Water-soluble temporary plugging agent for oil and gas well fracturing temporary plugging diversion and preparation method thereof

A water-soluble, temporary plugging agent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as affecting the production process, unfavorable oil and gas production, and unfavorable flowback, and achieve significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

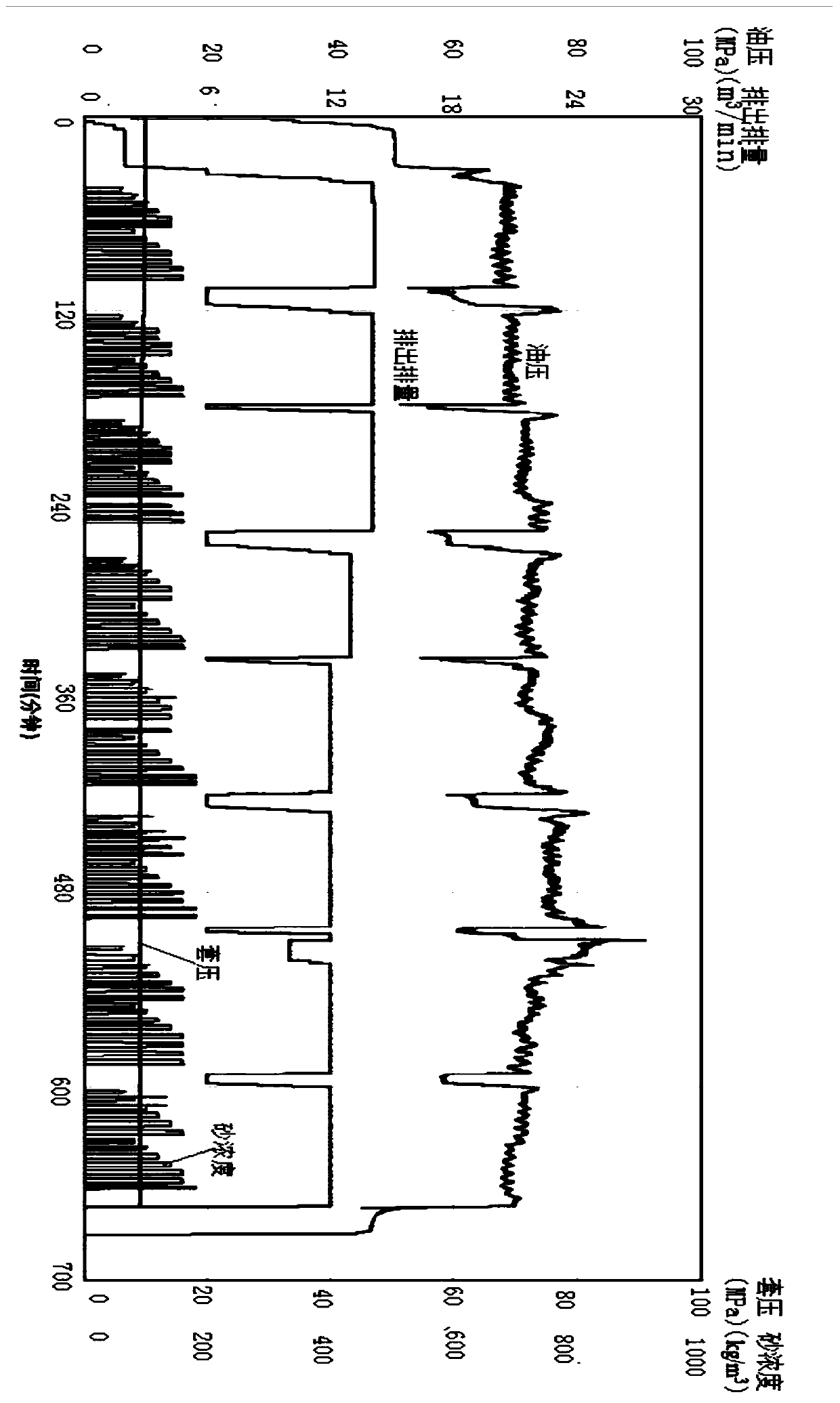

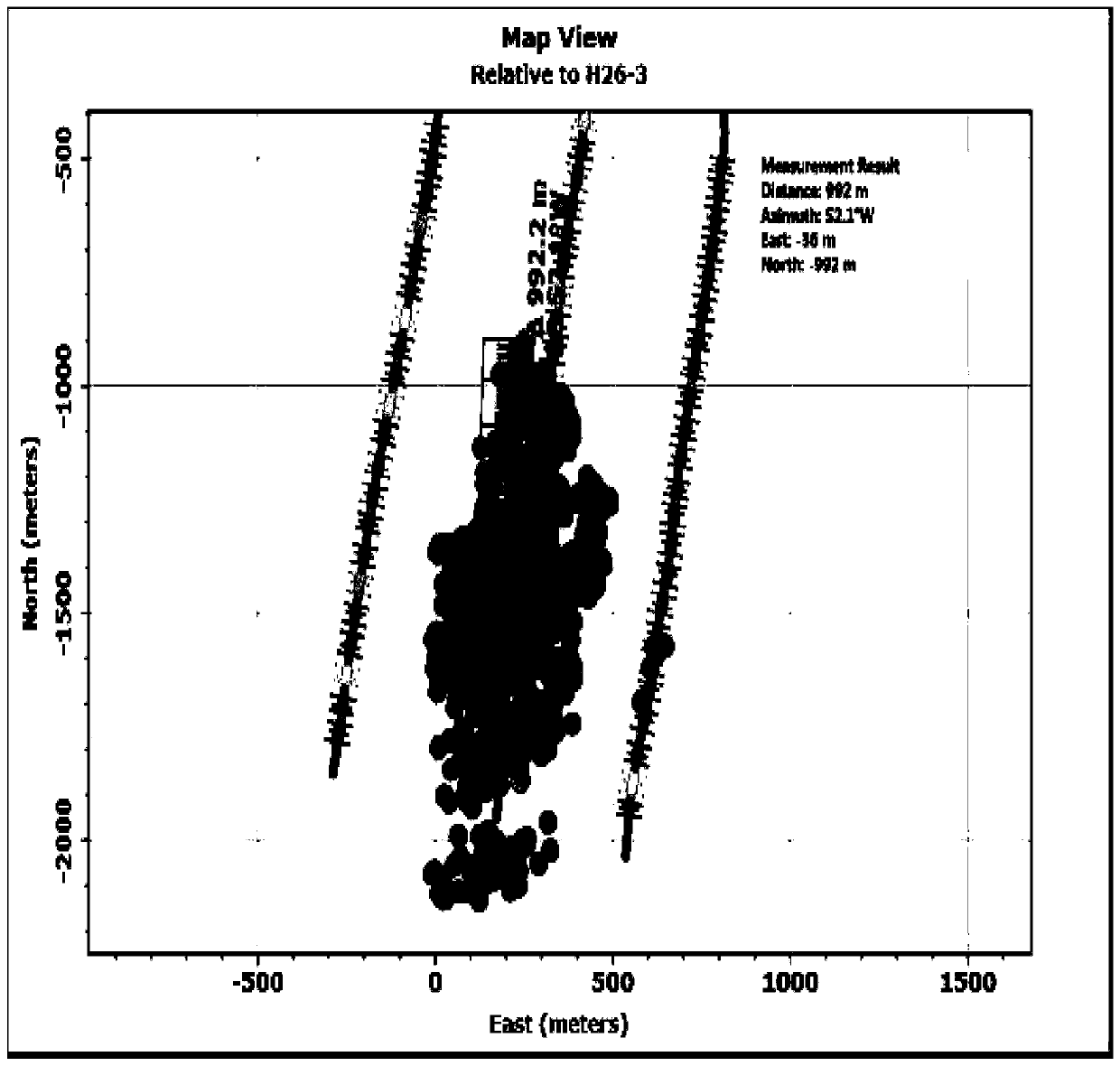

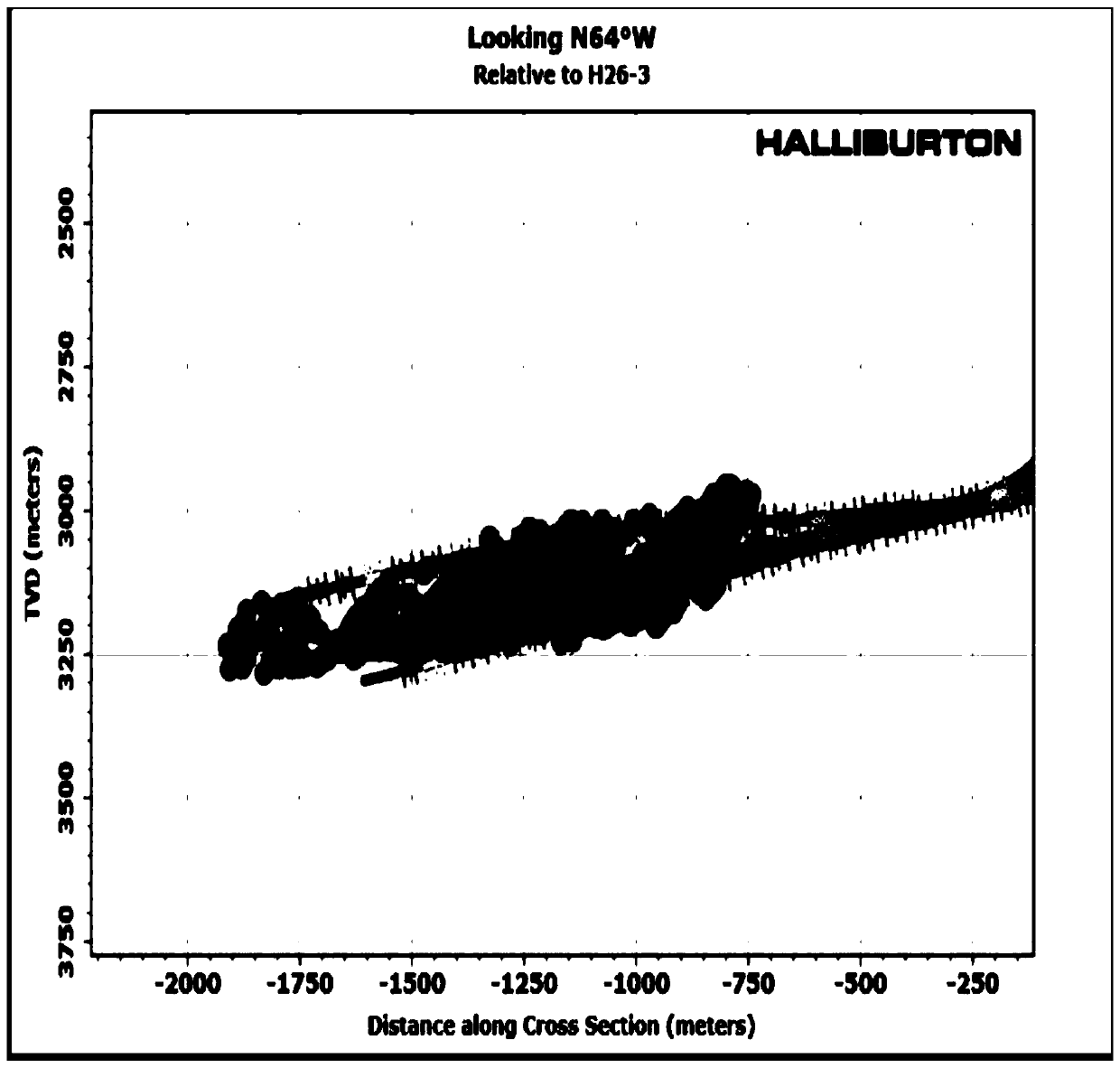

Image

Examples

Embodiment 1

[0031] Add 100 grams of distilled water to a 500-ml flask, replace the air with nitrogen, then add 80 grams of acrylic acid, 25 grams of sodium methacrylate and 64 grams of N-vinylpyrrolidone into the flask and start stirring, then add 0.04 grams of Ammonium persulfate is used as an initiator, and the temperature