Centrifugal gas electro-spinning device used for preparing large number of three-dimensional nanofiber scaffolds

A technology of three-dimensional nano-fiber scaffolds, which is applied in fiber processing, electrospinning, textiles and papermaking, etc., can solve the problems of nozzle clogging and low jet start-up voltage, and achieve the advantages of increased thickness, safe operating environment, and favorable cell growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The centrifugal air electrospinning device for preparing a large number of three-dimensional nanofiber scaffolds disclosed in the present invention, when used, first prepares the spinning solution, weighs 1200 mg of PLLA (molecular weight = 200,000 Daltons), dissolves it in 20ml (9: 1, CH 2 Cl 2 / DMF, v / v) solvent, prepared 6% PLLA solution, sealed with parafilm, magnetically stirred for 4 hours, and set aside.

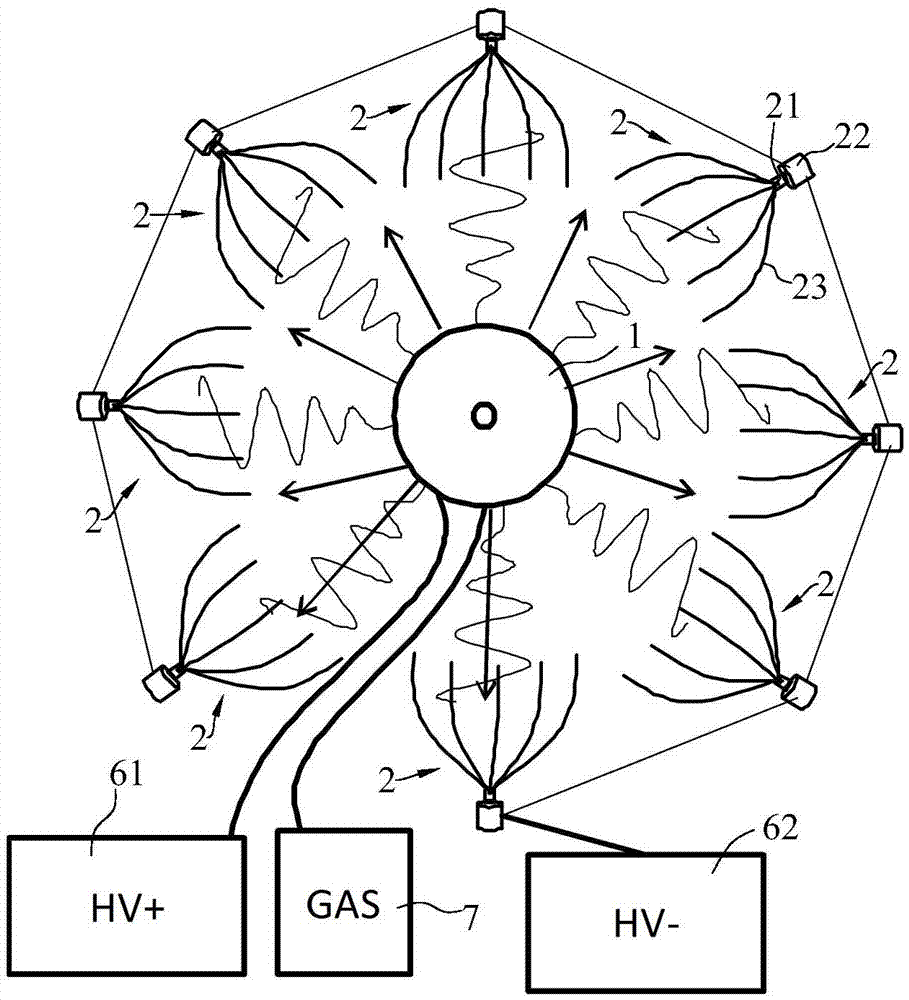

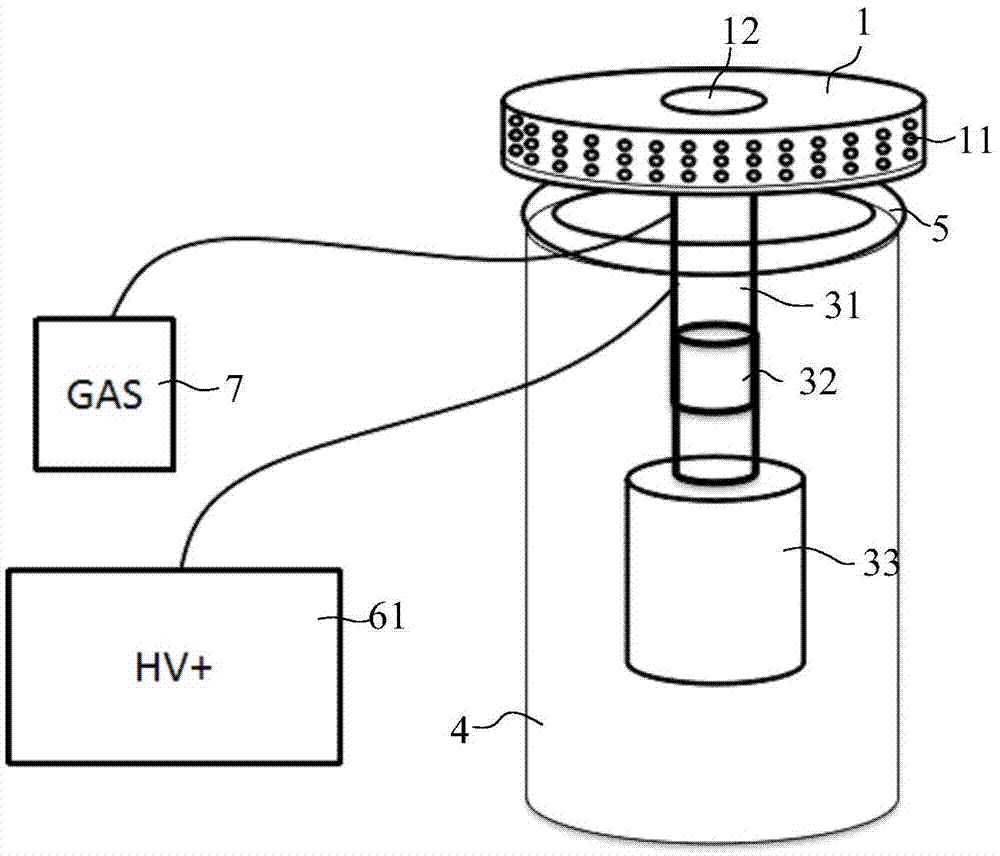

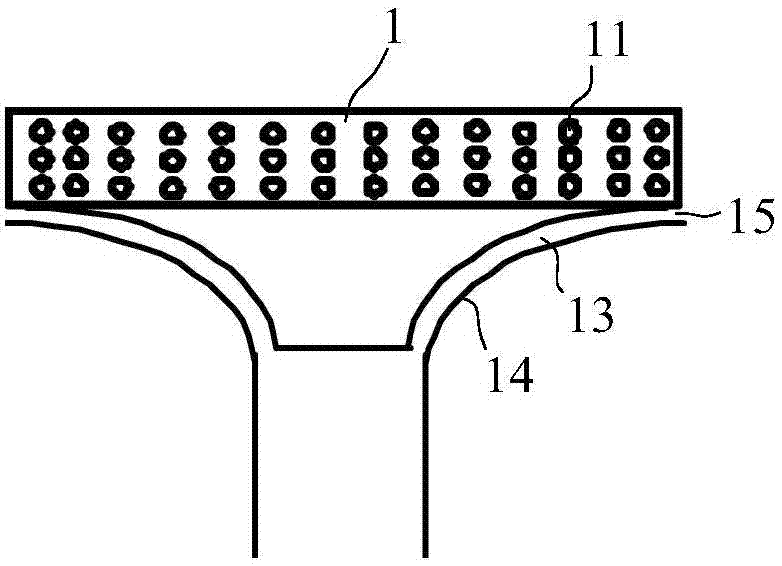

[0033] The PLLA solution is loaded into the feed port 12, the high-voltage positive pressure power supply 61, the air supply device 7 are connected with the centrifugal nozzle 1, and a plurality of open rotary receiving devices 2 are respectively connected with the high-voltage negative pressure power supply 62 through the negative pressure power supply line to adjust the centrifugation. The distance between the nozzle 1 and the open rotary receiving device 2 is 10cm, turn on the second motor switch of the open rotary receiving device 2, turn on the high-volta...

Embodiment 2

[0035] The centrifugal air electrospinning device for preparing a large number of three-dimensional nanofiber scaffolds disclosed in the present invention uses polylactic acid as a raw material, and 10 grams of polylactic acid is added to the feed port 12, and the high-voltage positive pressure power supply 61 is connected to the centrifugal nozzle 1. A plurality of open rotary receiving devices 2 are respectively connected to negative high voltage power supply 62 through negative voltage power lines, adjust the distance between the centrifugal nozzle 1 and the open rotary receiving device 2 to be 10 cm, and then turn on the switch of heating device 5 to make the polylactic acid Heat the centrifugal nozzle 1 to a molten state, turn on the second motor switch of the open rotary receiving device 2, turn on the switch of the high-voltage positive voltage power supply 61 and the negative high-voltage power supply 62, and adjust the output positive voltage to be 5KV DC high voltage, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com