Soluble temporary plugging material for oil-gas well fracture, temporary plugging agent, fracturing fluid and preparation method thereof

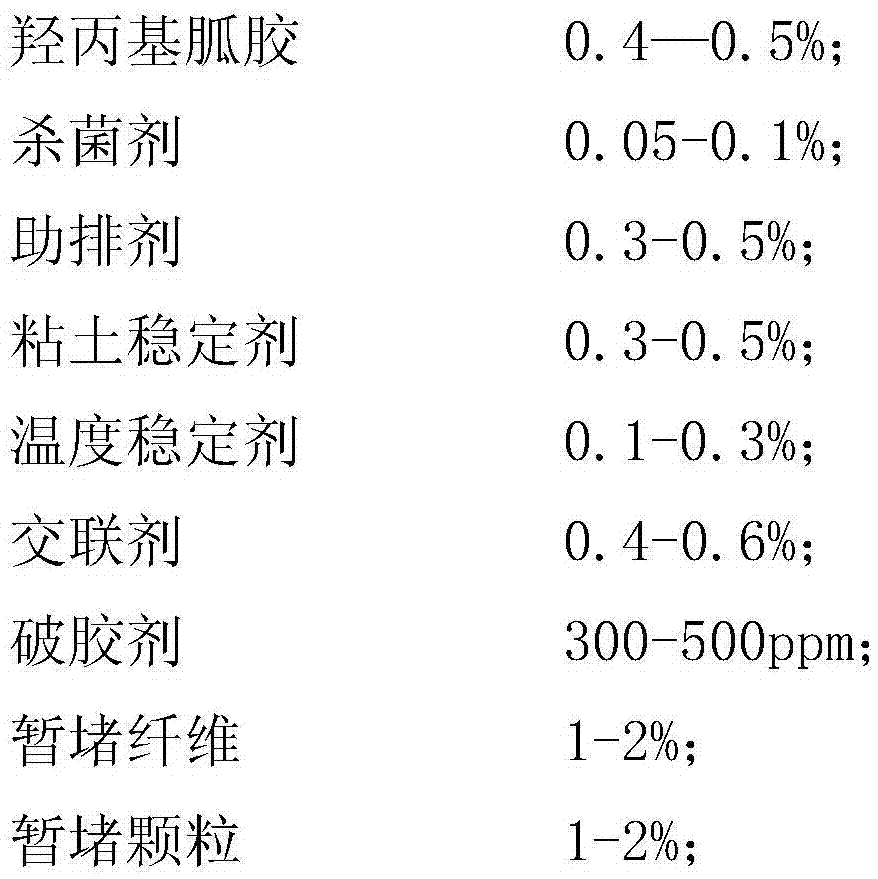

A soluble technology for oil and gas wells, applied in the field of fracturing fluid and its preparation, soluble temporary plugging materials for oil and gas well fracturing, and temporary plugging agents, which can solve formation damage, increase construction period, and poor solubility of cross-linked polymers and other problems, to achieve the effects of less damage to the formation, increased production, and good temporary blocking and steering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

