Method for distinguishing damage degree of C/C (Carbon-carbon) composite material structure based on acoustic emission technique

An acoustic emission technology and composite material technology, applied in the field of aerospace non-destructive testing, can solve problems such as plastic deformation and deficiencies, and achieve the effects of reducing the risk of testing, avoiding destructive testing, and saving testing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

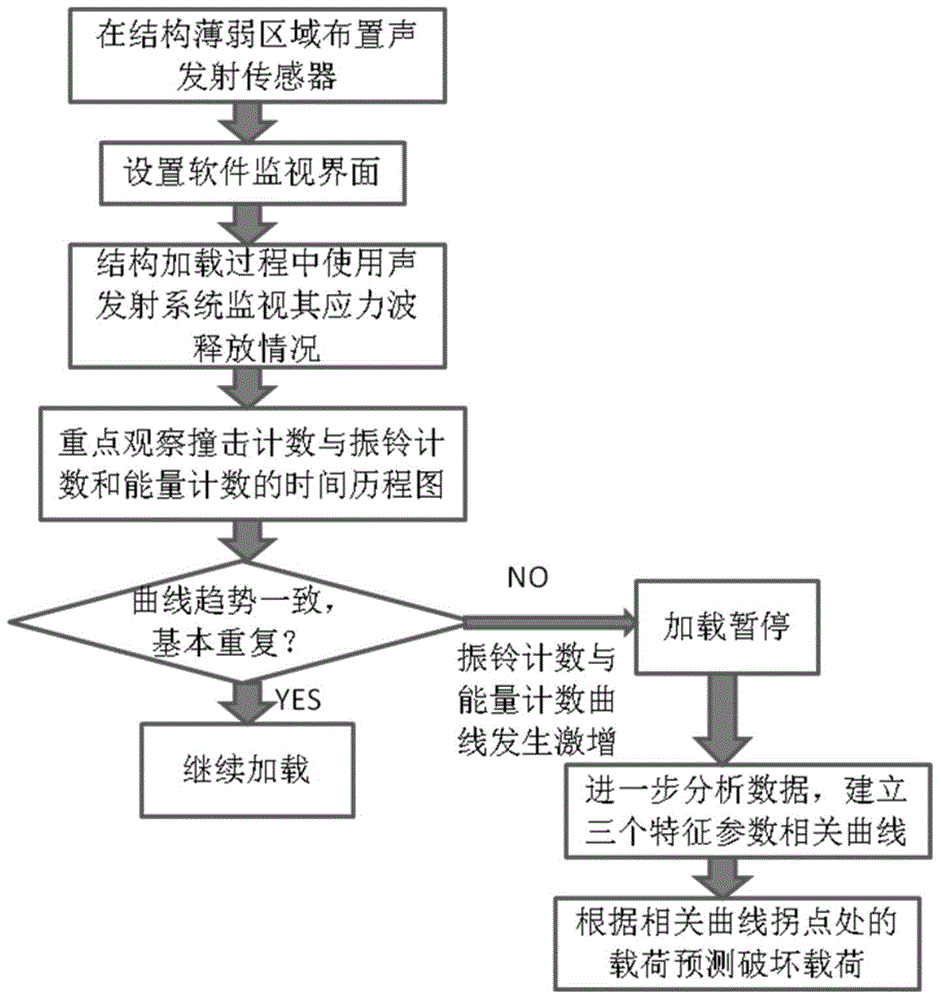

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

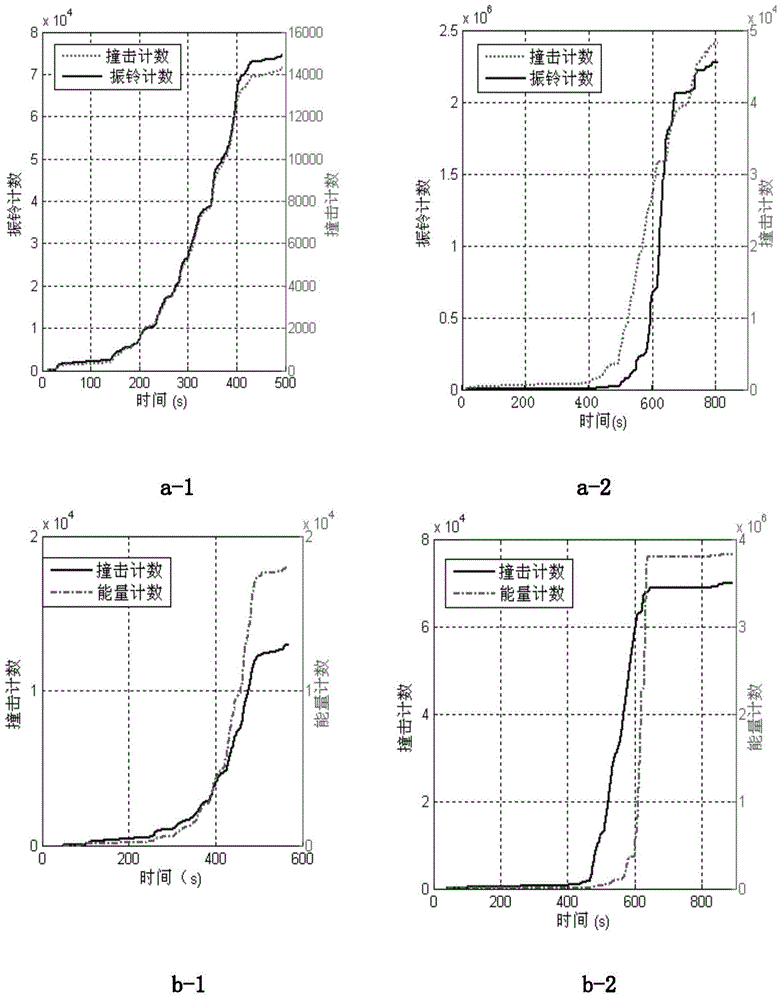

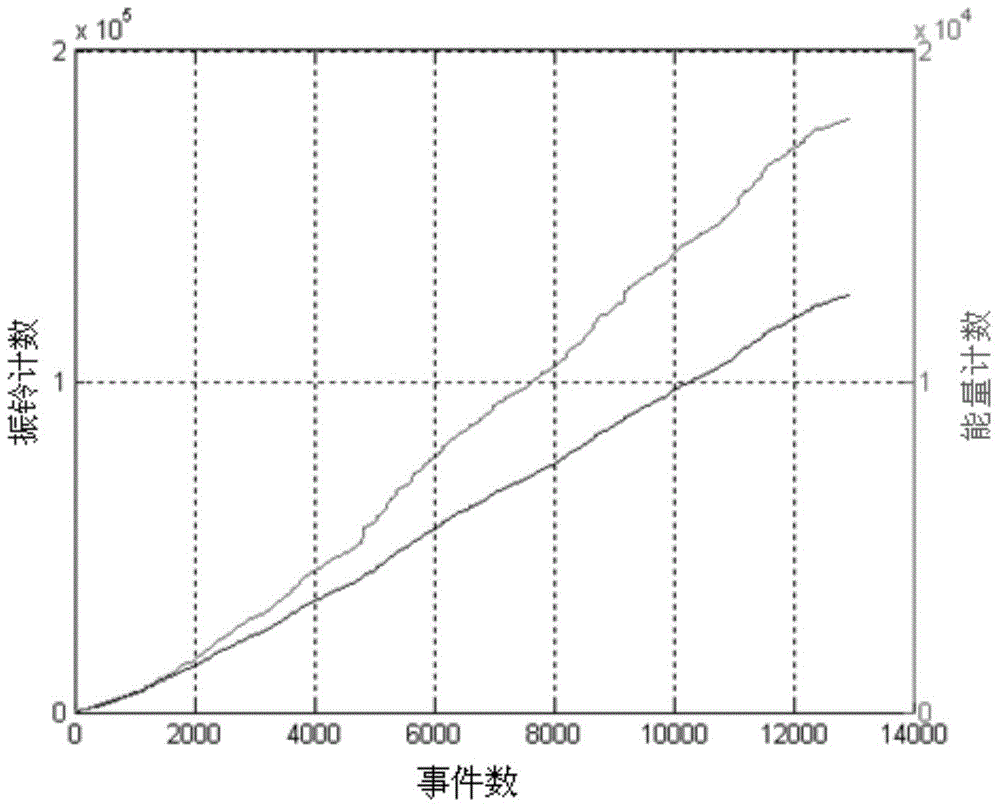

[0027] The principle of the method for judging the damage degree of the C / C composite material structure based on the acoustic emission technology in the present invention is: the relationship between the number of events of the acoustic emission signal and the ringing count and the energy count can reflect the damage of the structure and provide early warning of the structural damage load , specifically the following two points:

[0028] (1) When the damage degree of the C / C braided composite material structure is slight, the occurrence of micro damage sources and the characteristics of stress wave generation obey the stationary probability distribution, and the number of acoustic emission events (when single-channel acquisition or regional positioning method is used, is equivalent to impact counts) and ringing counts and energy counts have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com