Optical element structures capable of being spliced

A technology of optical components and assembly parts, applied in the field of lighting systems, can solve problems such as not being specifically taught or disclosed, and achieve the effect of increasing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

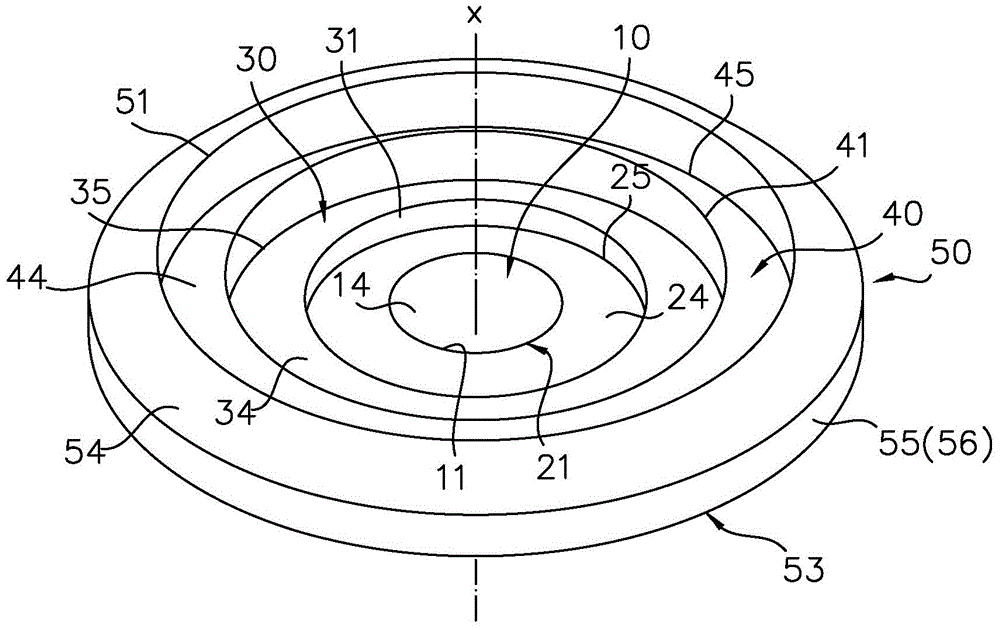

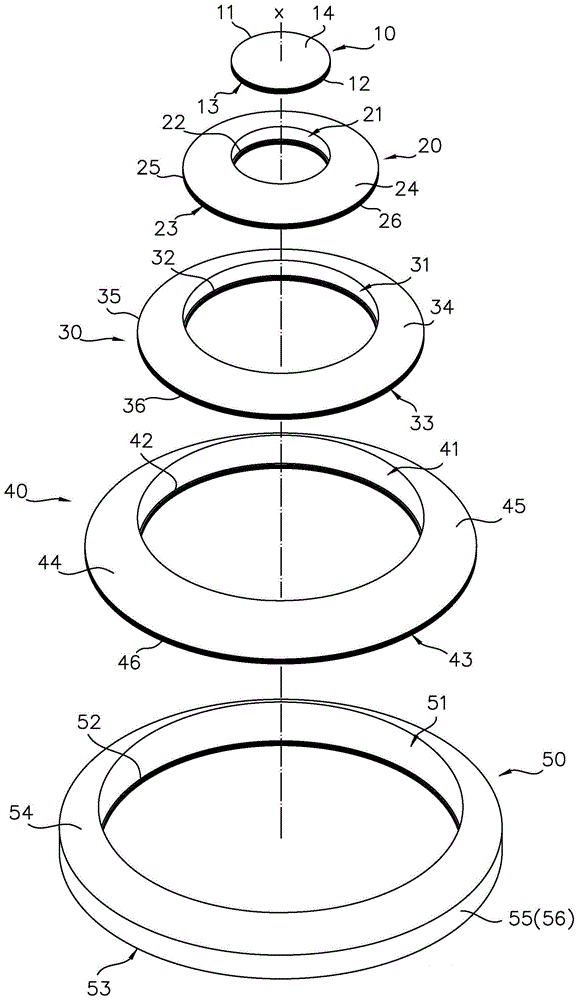

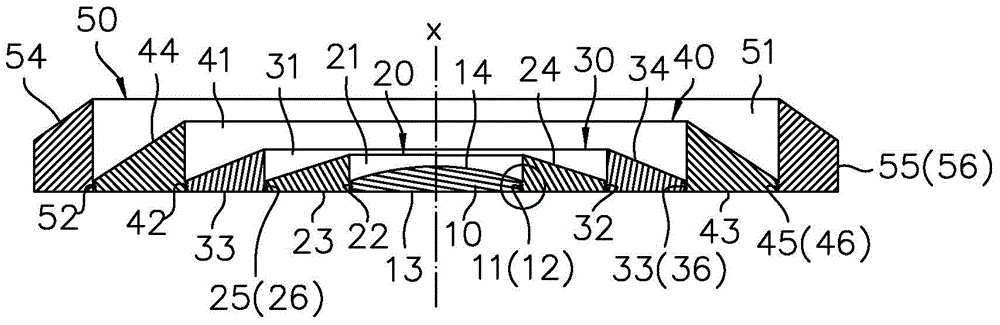

[0072] see figure 1 , figure 2 and image 3 In the splicable and combined optical element structure of the present invention, a Fresnel optical lens or optical element is selected as an illustrative embodiment. The optical element includes a combination of a light-guiding base and at least one light-guiding body, generally denoted by reference numerals 10 and 20 respectively; the light-guiding base 10 and the light-guiding body 20 are made of transparent materials with a geometric profile, and a defined Central reference axis χ. In the adopted embodiment, the light guide base 10 is in the form of a circular plate-shaped body, forming an edge area 11 and a connecting portion 12 arranged on the edge area 11 . The light guide body 10 includes a light guide surface 13 and a light outlet surface 14 corresponding to the light guide surface 13 ;

[0073] figure 2 , image 3 It is shown that the light guide surface 13 forms a planar structure, and the light exit surface 14 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com