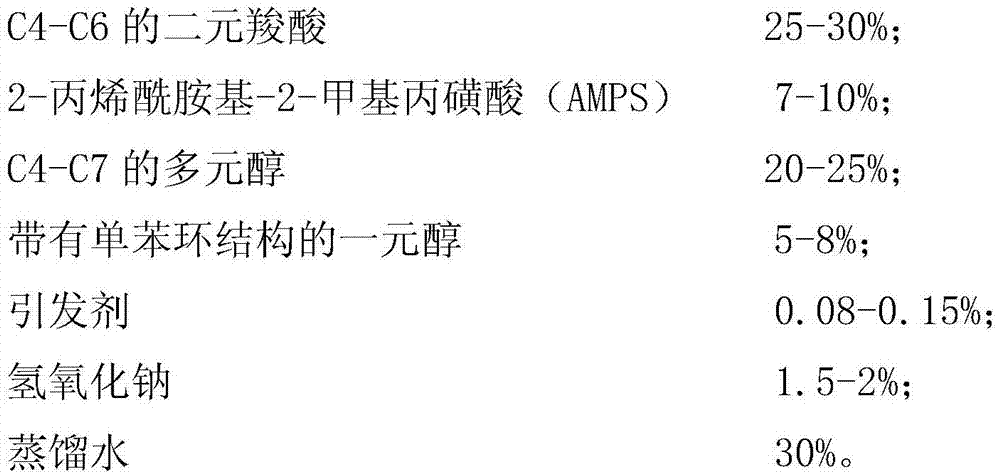

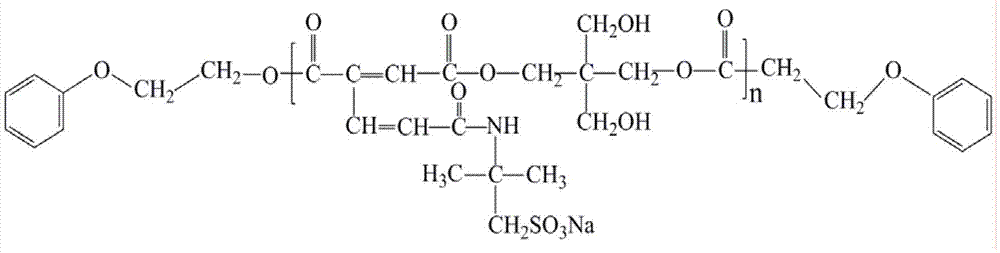

[0029] Nitrogen was passed through the reaction system to replace the air, and then fumaric acid (fumaric acid) and pentaerythritol monomers were added into a four-necked round-bottomed flask according to the mass ratio and stirred, wherein 98.5 g of fumaric acid was added into 100 g of distilled water to fully dissolve , add 110 g of pentaerythritol; then add 0.32 g of initiator and gradually heat the system to 100 ° C, after 25 min of heat preservation, add AMPS solution neutralized with sodium hydroxide to the system (dissolve with distilled water, add 25 g of AMPS to 25 g of distilled water, then add 4 g sodium hydroxide). Then the temperature of the system was raised to 140°C and kept for 0.5h. Then, 15 g of phenoxyethanol was added to the reaction system for reaction, and 0.08 g of initiator was added and the temperature was raised to 165° C., and the temperature was lowered after 2 hours of reaction. After the reaction is completed, the obtained product is purified and...

Embodiment 2

[0033] Nitrogen was passed through the reaction system to replace the air, and then itaconic acid and trimethylolpropane monomers were added into a four-necked round-bottomed flask according to the mass ratio and stirred, wherein 105g of itaconic acid was fully dissolved in 100g of distilled water, and trimethylolpropane was added Methylpropane 97g; then add 0.30g initiator and gradually heat up the system to 105°C, keep warm for 30min and add AMPS solution neutralized with sodium hydroxide to the system (dissolve with distilled water, add 21g AMPS to 30g distilled water, then add 4g sodium hydroxide). Then the temperature of the system was raised to 150°C and kept for 0.5h. Then, 14.5 g of phenoxyethanol was added to the reaction system for reaction, and 0.12 g of initiator was added and the temperature was raised to 180° C., and the temperature was lowered after 2 hours of reaction. After the reaction is completed, the obtained product is purified and dried to obtain the pr...

Embodiment 3

[0038] It is formed by melt spinning method. The soluble temporary plugging material chip obtained in Example 1 is heated and melted into a melt in a screw extruder, and enters the spinning machine after the pre-spinning preparation process, and the spinning melt is quantitatively and continuously melted by a spinning pump (metering pump). , Extruded evenly from the fine holes of the spinneret, then cooled and solidified in the air to form primary fibers, and then cut into fibers with a length of 5-10mm to obtain temporary plugging fibers.

[0039]The soluble temporary plugging material obtained in Example 1 was heated, melted and extruded by a screw extruder, cut and granulated by a granulator, and shaped into particles with a particle size of 5-8 mm to obtain temporary plugging particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com