Dilution-free alkali-resistant seal primer for external wall and preparation method thereof

A sealing primer and non-dilution technology, which is applied in the direction of coating, etc., can solve the problems of unsatisfactory sealing effect of alkali-resistant sealing primer, cumbersome construction process, uncontrollable adhesion, etc., to achieve excellent water permeability, convenient construction, Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

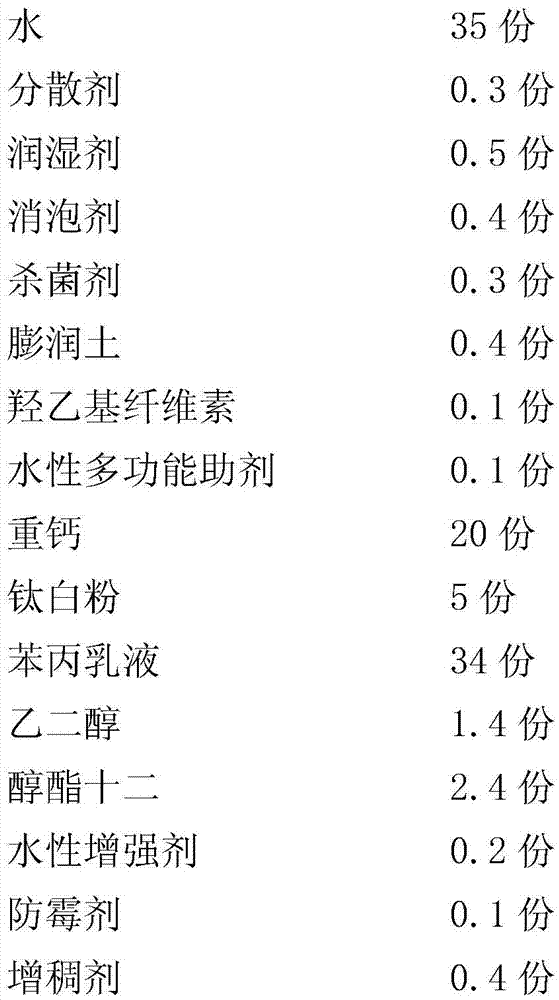

[0026] A non-dilution and alkali-resistant sealing primer for exterior walls, which is prepared from the following components and weight / number ratios:

[0027]

[0028] A preparation method for an exterior wall non-diluted alkali-resistant sealing primer, which comprises the following steps in sequence:

[0029] (a), add 35 parts of water into the dispersing tank, add 0.3 part of dispersant, 0.5 part of wetting agent, 0.4 part of defoamer, 0.3 part of fungicide, 0.4 part of bentonite and 0.1 part of hydroxyethyl cellulose, stirred for 1-3 minutes.

[0030] (b) Then, add 0.1 part of water-based multifunctional additive, increase the rotation speed to 600-800r / min, and stir for 1-3 minutes.

[0031] (c), then, add 20 parts of heavy calcium and 5 parts of titanium dioxide, continue to increase the speed to 1000-2000r / min, stir for 10-20 minutes, then add 34 parts of styrene-acrylic emulsion, reduce the speed to 600-1000r / min , stir for 3-5 minutes.

[0032] (d) Finally, at...