of the reaction system is gradually raised to 105° C., and after 30 minutes of constant temperature reaction, 1-2 grams of sodium hydroxide is added to the system to adjust the pH value to 7-8. Then the temperature of the system was raised to 150° C. and the reaction was carried out at constant temperature for 1.0 h. Then add 21 grams of polyoxyethylene allyl ester into the flask, and raise the temperature to 180°C, then add 0.04 grams of sodium bisulfite as an initiator, continue the reaction for 2 hours, then cool down to 80°C, and add 5 grams of nano-modifier Potassium silicate, after stirring and reacting for 30 minutes, the obtained product is purified and dried ...

Embodiment 2

[0035] Add 100 gram distilled water in the flask of 500 milliliters, blow nitrogen to replace air, then 90 grams 10-hydroxyl-2-decenoic acid, 20 grams sodium methacrylate and 60 grams N-vinylpyrrolidone are added in the flask and Start stirring, then add a mixture of 0.04 grams of ammonium persulfate and sodium bisulfite as an initiator, and gradually raise the temperature of the reaction system to 100°C, and then add 1-2 grams of sodium hydroxide to the flask to adjust the pH value to 7 -8. Then the temperature of the reaction system was raised to 155° C. and reacted at a constant temperature for 1.0 h. Then 20 grams of polyoxyethylene allyl ester was added to the flask, and the temperature was raised to 185°C, and then a mixture of 0.04 grams of ammonium persulfate and sodium bisulfite was added as an initiator, and the reaction was continued for 2 hours, and then the temperature was lowered to 70°C, and added 6 grams of nano-modifier nano-aluminum hydroxide, stirred and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com