MFL (magnetic flux leakage) testing defect three-dimensional imaging method based on magnetic charge distribution reconstruction algorithm

A reconstruction algorithm and three-dimensional imaging technology, applied in the direction of material magnetic variables, etc., can solve the problems of roughness, increase the rationality of constraint conditions, and low precision of three-dimensional quantification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

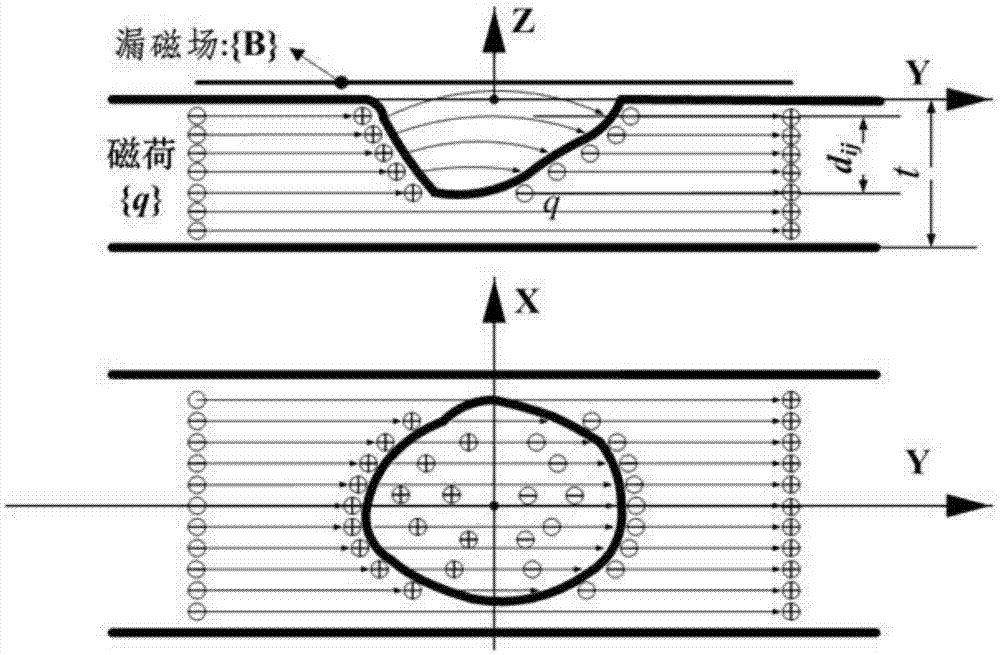

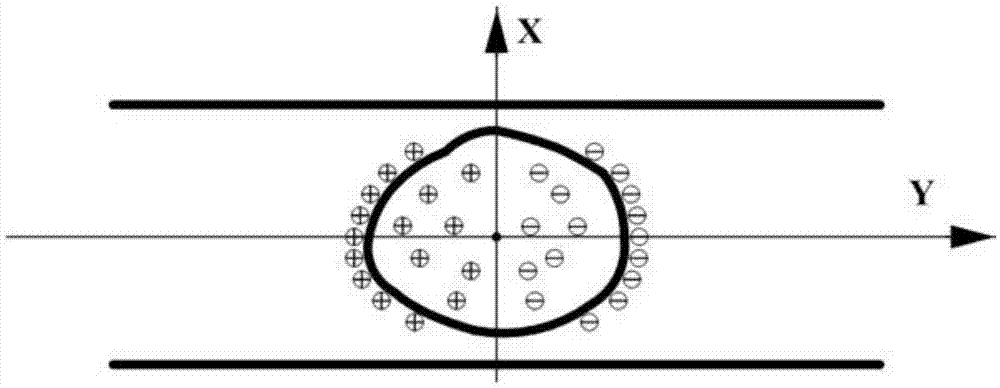

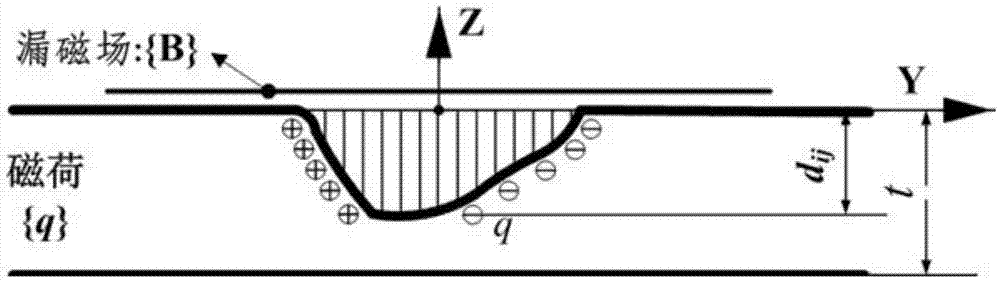

[0025] A three-dimensional imaging method for magnetic flux leakage detection defects based on a magnetic charge distribution reconstruction algorithm, comprising the following steps:

[0026] 1) Carry out saturation magnetization on the defect-free specimen of the ferromagnetic material to be tested, and collect its magnetic flux leakage signal {B};

[0027] 2) Using the two-dimensional magnetic charge distribution reconstruction algorithm to perform inversion calculation on the internal magnetic charge distribution of the non-defective test piece of the material to be tested, and obtain the saturation magnetic charge density per unit volume of the non-defective test piece of the material to be tested;

[0028] 3)

[0029] 3-1) Use the static magnetic field detection probe to detect the leakage magnetic field distribution {B} data in the vertical direction on the surface of the component to be tested, observe the distribution of the leakage magnetic field {B}, and use the obv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com