specific Embodiment example 2

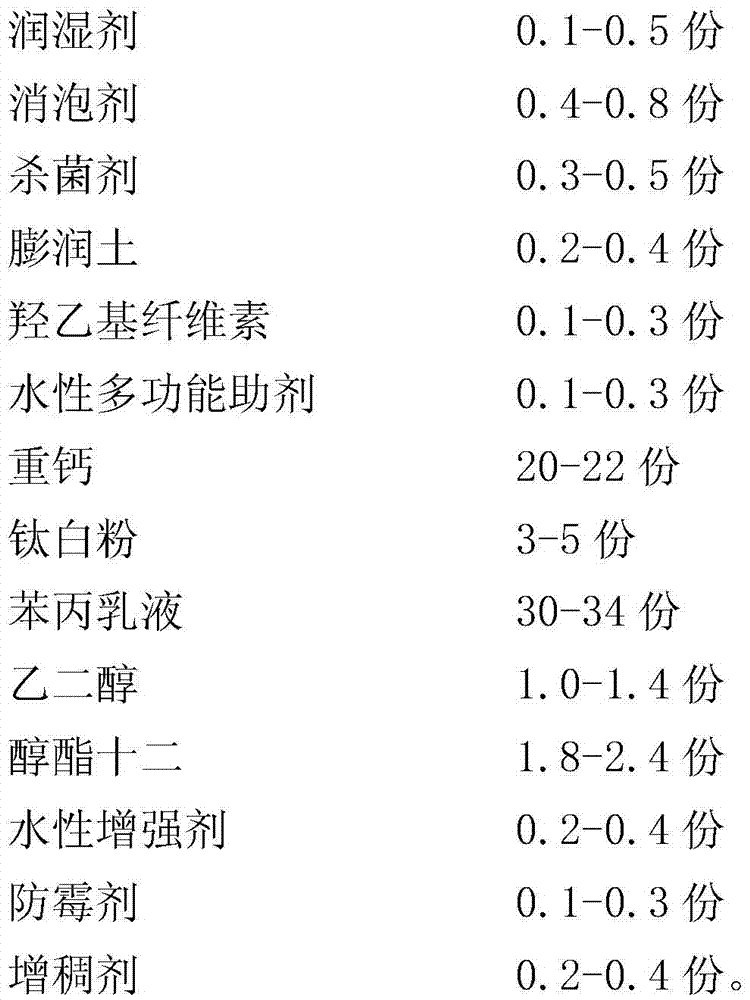

[0034] A non-dilution and alkali-resistant sealing primer for exterior walls, which is prepared from the following components and weight / number ratios:

[0035]

[0036] A preparation method for an exterior wall non-diluted alkali-resistant sealing primer, which comprises the following steps in sequence:

[0037] (a), add 39 parts of water into the dispersion tank, add 0.5 part of dispersant, 0.1 part of wetting agent, 0.8 part of defoamer, 0.5 part of fungicide, 0.2 part of bentonite and 0.3 parts of hydroxyethylcellulose, stirred for 1-3 minutes.

[0038] (b) Then, add 0.3 part of water-based multifunctional additive, increase the rotation speed to 600-800r / min, and stir for 1-3 minutes.

[0039] (c), then, add 22 parts of heavy calcium and 3 parts of titanium dioxide, continue to increase the speed to 1000-2000r / min, stir for 10-20 minutes, then add 30 parts of styrene-acrylic emulsion, reduce the speed to 600-1000r / min , stir for 3-5 minutes.

[0040] (d) Finally, at...

specific Embodiment example 3

[0042] A non-dilution and alkali-resistant sealing primer for exterior walls, which is prepared from the following components and weight / number ratios:

[0043]

[0044] A preparation method for an exterior wall non-diluted alkali-resistant sealing primer, which comprises the following steps in sequence:

[0045](a), add 37 parts of water into the dispersion tank, add 0.4 parts of dispersant, 0.3 parts of wetting agent, 0.6 parts of defoamer, 0.4 parts of bactericide, 0.3 parts of bentonite and 0.2 parts of hydroxyethylcellulose, stirred for 1-3 minutes.

[0046] (b) Then, add 0.2 part of water-based multifunctional additive, increase the rotation speed to 600-800r / min, and stir for 1-3 minutes.

[0047] (c), then, add 21 parts of heavy calcium and 4 parts of titanium dioxide, continue to increase the speed to 1000-2000r / min, stir for 10-20 minutes, then add 32 parts of styrene-acrylic emulsion, reduce the speed to 600-1000r / min , stir for 3-5 minutes.

[0048] (d) Final...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com