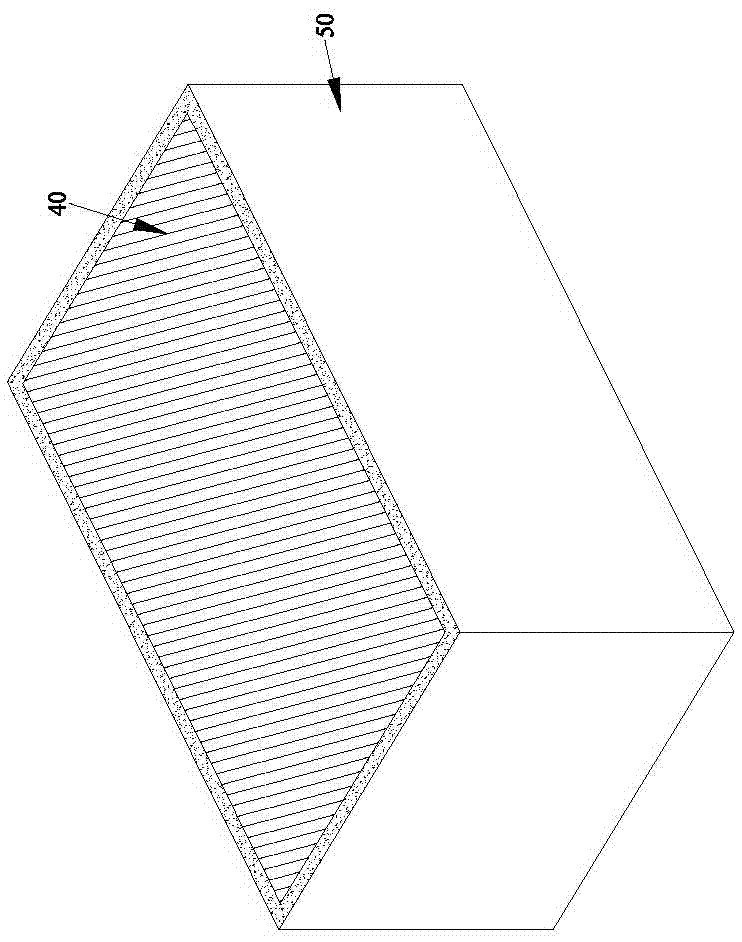

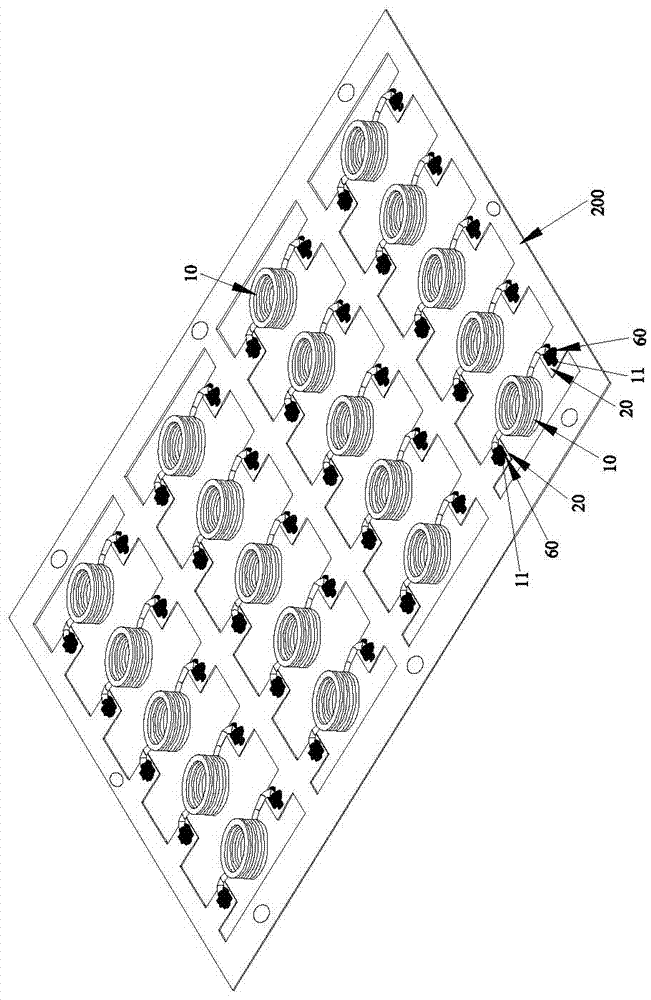

[0034] Please refer to Figure 1 to Figure 8 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a coil 10 , two electrode terminals 20 , a first magnetically conductive sheet 30 , a second magnetically conductive sheet 40 and a body 50 .

[0035] The coil 10 has two pins 11. Specifically, the coil 10 is composed of a copper wire and an insulating layer covering the copper wire.

[0036] The two electrode terminals 20 are arranged at intervals, and the two electrode terminals 20 are respectively electrically connected to the aforementioned two pins 11 .

[0037] The first magnetically conductive sheet 30 is disposed between the two electrode terminals 20 and below the coil 10 , and the second magnetically conductive sheet 40 is disposed above the first magnetically conductive sheet 30 .

[0038] The main body 50 is a mixture of iron powder and plastic. The main body 50 covers the coil 10 and adheres the first magnetic cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com