Real-time monitoring networking main control system for numerical control machine tool

A technology of CNC machine tools and master control systems, which is applied in the field of real-time remote monitoring networked master control systems and CNC machine tool monitoring systems. cost, ease of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

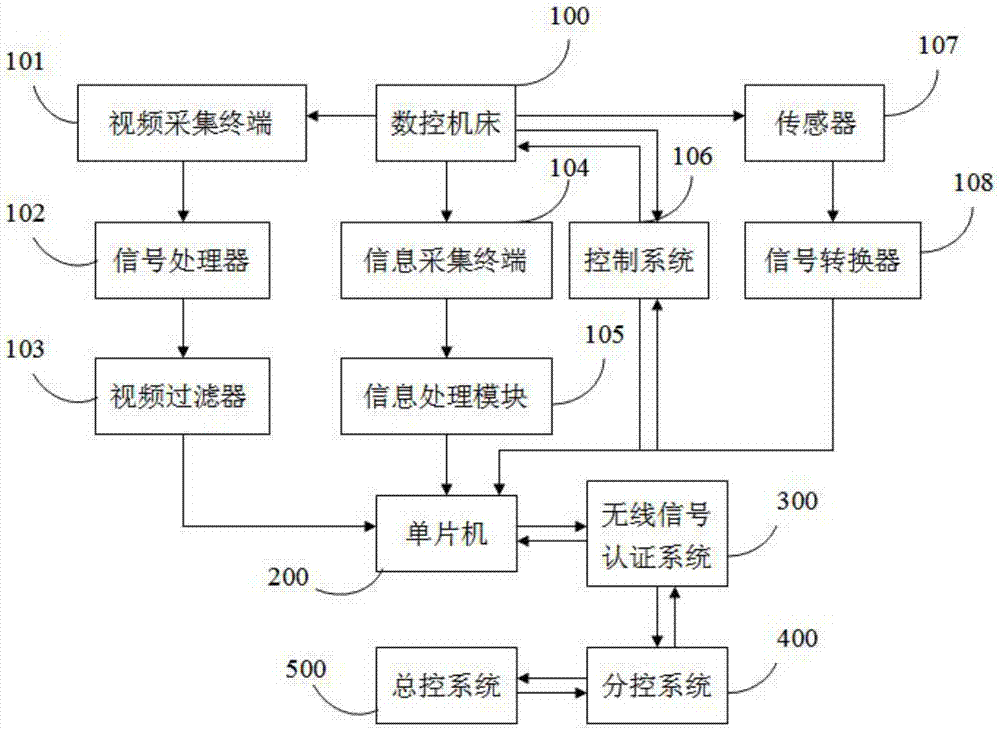

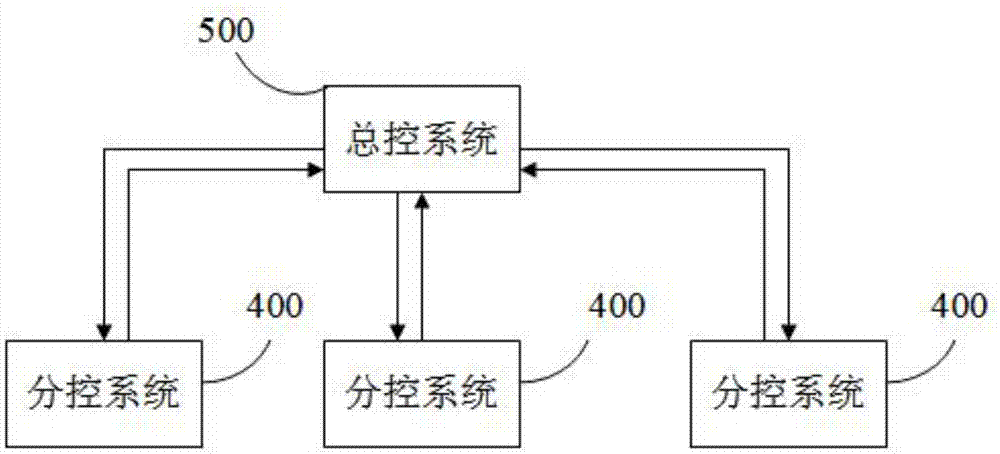

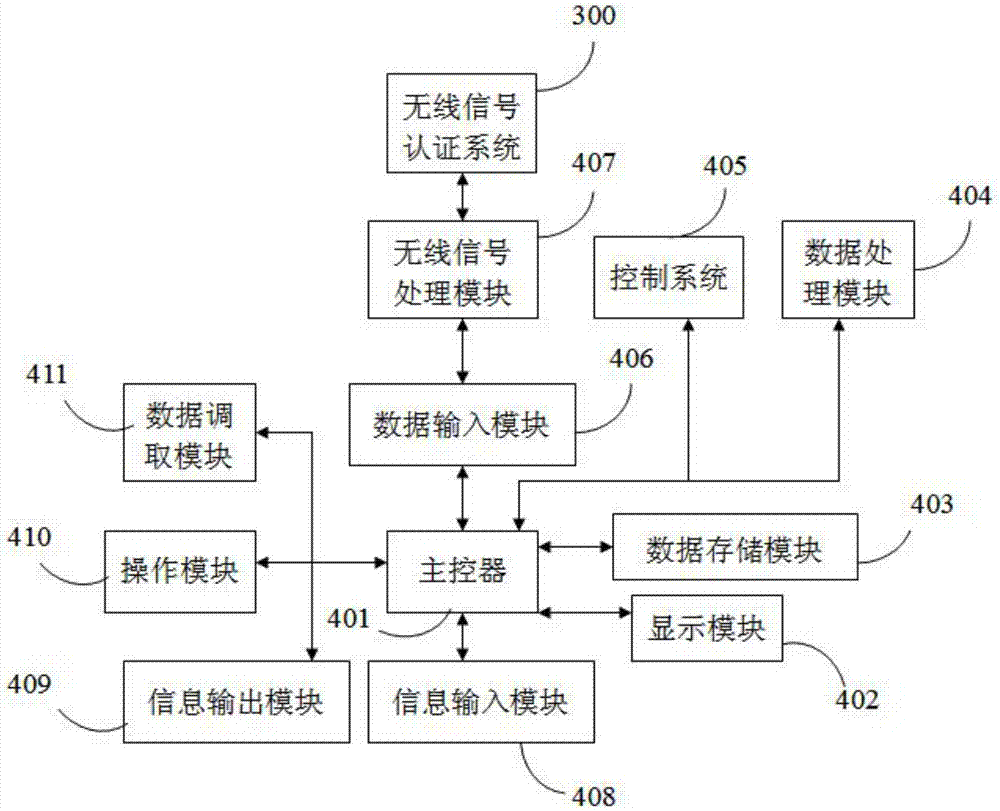

[0031] Such as figure 1 with figure 2 As shown, a real-time remote monitoring networked general control system of a CNC machine tool includes a CNC machine tool 100 and a control system 106, the control system 106 is connected to a single-chip microcomputer 200, and the single-chip microcomputer 200 is connected to a wireless signal authentication system 300, The wireless signal authentication system 300 is wirelessly connected with a sub-control system 400, the sub-control system 400 is connected with a master control system 500, and the wireless signal authentication system 300 is used to connect the single-chip microcomputer 200 with the sub-control system 400...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com